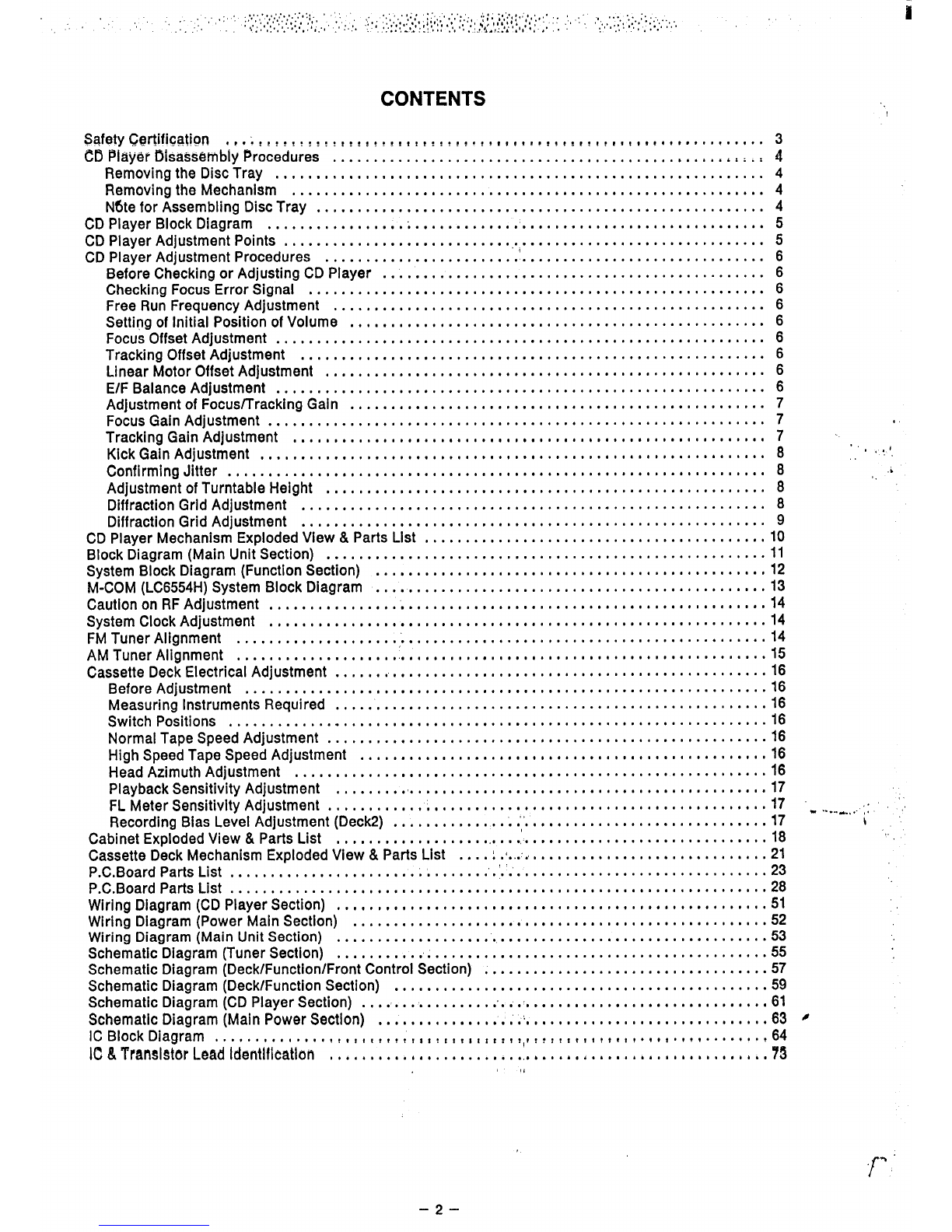

CONTENTS

Safety Certification ,J..~~f~ ~:gg.~*q g**.~!!l L!! !~!,!,,,,, ,,f,ttc!lp ,,!, tt o,,, ,,, ,, . . . .

CD PiaY6r Disassembly Procedures .................$, .,... . . . . . . . . . . . . . . . . ,., ,.,.’, ::.:

Removing the Disc Tray ,,, ,,.,, ,,, ,0,,, .,, .,,., ,., ..,.. ,. .,.0.. 0.......,0...,.0. ...

Removin~the Mechan~sm ,. .,0.,. ,, .,,.0. ., ..,.., .$

N6te for Assembling Disc Tray ..... ...... ..... .......

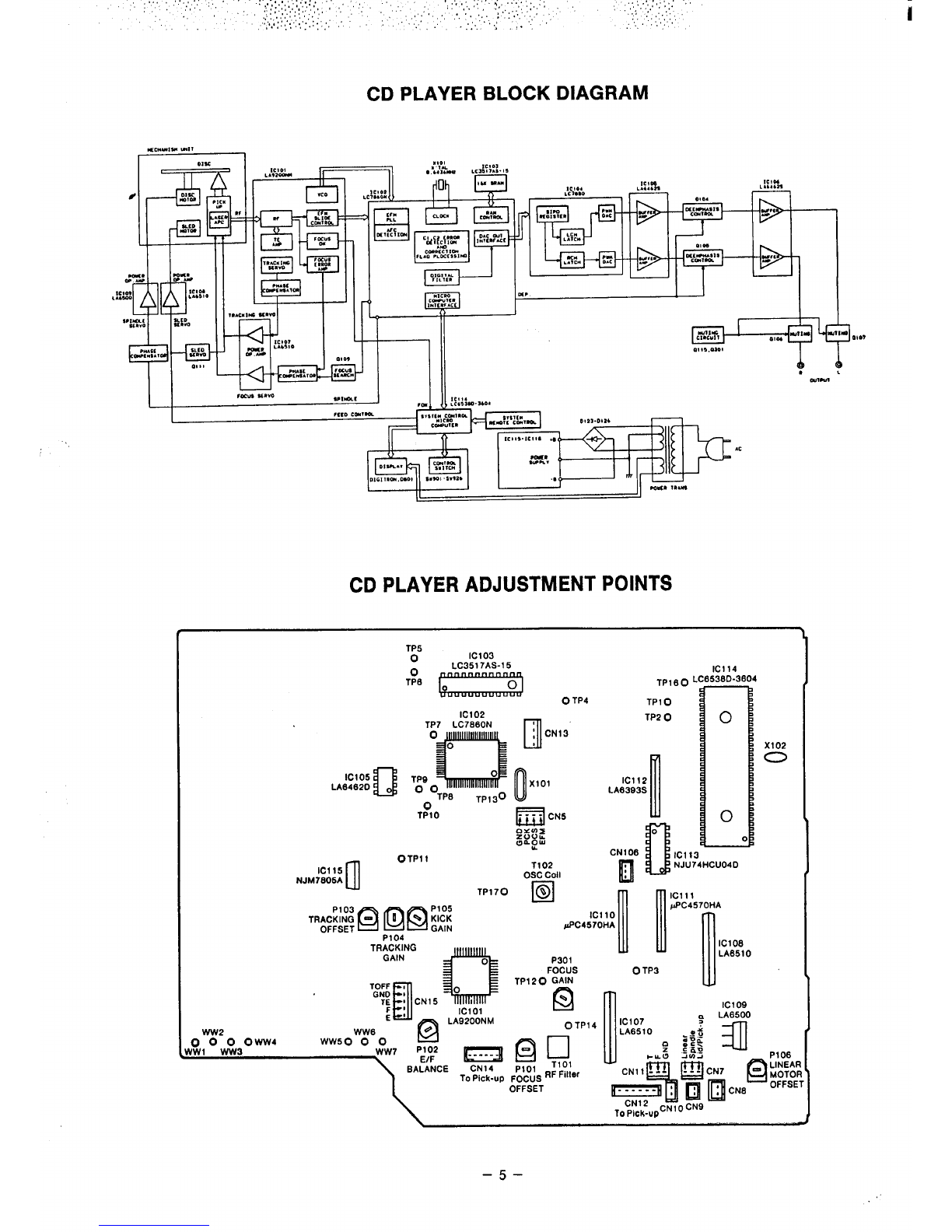

CD Player Block Diagram ,, ..0..,. ....................

CD Player Adjustment Points ...........................

CD Player Adjustment Procedures ......................

Before Checking or Adjusting CD Player ...............

. . . . . . . . . . 6....................

. . . ...0.. .....................0

...... ..... ....... ............ ..

....................0 ...,,.. . . . .

...............................

......0. .......................

Checking Focu{ErrorSignal .................................................

Free Run Frequency Adjustment . . .......

... !.... . ..0..0. ...................................

Setting of Initial Position of Volume ,., ,., ,. ,0 .,..,. ., ..,... ,,, ,, ... .,0, . . . . ,. ...,., . . .

Focus Offset Adjustment . . ., ..0... . . . . . . . . .. 0,.,.. .0 .0.... . . . . . . . . ., . . ...0 .. ......0.

Tracking Offset Adjustment ... ..,.. ,, .,,.,. . . . . . . . . . . . . . . . . . . . . . . . . ,. 0,.0.. .........

Linear Motor Offset Adjustment ,., ..,.. . . . . . . . . . . . . . . . . . . . . . . . . . . ...0.. .......... 000.

E/F Balance Adjustment ....................................,0 ...,,,. ,., ,. ,0., ......

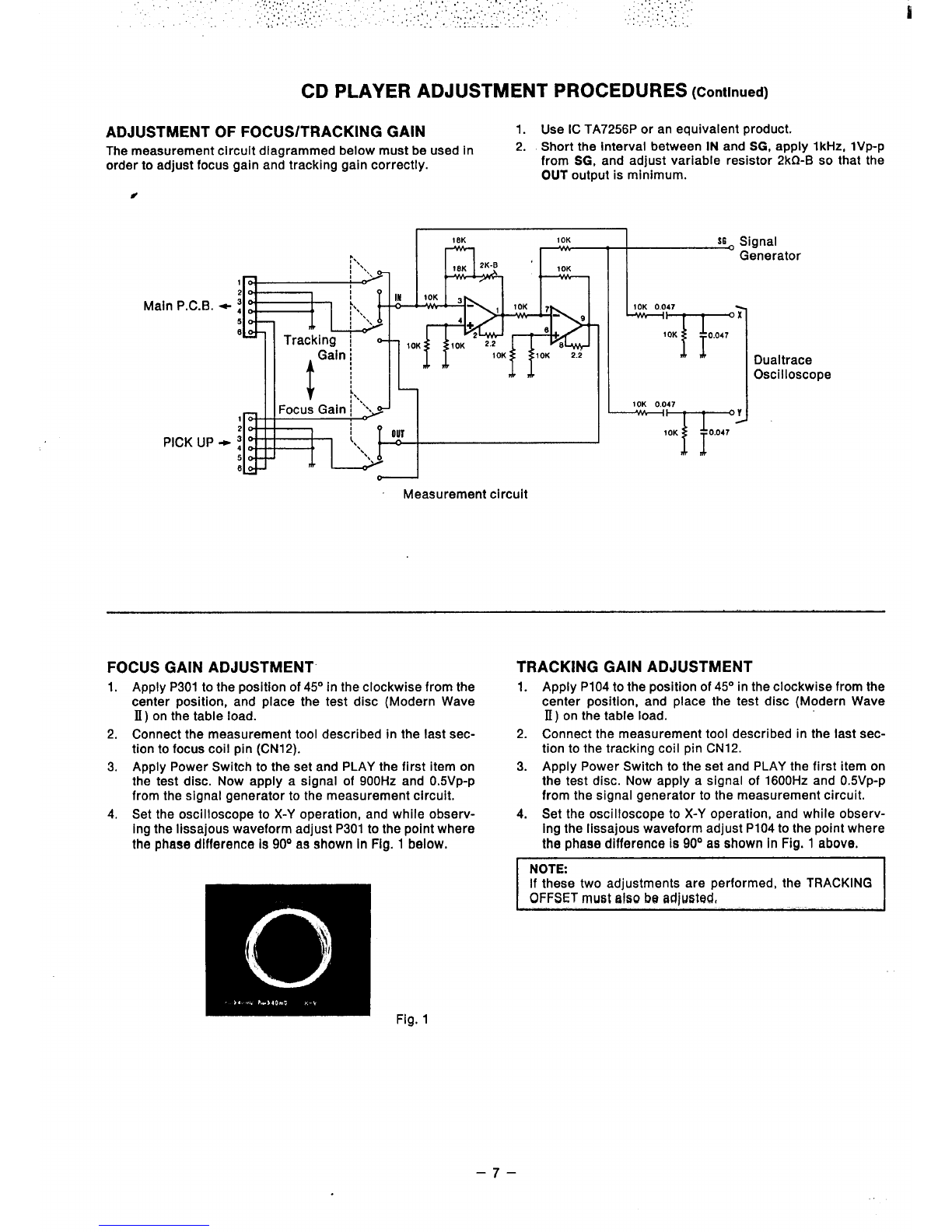

Adjustment of Focus/Tracking Gain ., .,.... . . . . . . . . . . . . . . . . .,0 .....0..,.... . . . . . . . . . . .

Focus Gain Adjustment ... .,,.,, ., .0,.,,, ., .,,,.,, ., . . ...0. 0.,..,... . . . . . . . . . . . . . . . .

Tracking Gain Adjustment . ...,,,.,. , ...4,..., ,...,,,,0, 0.?, .,,,4, ,, .,,,.,,. . . . . . . . .

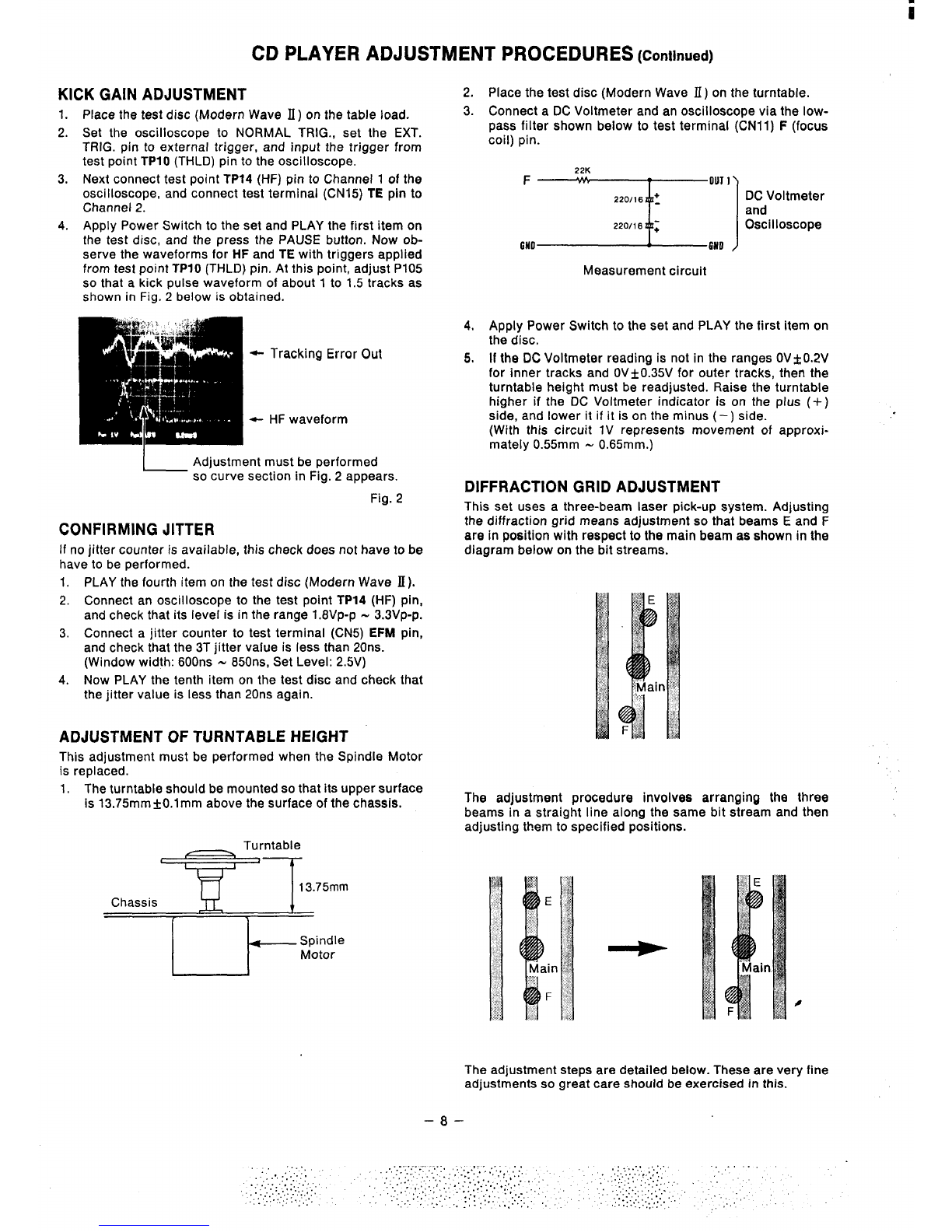

Kick Gain Adjustment ,, .,...0,. .00.,0..,. ,, .,,,,,,. , ..,.,,,.. ,,, ,,4, ,,, ,, ...4..... .

Confirming Jitter . . . . . . . . . . . . . . . . . . . . . . . . . . . ,. .,,.,,, . . . . . . . . . .. 0.,..,, .,, . .. s., 0..

Adjustment of Turntabie Height ., ,0,..., .. 0...0., . . . . . . . . . .,, ,, .,,. $. .......,. .,,,.0.

Diffraction Grid Adjustment ,. ..,... ,., ,. .,. . . . . . . . . . . . . . . . . . . . . . . . . . ..!.... .........

Diffraction Grid Adjustment .....................................................0.. .

3

4

4

4

4

5

5

6

6

6

6

6

6

6

6

6

7

7

7’

8

8

8

8

9

ii

..

,, l!.,~

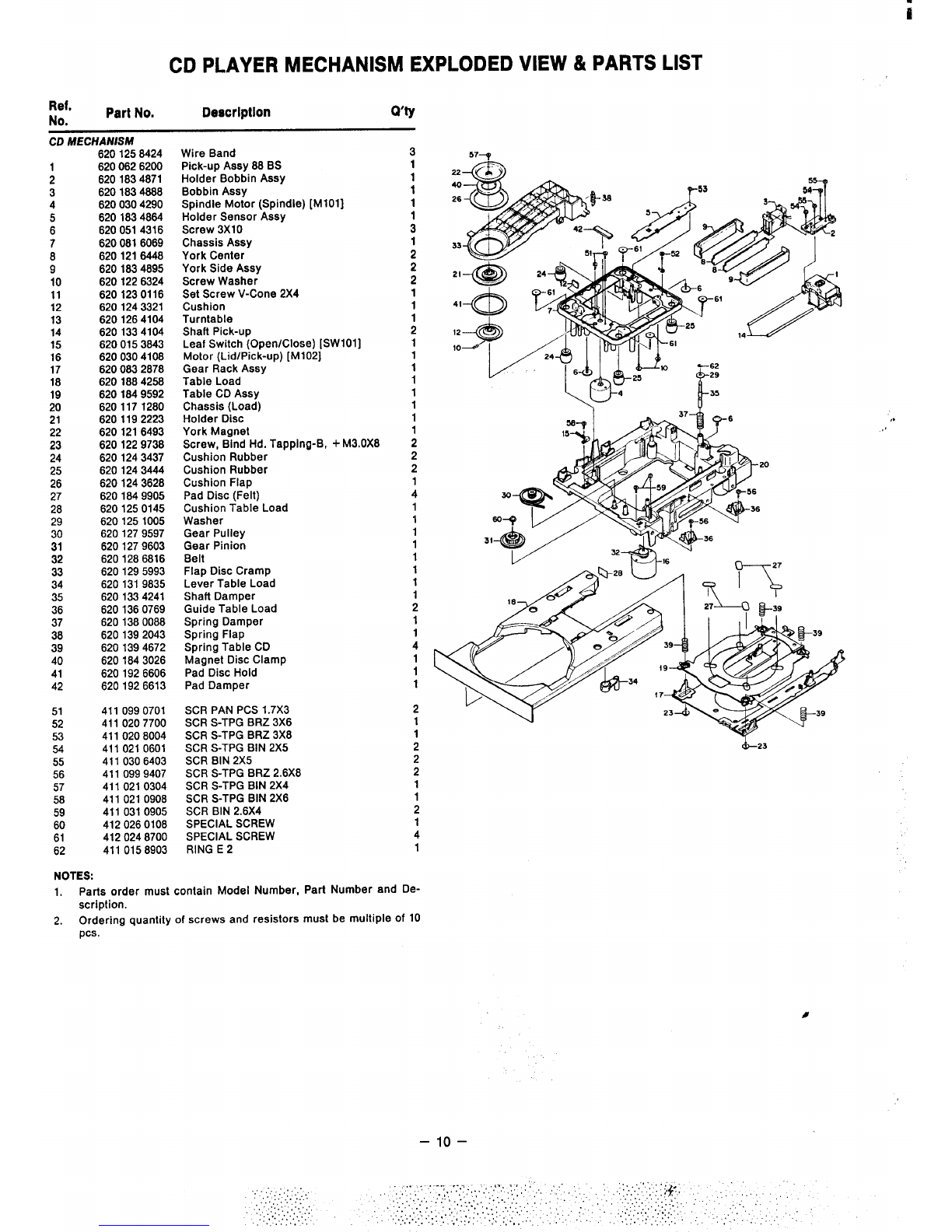

CD Player Mechanism Exploded View& Parts List ....0..,. . . . . . . . . . . . . . . . . . . .,, ,, .,.. ,.. .#. 10

Block Diagram (Main Unit Section) ................... ...0. ,, .0.... ...................... 11

System Block Diagram (Function Section) ... . . . . . ,, ..,,.. . . . . . . . . .. 0.0... 0,.,,00. .! 0.0... 12

M-COM (LC6554H)System Biock Diagram ., ..,..0. .0 .,.0.., . . .. s.,., ....................0 13

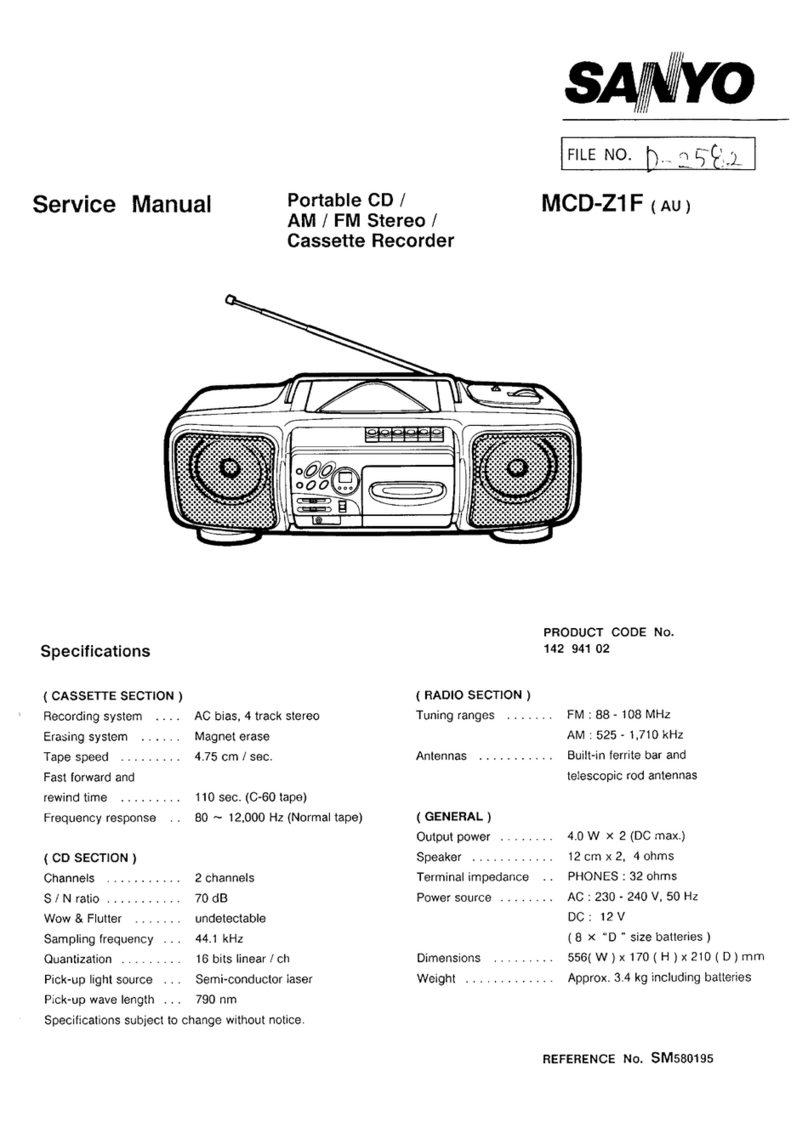

Caution on RFAdjustment . . . . . . . . . . . . . . . . . . . . ,, ..,,,.., . . . ...0... .....................14

System Ciock Adjustment ., .,,,,,, . . . . . . . . . ,,, .,,.., ,. .,..,,0 .........., .,,,,,0 Os0,... 14

FM Tuner Ailgnment ....................................... ,0.,.. ,, ..,..00 ...........14

AM Tuner Alignment . . . . . . . . . . . . . . . . . . . ..,, ,. .,,,,, .,, ..,,.,, s,, ,,, ...................15

Cassette Deck Eiectricai Adjustment . . . . . . . . . O* .,...,. ,. .,,..,, ., .,,,.,, ., .,.,,., 0,, ..,.. 16

Before Adjustment ................................................................16

Measuring instruments Required ,, ...,.. .............................................16

Switch Positions . . . . . . . . . . . . . . . . ,,, .,.., . . . . . . . . . . . . . . . . ,, .,..,. . . . . . . . . . . . . . . . . ,. 16

Normai Tape Speed Adjustment ,., ,,, ,. . . . . . . . . . . . . . . . . ,. ..,.,0 .,, .,0.. . . . . . . . . .0 .,.. 16

High Speed Tape Speed Adjustment ,., ,, .,.. ,, .0,..,. .,, ,,, ... ... ,,, ,., . . . . . . . . . . . . . .

Head Azimuth Adjustment . . . . . . . . . . . ... ..,..0 . . . . . . . . . ,., .,,.,. ., .,0..,, ..........0 ;:

Piayback Sensitivity Adjustment ............................,., ,. .0.. .................17

FL Meter Sensitivity Adjustment ,,, ..,,,, ,, ..,,.,, . . . . . . . . . ,,, ,, . . . . ... .*,,.. .........17 ..,, ‘:,

Recording Bias Level Adjustment (Deck2) .,,

......................,..0. ................0. .17 ‘“-””-’’””’i’

Cabinet Exploded View &Parts List 18 “,.

,0,,...00 .0, .,...0 .,0 ...,.... . . . . . . . . . 0. . . .. $0. .0 . . ...0

Cassette Deck Mechanism Expioded View &Parts List ‘I

. . ...0... .,, ,., ..,. . . ...0... ............21

P.C.Board Parts List ,,.

.,

. . . . . . . . ... ,., ,. 0...,... . . . . . . . . . ...0... . . ...0.. . ........ ....... ..23

P.C.Board Parts List ,,

,. .,,.,. . . . . . . . . ,, .,,,., ,. .0.... ... ...0, ,. ..0..0 ......0. . ....... ..28

Wiring Diagram (CD Piayer Section) . .,,.,,,,, .......... ,0 .,,..... . .,,0,,,,, ,,, .00...,0 . . 51

Wiring Diagram (Power Main Section) . . . . . . . . . . . . . . . . . . . . . . . . ,. .,..,, . . . . . . . . ,,, ..,., ,,, 52

Wiring Diagram (Main Unit Section) ....................................0... .............53

Schematic Diagram (Tuner Section) ......................................................55

Schematic Diagram (Deck/Function/Front Controi Section) ...................................57

Schematic Diagram (Deck/Function Section) ...................0 ..,,.,. . . . . ...0. ...... ....59

Schematic Diagram (CD Piayer Section) . . . ... . . . 0...0...’. .. ’0....., ....... ....... ........ .61

Schematic Diagram (Main Power Section) .:

..................0,, .,,.,, . . . . . . . . . ,,, ,. .,... . . 63 0

iC Block Diagram ,., ,, .,. ,,, ,,, ,! ,,, ,,, !* ,,,~~,f, ,,tt f,,,, :,~~t,,~ ,,, ,,, ,, ,,, ,. .,. ,,, , 64

IC &Transistor Lead Identltlcat{ori ,.,4,,,.,., . . . . . . . . . . 0. .,,,,..., 4. . ...*.... C** S* .4.**. .79

1,

–2–