−

3

−

● Precautions

1. Handling batteries (for battery-operated model (quartz type) only)

・ At loading batteries, use two C size batteries and confirm that the polarities

(+/−) are correct.

・ Replace the batteries to new ones every year. Be sure to replace all two

batteries with new ones of the same type.

・ Do not get the batteries charged.

・ Do not dispose of used batteries in a fire.

・ For environmental protection, dispose of used batteries in compliance with local

rules and regulations.

NB : When the liquid leaks, immediately wipe or wash out the liguid.

2. Replacement of cartridge pen

・ Pull pen lifting lever toward you until it stops.

・ To remove the cartridge pen, pull toward the direction of the arrow.

・ To attach the pen, slide it onto the pen arm until it stops.

・ Don’t touch pen tip. If the finger grease adhere, ink

will not flow smoothly.

・ Cartridge pen will last about six months (in use of 7

day chart), but life may be shortened by the

conditions of use.

NB : Be sure to use our dedicated cartridge pens.

3. Attaching chart

Make sure the markings on the chart are aligned where the overlap occurs, and

the lower edge of the chart is against the bottom lip of the cylinder.

NB : Be sure to use our dedicated charts.

4. Carrying instrument

Before lifting the instrument with the handle, make sure that it is locked.

● Installation place

Do not use in the followings. Use in such environments may causes of error in

indication and record.

・ In a place with vibration, shock or inclination.

・ Outdoor use (exception in a instrument screen)

・ At exhaust port of airconditioner or at a place subject to direct sunlight.

・ In dusty of sooty environments.

・ Use of blocking the ventholes of the acrylic cover.

・ Near splashing water.

・ In corrosive gases.

● Other precautions

・ Use the instrument within the measuring range.

・ Be sure to remove the packing materials that hold the mechanical parts

attached at shipment.

・ Do not cover the instrument with a vinyl or like for waterproof purpose or etc. If

so, correct value will not be obtained.

・ Don’t disassemble the instrument. Doing so may result in failure.

・ Remove the batteries during transportation.

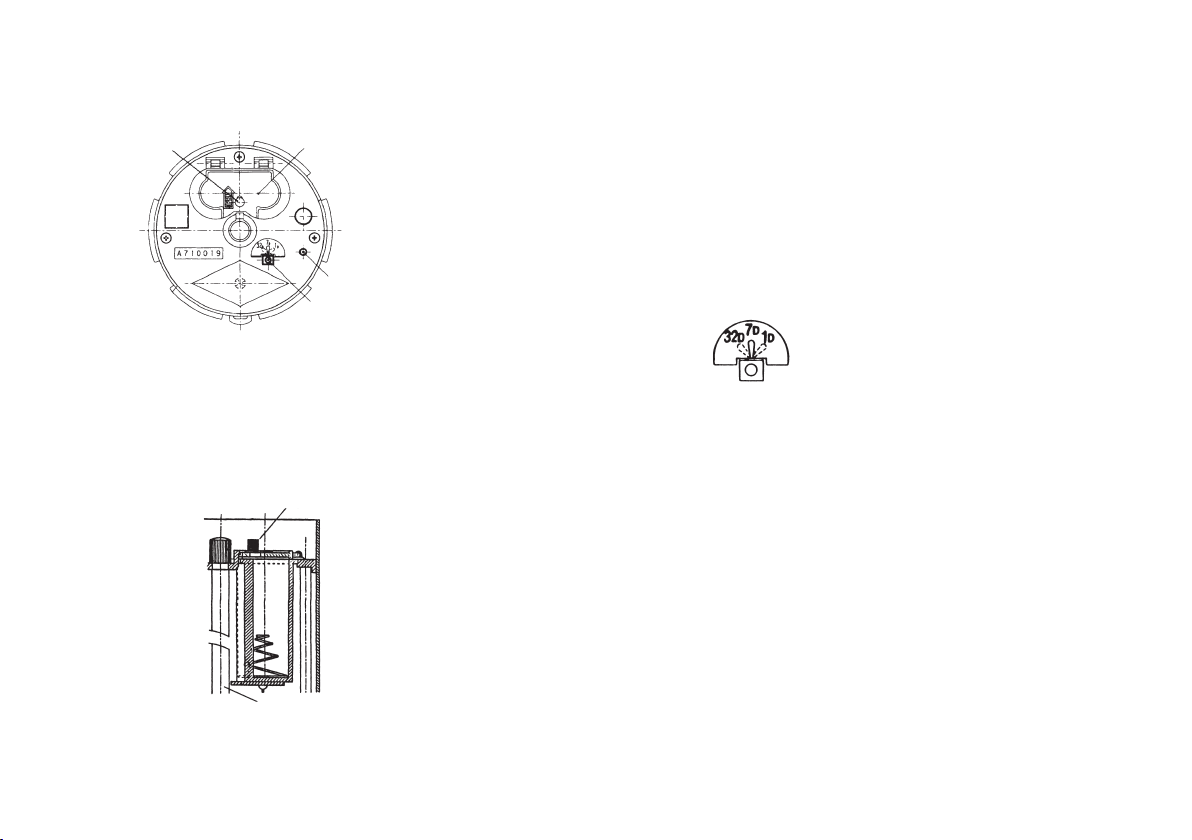

● Indication adjustment

Fine adjustment is available, however please avoid using except when necessary

as the instrument is calibrated at our factory. If some adjustment is required,

follow these procedures:

To increase indicated readings, turn the fine adjustment screw counterclockwise.

To lower the indicated readings, turn the fine adjustment screw clockwise. (Figs A-

1 and A-2) Fine adjustable range (Temperature: ±3℃. Humidity: ±5%)

It is desirable to calibrate the instrument periodically once a year.

Fine adjustment-temperature Fine adjustment-humidity

A-1 A-2

−

4

−

For battery-operated model (Quartz type)

●Recording cylinder

● Loading batteries

・

To open the lid of the battery compartment, pull the knob outside.

・

Insert two C size batteries into the battery compartment with the correct

polarities (+/−).

・

Close the lid while pulling the knob outside.

●Verifying operation

Cylinder starts rotating soon after the batteries are installed. Confirm that LED

(green) is blinking.

Knob

●Checking battery condition with LED

LED (green) goes out when the voltage of the battery becomes 2.2VDC ±10% or

less under normal ambient. At this time, replace the batteries to the new ones

immediately.

NB : Recording cylinder stops operation in approx. one month after the LED

goes out under normal ambient.

●Changing cylinder speed

The cylinder speed switch is set for 7-day

operation at factory shipment.

Set the switch at the top of cylinder to 1D or

32D for 1-day or 32-day operation. (Fig. 2)

NB: Be sure to replace the chart according

to its recording period.

Fig. 1

Battery

compartment

Knob

LED (Green)

Cylinder speed switch

Fig. 2 Cylinder speed switch