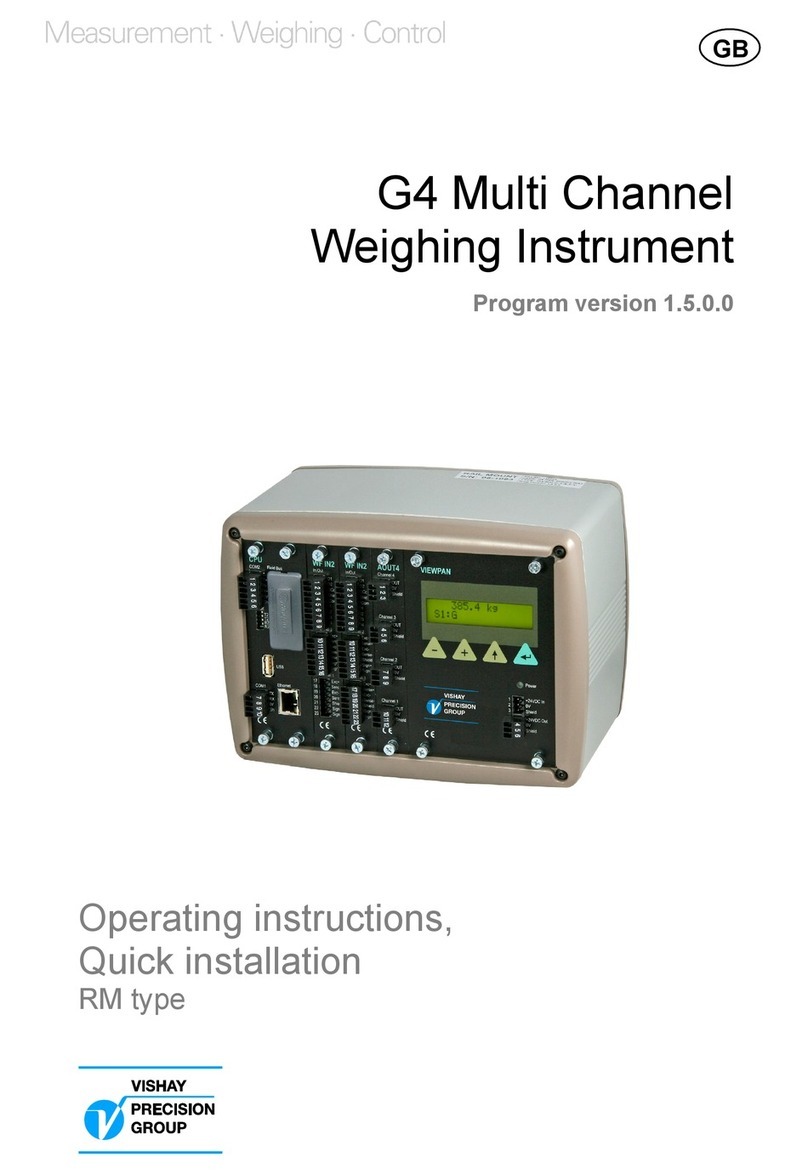

G4 Multi Channel Weighing Instrument

1. Introduction

General .............................................1-1

Functions ..........................................1-2

Maintenance .....................................1-4

Safety information ............................1-4

Technical data ..................................1-5

Ordering information ......................1-12

2. Installation

Mechanical installation .....................2-1

Electrical installation .........................2-2

CPU unit............................................2-3

VIEWPAN module ............................2-5

WF IN, WF IN2 and HS WF2 ...........2-6

AOUT1 and AOUT4 .........................2-9

DIO8 ...............................................2-10

Profibus-DP Fieldbus Adaptor.........2-11

DeviceNet Fieldbus Adaptor ..........2-13

3. Set-up

General .............................................3-1

Operators interface ...........................3-3

Menu structure .................................3-8

Parameters .....................................3-11

Program options .............................3-48

4. Calibration

General .............................................4-1

Common parameters .......................4-2

Data sheet calibration ......................4-4

Table calibration ...............................4-5

Deadweight calibration .....................4-5

5. Operation

General .............................................5-1

Power supply ....................................5-1

Power-up sequence .........................5-1

Weight display ..................................5-2

Security locks ...................................5-3

Taring ...............................................5-4

Gross/Net operation .........................5-5

Zero setting ......................................5-5

Zero-track./Auto. zero setting ...........5-6

Motion ...............................................5-6

Weight printing .................................5-7

Batch report printing .........................5-8

Main menu ........................................5-8

Level supervision ...........................5-10

Setpoint function ............................5-11

Use of inputs and outputs ..............5-12

Filter function .................................5-12

Flow rate ........................................5-14

6. Communication

General ............................................6-1

Serial interface..................................6-1

Modbus RTU Slave ..........................6-1

Modbus TCP Slave ..........................6-2

External I/O.......................................6-3

EtherNet/IP ......................................6-4

Ftp Server.........................................6-9

Modbus protocol ..............................6-9

Fieldbus interface ...........................6-38

Fieldbus and EtherNet/IP Data Def.6-39

Weight printing................................6-52

7. Remote Access

General ............................................7-1

Browser requirements.......................7-1

Using the Remote Access ...............7-2

Security.............................................7-2

Remote Access Login and Logout....7-3

Remote / Local Access.....................7-5

Remote Set-up..................................7-6

Remote Access Maintenance.........7-10

Instrument Restart..........................7-19

8. Maintenance

General ............................................8-1

Diagnostics .......................................8-1

File handling ....................................8-5

Create Backup .................................8-6

Restore Backup ...............................8-6

Set Default........................................8-6

Program Upgrade .............................8-7

Instrument Restart............................8-7

9. Troubleshooting

General.............................................9-1

Error codes ......................................9-1

Appendix

Declaration of Conformity.............App.1

Contents