Sanyo CP10 User manual

Other Sanyo CD Player manuals

Sanyo

Sanyo MCD-S735F User manual

Sanyo

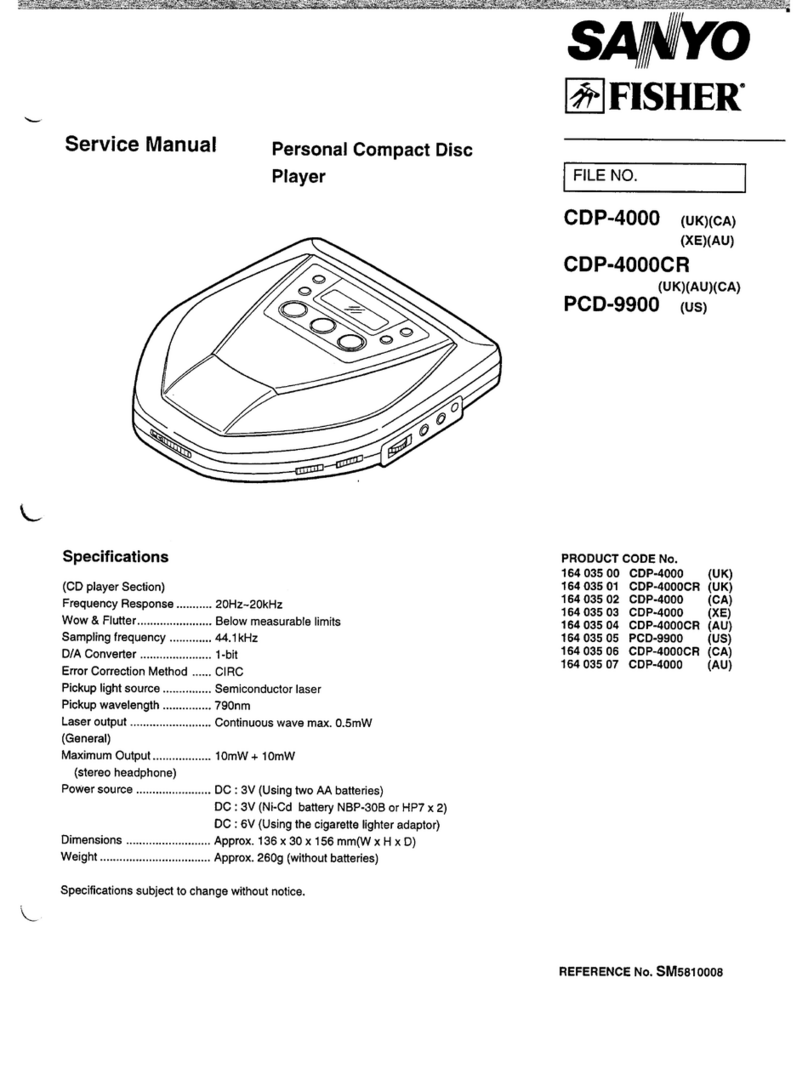

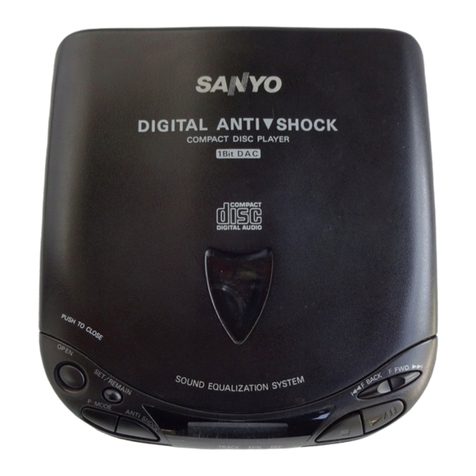

Sanyo CDP-4000 User manual

Sanyo

Sanyo CDP-455 User manual

Sanyo

Sanyo CDP-990 User manual

Sanyo

Sanyo FXD-C200 User manual

Sanyo

Sanyo MCD-Z1F User manual

Sanyo

Sanyo DC-MS1 User manual

Sanyo

Sanyo CDP-4800B User manual

Sanyo

Sanyo FXD-C222 User manual

Sanyo

Sanyo CDP-1000 User manual

Sanyo

Sanyo CDP-M303 User manual

Sanyo

Sanyo FXD-C300 User manual

Sanyo

Sanyo CDP-4000 User manual

Sanyo

Sanyo MCD-X77L User manual

Sanyo

Sanyo CDP-565 User manual

Sanyo

Sanyo mcd-z37f User manual

Sanyo

Sanyo MCD-Z1F User manual

Sanyo

Sanyo CDP-4100CR User manual

Sanyo

Sanyo Excedio CDF-201 User manual

Sanyo

Sanyo MCD-ZX530F User manual