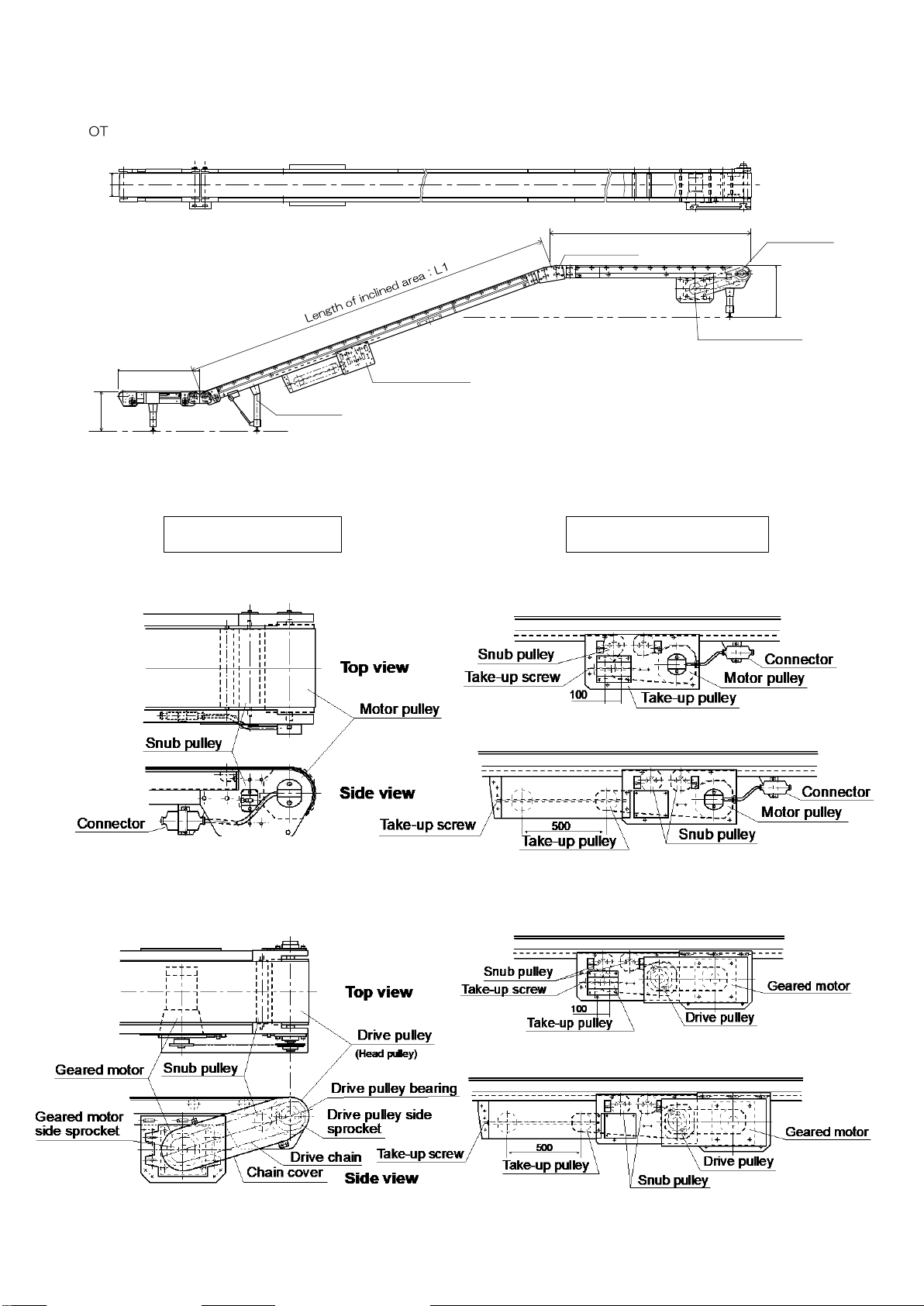

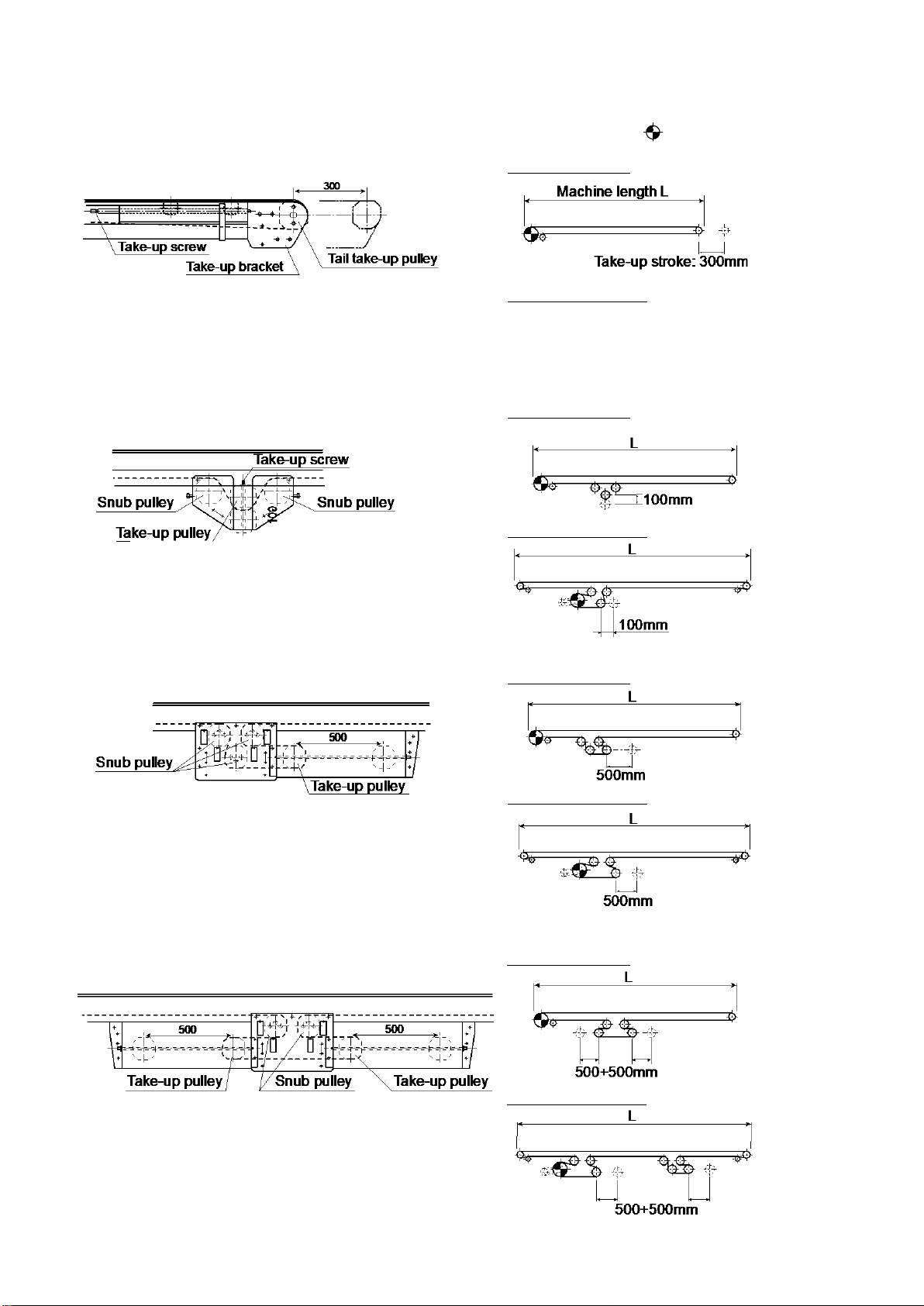

□When using in a high or inclined position:

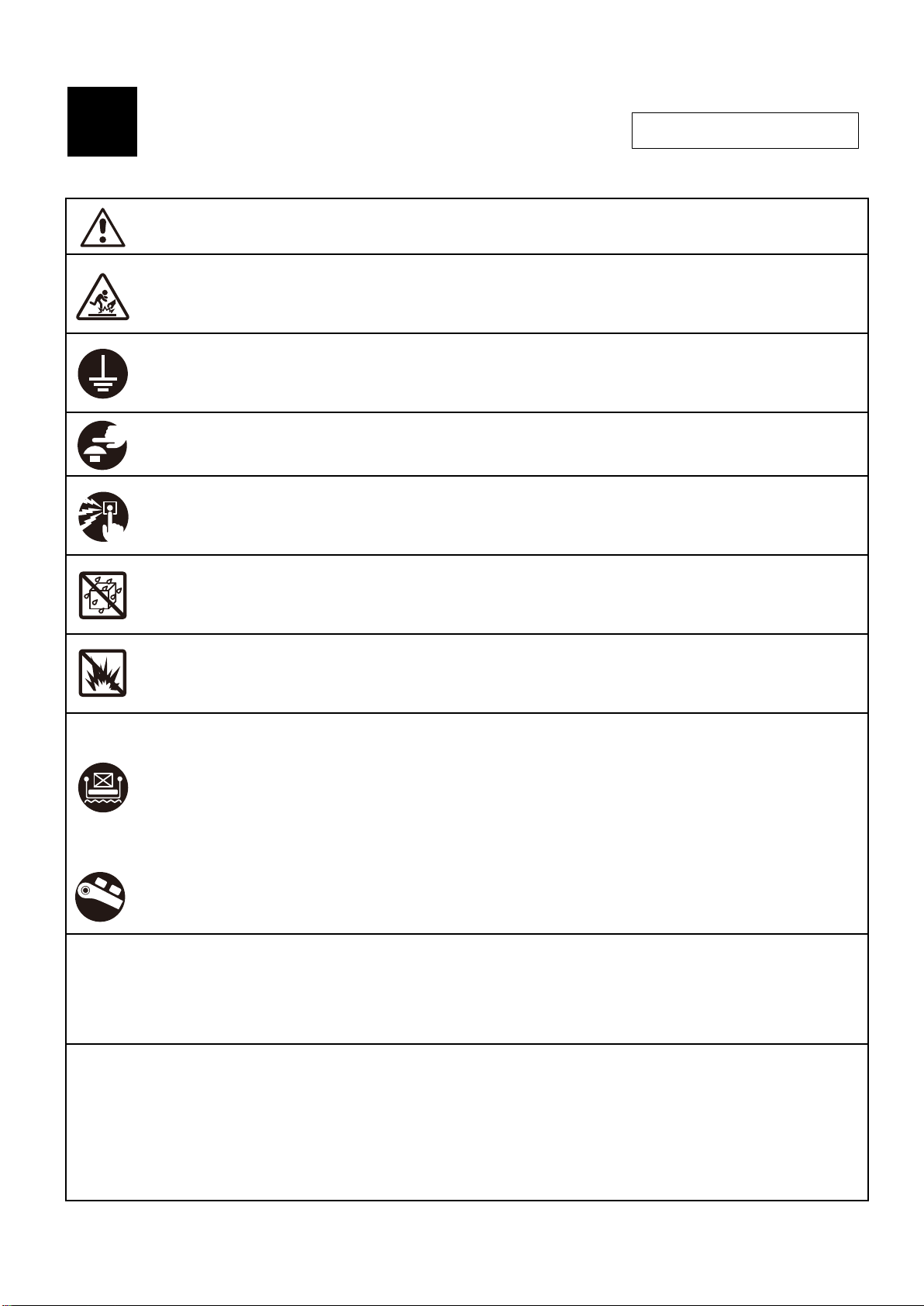

CAUTION : Improper handling of the conveyor may result in physical injury or damage!

■Transport and assembly

When transporting and assembling the conveyor, pay special attention not to drop it in order to

avoid physical injury or damage. When lifting by crane, pay attention to the balance of the conveyor.

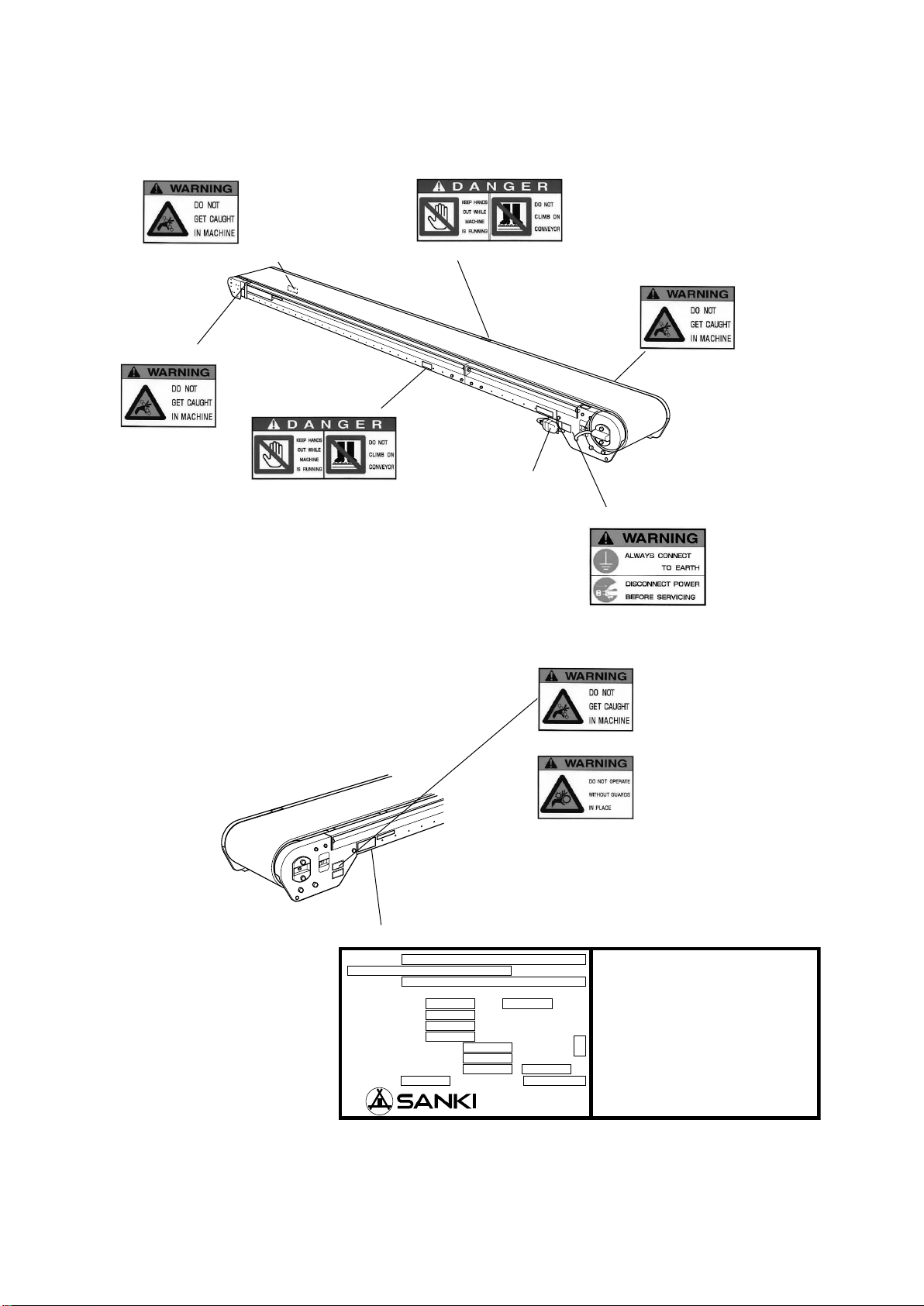

■Earth and leakage breaker

Ensure the conveyor is connected to earth at all times to prevent electric shock. Also ensure that

an earth leakage breaker is connected to the power supply.

■Emergency stop

Install an emergency stop device to immediately stop the conveyor in emergency.

■Start alarm

If it is not possible to supervise the operation of the full length of the conveyor from the operating

position, install a start alarm for increased safety.

■Keep the conveyor dry at all times

Do NOT use the conveyor in wet or humid areas. Do NOT splash liquids onto the conveyor. Use

the waterproof type (optional) if necessary.

■Do NOT use in an explosive atmosphere

(Avoid explosive gas, explosive dust, etc.)

■Lower cover and guard

Install the optional lower cover or guard in order to prevent entry under the conveyor.

■Guide rail, top and side covers

To prevent objects from falling off the conveyor, install the optional guide rail, top and/or side

covers.

■Braking system

When using the conveyor on an incline, it is recommended that an optional braking system be

installed, in order to prevent reverse or other incorrect running of the conveyor.

■Environmental conditions

Ambient temperature

Ambient humidity

Atmosphere

Elevation

NOTE:

●Using the conveyor in a strong electric field (eg near broadcasting devices or high- frequency welding

machinery/equipment) could cause the conveyor to malfunction. In this case, install the conveyor at a

sufficient distance. Alternatively shield completely to avoid any interference with the conveyor.

●Using an inverter to this machine could cause other machines to get effects of high-frequency. In this

case, install the conveyor at a sufficient distance or shield completely.

:0℃ to +40℃

:RH 90% max(Avoid condensation)

:Indoor(Avoid corrosive gases, dust, etc.)

:1,000m or less