SaturnEquipmentLimitedWarranty

SaturnTM EquipmentLimitedWarranty

Saturn warrants itsnew productto be freefromdefectsin

materialandworkmanshipfora period ofone(1)year from

the originaldate of installationnot toexceed 18monthsfrom

dateoforiginalshipment from factory. Equipmentsoldand

installedforresidential use, or outside the continental United

States is excluded from warranty. Thiswarrantyislimitedto

product(s) soldtotheoriginal commercial user. Theliability of

Saturn islimitedto, atSaturn option the repairor replacemen

ofany partfound bySaturntobe warranted herein.

Saturn shall bear thenormallaborchargesforrepairor

replacement totheextentthat such repair or replacement

is performedwithin35 miles oftheofficeof an authorized

service agency,within the

continental UnitedStates and dur-

ing regular (straighttime) hours.Travel outside of the35miles

andany workperformed atovertime or weekend rates isthe

responsibilityof the owner/user. Defective partsmust be

returnedto Saturn, freightprepaid,fo

Saturnassumesnoresponsibilityforany product(s) notin

stalled properlyin accordancewith theinstructions supplied

with theequipment. Any equipmentwhich hasbeenmodi

fied byunauthorized personnelorchangedfrom our origina

designis not coveredunder this Warranty.

Saturnassumesnoobligation foranyproductwhichhasbeen

subjecttomisuse, abuseorharsh chemicals. Normalmainte

nanceasoutlinedin theinstructionssuppliedwiththeequip

ment istheresponsibility of

theowner-userandisnot part of

Light bulbs, porcelain,glass components, normal parts,wear

andmaintenanceareexcluded fromthiswarranty.

Saturn Fryerscarry oneyearpartsandlaborwarranty anda

limited, prorated 5 year warranty on

stainless steelfryvessels.

Thiswarranty is inlieuof any other agreement, expressed

or implied, andconstitutesthe onlywarranty of Saturn

with respectto the product(s).

Saturnshall not beliablewhetherincontractor intort or

underanyother legal theory,for lossof revenueorprofit,

or anysubstitute useor performance,orfor incidental, in-

direct,special orconsequential damages,or foranyother

lossor cost of similar type.

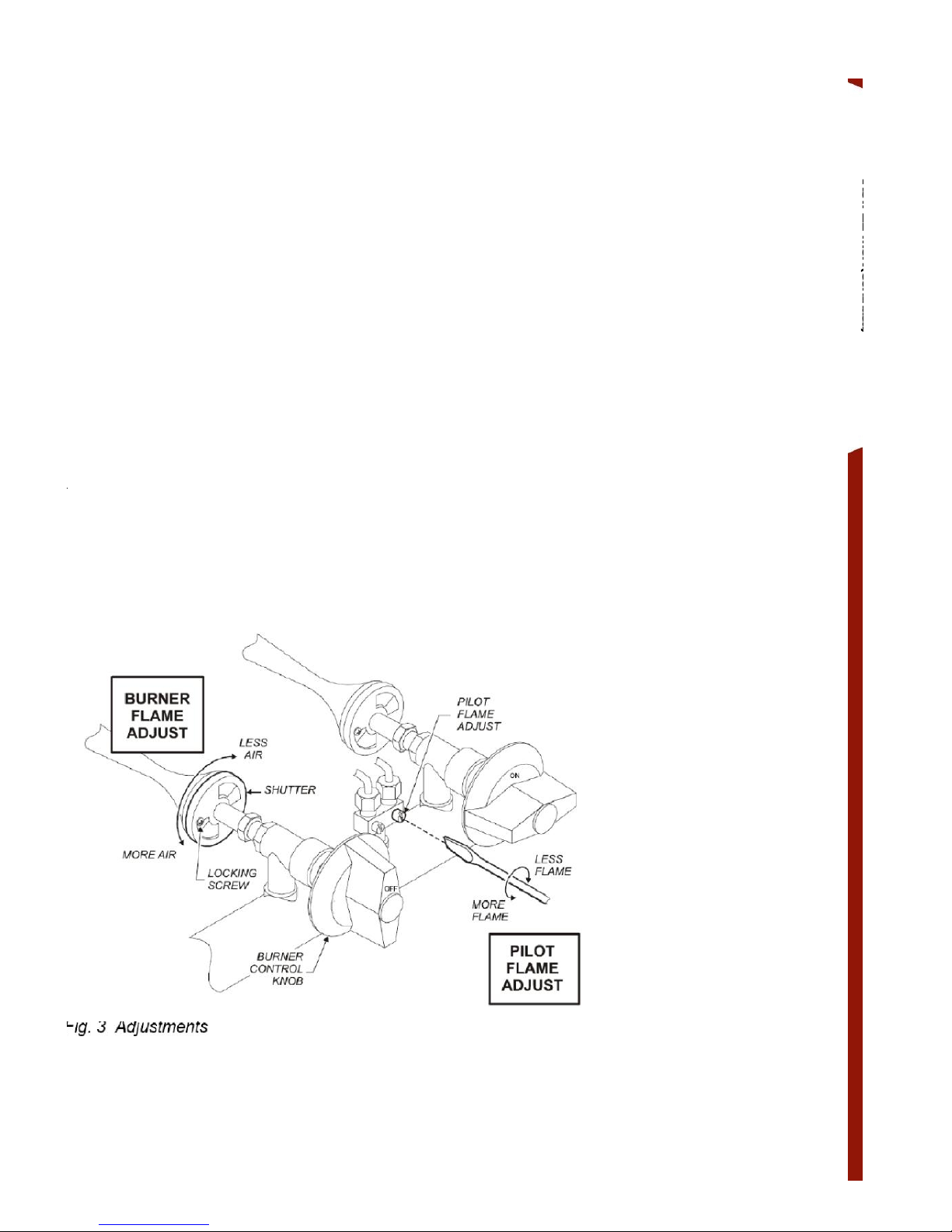

Proper installation,initial checkout, air shutteradjust-

ments,or normal maintenance such aslubrication, adjust-

ment orcalibration of controlsis theresponsibilityof

thedealer,owner-user orinstalling contractorandisnot

covered bythiswarranty.

TheCompany reservestheright,without priornotice,to

makechangesandrevisionsinthe productspecifications,

design, andmaterial.

Possessionofthis pricelist does not constitute an agree-

ment oroffertosell product to the possessor.

Prices aresubjecttochangewithout notice. Pricesdo not

include salestax.All pricesare in U.S. dollars.

Returnedgoods are subjectto a 20%restockingcharge

and thecostofreconditioningtheequipment for resale.

Prior toreturningthe goods, aReturnGoods Autho-

rization(RGA) number mustbe granted bySaturn. All

returned goodsmustbe shippedfreight prepaid. Ship-

mentsreceived withoutaRGAnumberwill be refused.

Customunitsbuilt to thebuyersspecificationsmay not

bereturnedorcancelled.

Saturn isnot responsibleforprinting errorsin pricingor

specification.

SERVICEPOLICY ANDPROCEDURE GUIDEand ADDITIONALWARRANTY EXCLUSIONS

Resetting ofsafetythermostats, circuitbreakers,

load protectors, and/or fusereplacementsare not

coveredbythiswarranty unlesswarrantedconditions

Allproblems due tooperationat voltagesor

otherthan specifiedonequipment nameplates

not covered by this warranty.

on to correct voltageand/or phasemustbe

the customers responsibility.

Allproblems due to electricalconnectionsnot

in accordancewithelectricalcode requirements

and wiringdiagramssupplied with the equipment are

not covered by this warranty.

Replacement ofitems subjectto normalwear,

include such itemsasknobs, light bulbs;and,normal

maintenancefunctions including adjustments of

thermostats, adjustmentof micro switchesand

replacementof fusesandindicatinglightsare not

Damagetoelectrical cords and/orplug dueto

to excessiveheatarenot coveredby this

Full use, care,and maintenanceinstructions

witheach machine. Notedmaintenanceand

preventativemaintenanceitems,such as

servicingand

cleaningschedules,are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility.Proper attention topreventative

maintenanceand scheduled maintenanceprocedures

willprolong thelifeof theappliance Travel mileageis

limited tosixty(60) milesfrom anAuthorizedService

Agency oroneof itssub-serviceagencies.

7. All laborshall beperformedduringregularworking

hours. Overtime premium willbe chargedtothebuyer.

8. All replacement parts are warrantedfor

ninety(90)days fromdate of purchaseon non warranty

equipment.Thispartswarrantyislimitedonly

to replacementof thedefectivepart(s).

9. Installation, labor, and job check-outsarenot

considered warrantyand are thusnotcoveredbythis

warranty.

10.Chargesincurred by delays, waiting timeoroperating

restrictions that hindertheservice technicians ability to

perform service are notcoveredbywarranty. This

includes institutional and correctional facilities.