04

01 The machine will run an auto regen as

required to clear soot from the exhaust

system.

For the regen to commence the machine

must meet certain parameters with regards

to temperature.

When the Auto Regen light illuminates

continue to work the machine normally until

the regen has completed.

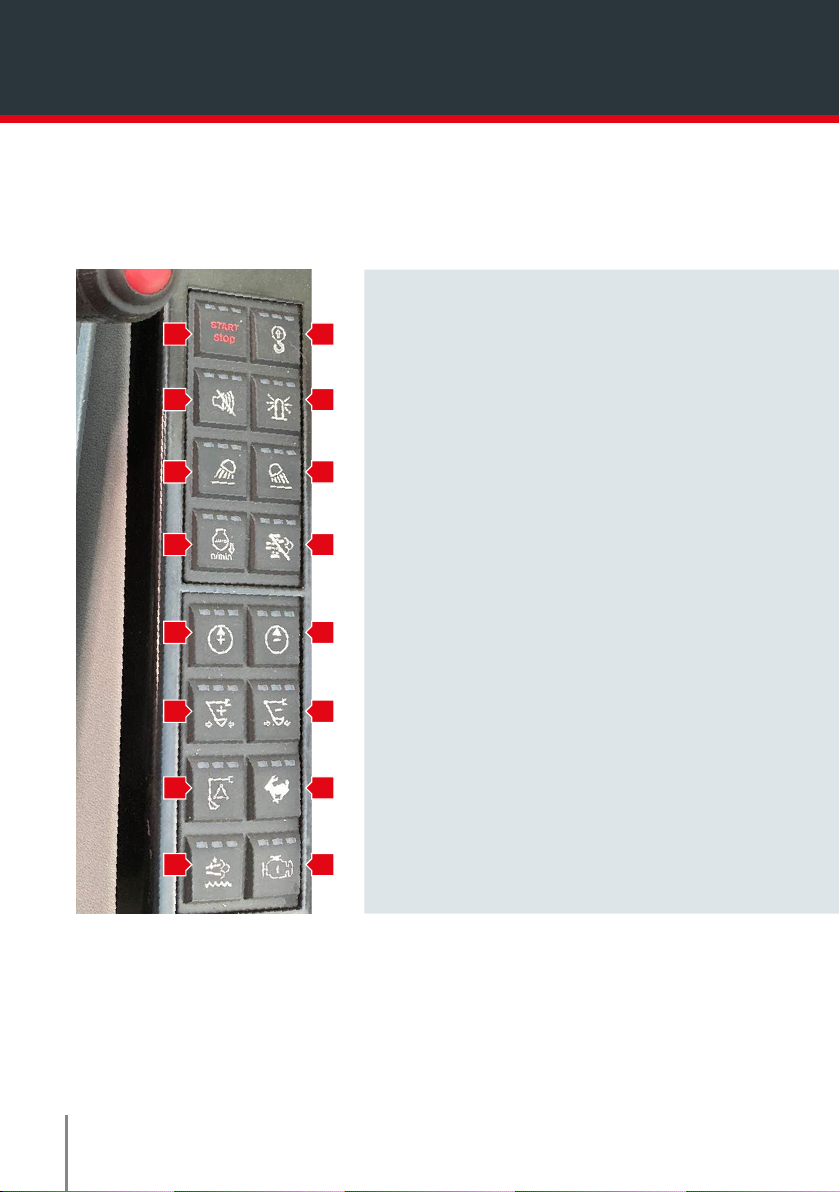

02 A regen can be inhibited in the event that

carrying out the process with high exhaust

temperatures may cause a health and safety

concern, for example the machine is working

next to flammable material.

To inhibit the regen press the Inhibit switch

on the front right hand softkey pad.

The regen will stop and the Regen Inhibit light will illuminate on the display.

The machine can now be moved to a safe area to allow the process to continue.

* DO NOT inhibit regens unnecessarily.

* All inhibits are recorded within the machine ECU.

* Multiple inhibits will lead to a service regen being required or may result in damage to the

exhaust system. Damage caused in this way is NOT covered by warranty.

Exhaust Regeneration

01

02