8 www.saunacore.com

STEAMCORE

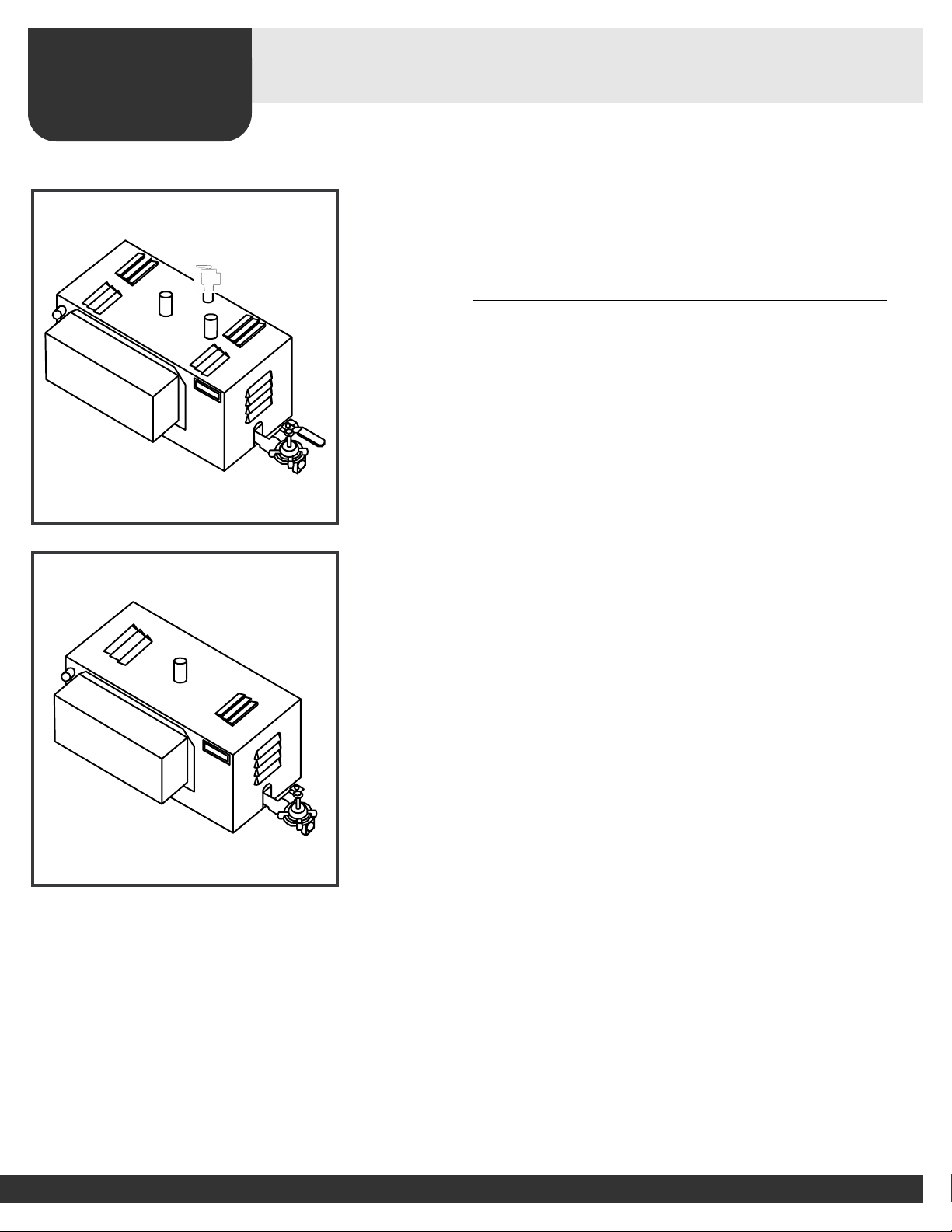

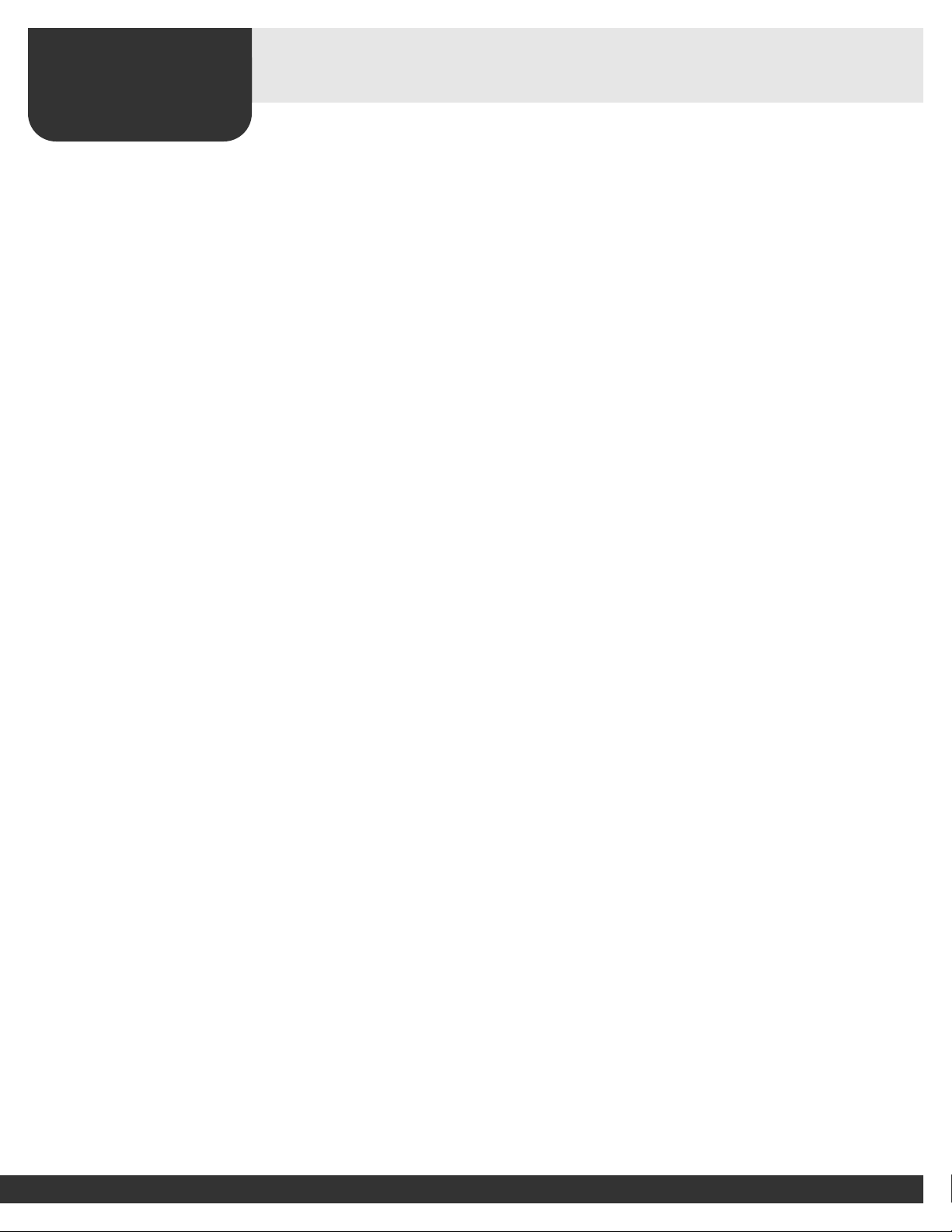

Steam Connections:

A ½ inch union fitting is supplied at the single steam outlet on KWS 2, KWS

3, KWS 4.5, KWS 7.5 model generators that will use one steam head. A 1

inch union fitting is supplied at the steam outlet on all KWS 9 to KWS 36

model generators. All 1 inch steam outlets on the unit must be reduced to

two ½ inch lines using a T reducer before reaching the steam room and the

½ inch pipe length to be close to equal lengths to the steam room. Each 1

inch steam line on your unit will require two standard steam heads or one

designer steam head. (Depending on the model, your steam generator may

have up to 4 - - 1 inch steam outlets on the unit that will be reduced to 8 ½

inch steam lines to the steam room, using 8 standard steam heads or 4

designer steam heads). Do not have any low points in the line that will allow

condensation to sit in the steam line(s). The steam heads should be

mounted approximatly 10 to 12 inches above the floor and 6” away from a

corner, located in an area where you will easily avoid physical contact.

Direct the steam head(s) outlet slot down and the fragrance reservoir up. If

steam room is provided or built with seat(s), locate steam head as far away

from seat as possible.

Drain:

This is a gravity draining system on all model steam bath generators. A ½

inch compression fitting is supplied with the unit and is to be installed on a

½ inch copper pipe that slopes slightly downwards and away from the unit.

It can be plumbed into an existing drain line or to an open floor drain. If

there is absolutely no drain available, you may direct it into the shower/

steam room. When connecting, you must use the two wrench method or

you may break the seal on the connection between the drain pipe and the

boiler tank, and cause leakage.

Testing: Now that your Steamcore is connected, you must test it.

1. Turn on your water supply and check for leaks.

2. Turn on your power supply at the electrical panel; be sure the unit is

receiving power.

3. Set the 30 minute mechanical timer to the desired time and wait for

steam.

Option: Elegance Controls - - set temperature and press on

Option: Press Air Switch until red LED Light comes on and

wait (pre-programmed 30 minute timer and temperature set at 50

degrees Celsius)

4. Within a few minutes your steam room should begin to fill with steam.

5. Check to make sure your steam lines do not leak condensation and steam.

6. You may want to insulate the steam lines with pipe insulation; this is

strongly recommended if your steam generator is more than 10 feet from

the steam room.

General Installation Instructions (All Steam Bath Units)

NOTE:

To preserve steam head finish, do not use wrench

or other tools to tighten. Hand tightening is

sufficient when Teflon or equal pipe thread

sealing compound is used.

NOTE:

A drain valve is provided to facilitate servicing.

Where local codes permit, provide a drain line

connection from a generator drain valve. Check

local plumbing code for receptor, trap and vent

requirement. Unit drains by gravity. Slope down.

CAUTION !!

The steam head(s) (or nozzle(s)) create very

high degree of temperature in and around the

steam heads during use. The steam heads

should be installed as far away from any bathers

path. Bathers are to avoid this area and from any

direct contact to the steam heads. Burn or injury

may occur if touched or in the vicinity during use.

Appropriate protection should be provided to

avoid injury.