TABLE OF CONTENTS

Assembly Options................................................................................

Before You Begin..................................................................................

Product Specications.........................................................................

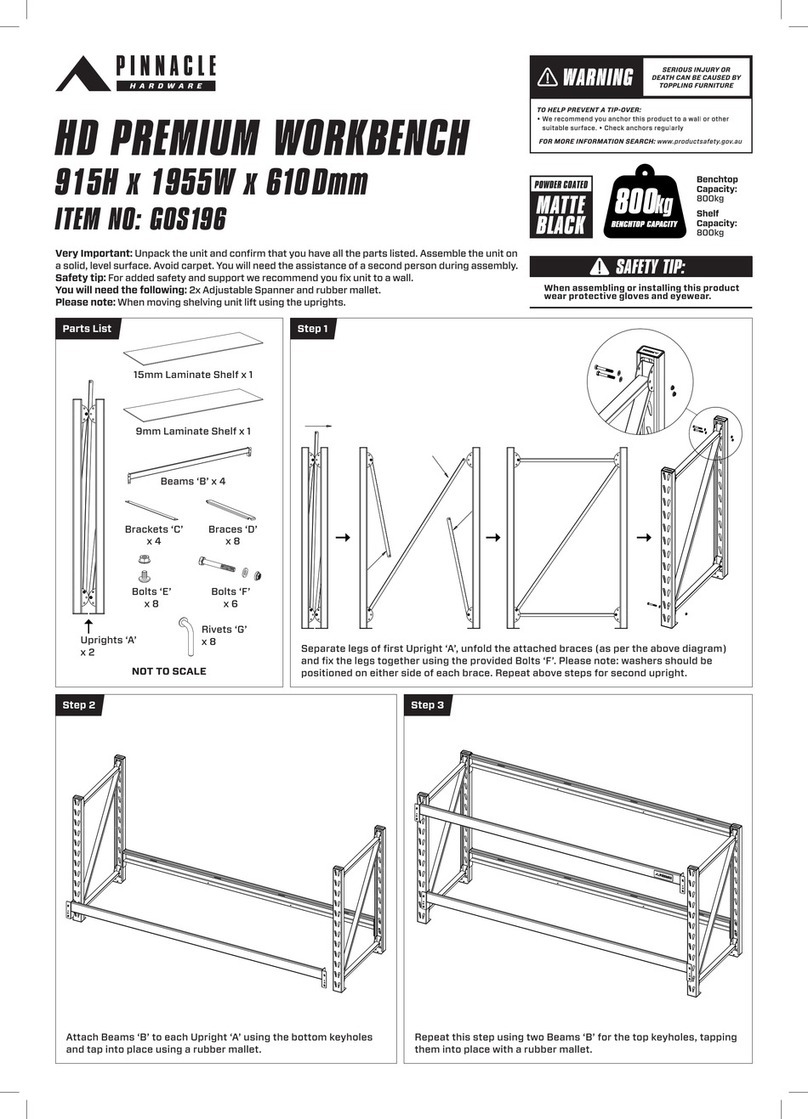

Parts Inventory.....................................................................................

Cast Iron Table Parts and Hardware.............................................................................

Support Legs Parts and Hardware...............................................................................

Power Switch Parts and Hardware................................................................................

Fence Assembly Parts and Hardware............................................................................

Assembly & Installation........................................................................

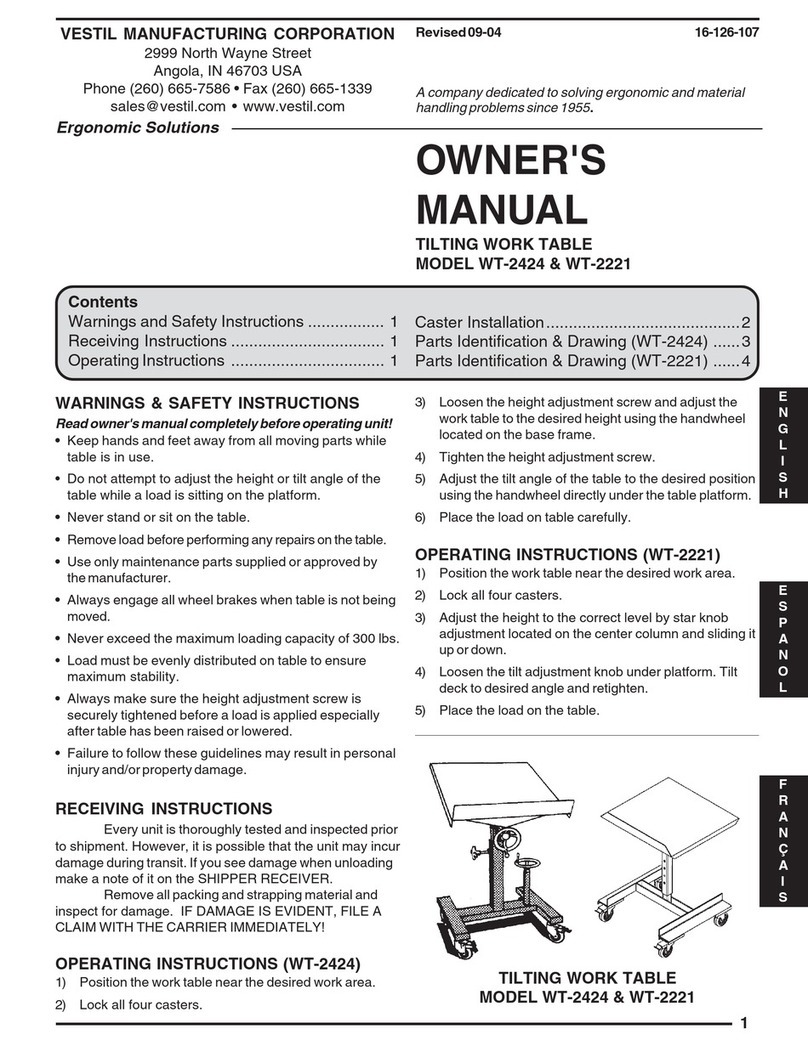

Assembling the Cast Iron Table......................................................................................

Hold-Down Strap Installation........................................................................................

Assembling and Installing the Support Legs and Power Switch...................................

In-Line Installation Left of Left Wing..............................................................................

Rail Requirements: In-Line Right of ICS Right Wing.....................................................

In-Line Installation Right: Between 36” Rails.................................................................

In-Line Installation Right: Between 52” Rails.................................................................

Assembling the Fence Assembly...................................................................................

Reference............................................................................................

Warranty.........................................................................................................................

Safety.............................................................................................................................

Warnings........................................................................................................................

Exploded View 1: Cast Iron Table (RT-C30) ....................................................................

Parts List 1: Cast Iron Table (RT-C30).............................................................................

Exploded View 2: Support Legs (RT-ST2).....................................................................

Parts List 2: Support Legs (RT-ST2)................................................................................

Exploded View 3: Power Switch (RT-PSW)..................................................................

Parts List 3: Power Switch (RT-PSW)...........................................................................

Exploded View 4: 32” Fence Assembly (RT-F32)...........................................................

Parts List 4: 32” Fence Assembly (RT-F32)....................................................................

Available Accessories..........................................................................

1

4

5

6

6

7

8

9

11

11

12

16

20

22

23

25

31

36

36

37

37

39

40

41

42

43

44

45

46

47