2

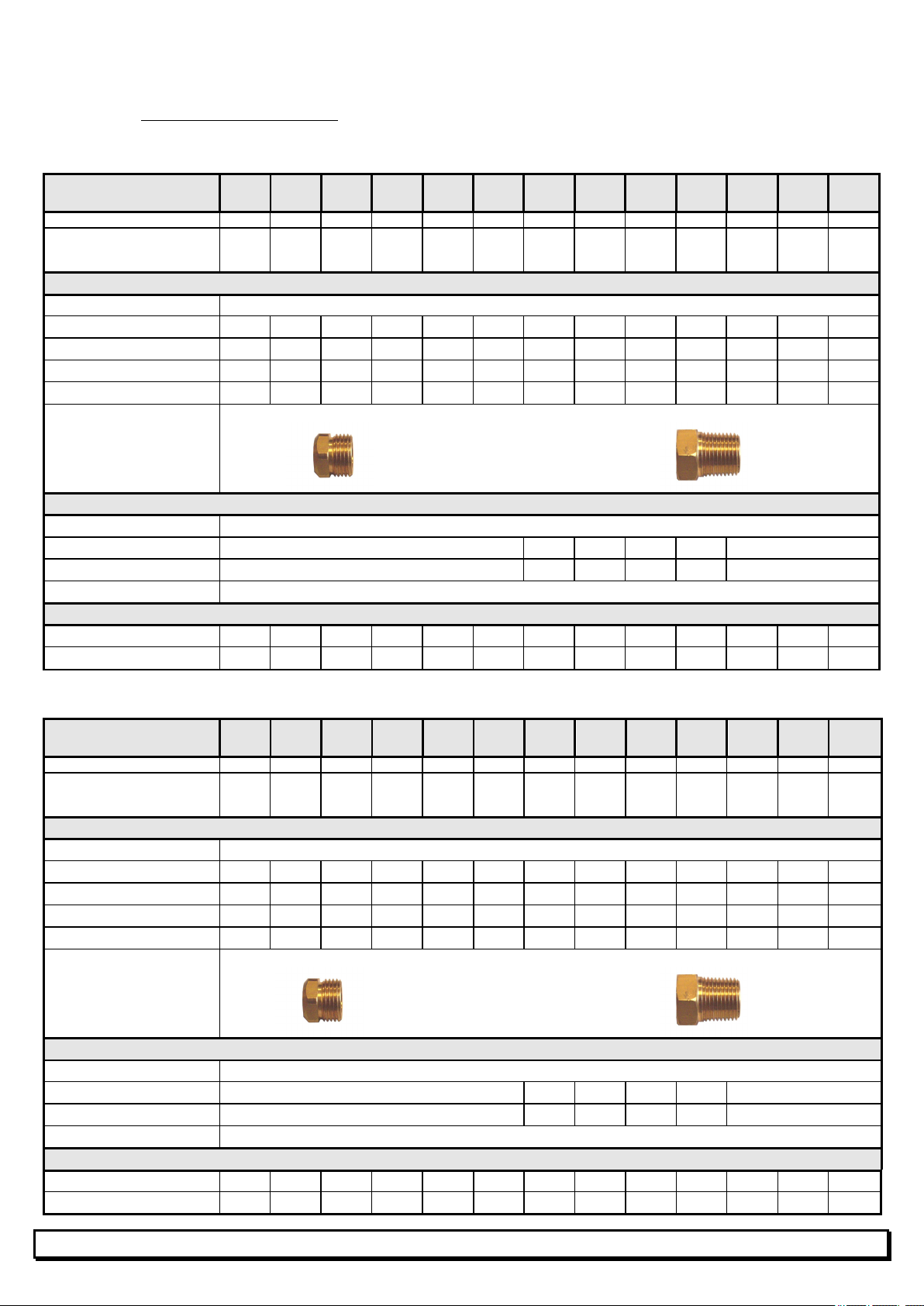

1. PRODUCT SPECIFICATION

1.1 Technical specifications :

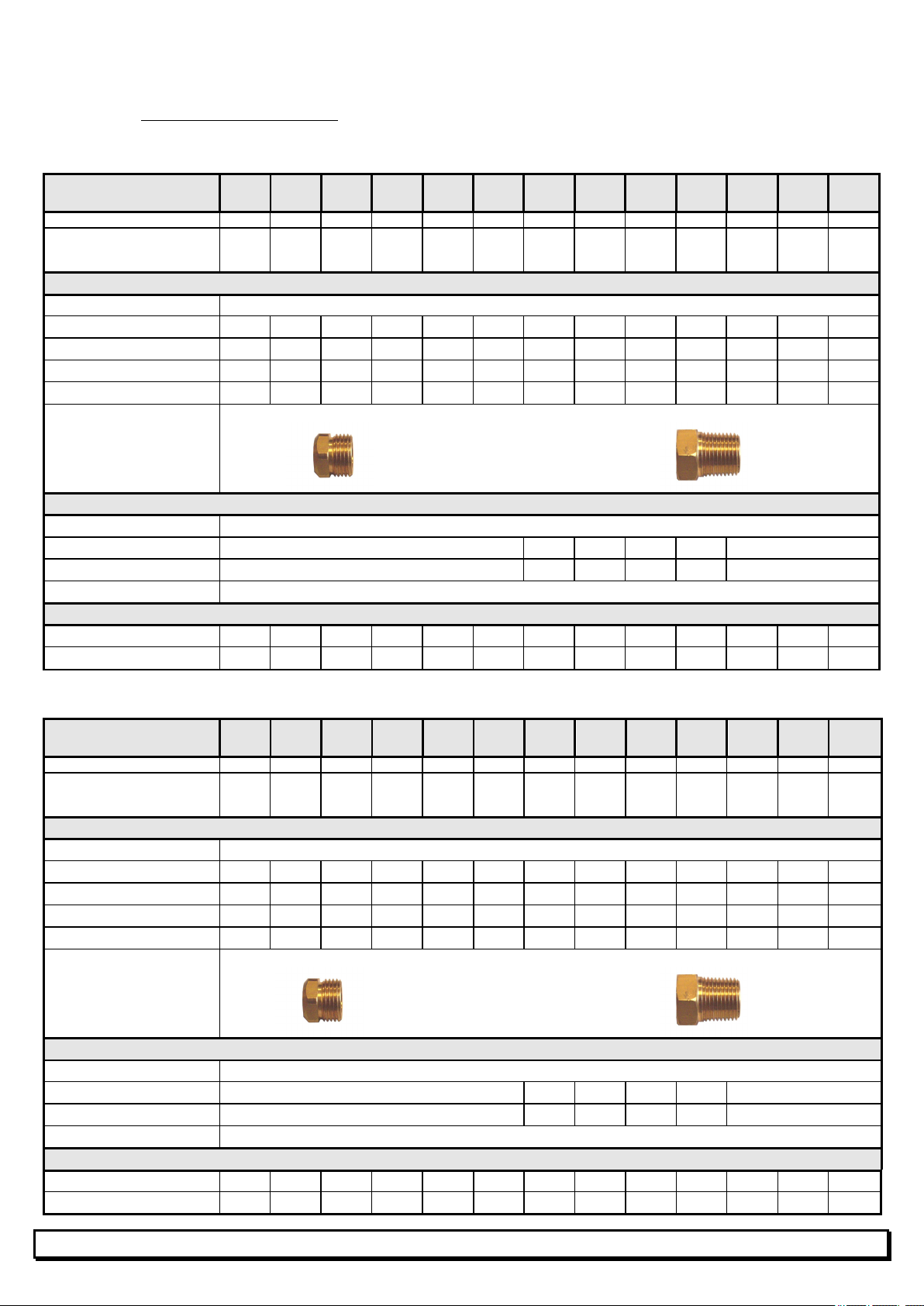

GAS : G20 (Natural gas) - Category : I2Esi

MODEL

SX

SX

SX

SX

SX

SX

2SX

SX

2SX

SX

2SX

2SX

2SX

Weight (kg) 2.5 2.9 3.1 3.4 4.1 5.0 5.0 5.5 5.5 6.7 6.7 9.4 12.2

Net calorific value

Qn (kW) Hi 2.50 3.30 3.80 5.10 6.75 7.60 7.60 10.20 10.20 13.50 13.50 20.25 27.00

GAS

Inlet pressure 20 mbar

Injection pressure (mbar) 13.0 11.0 12.0 15.0 16.7 12.0 12.0 15.0 15.0 16.7 16.7 (See B)

16.7

Gas consumption (m3/h) 0.265 0.350 0.400 0.540 0.715 0.805 0.805 1.080 1.080 1.430 1.430 2.145 2.860

Ø prim. Inject. (1/100 mm) 170 180 195 240 320 260 2x195 380 2x240 - 2x320 (See A)

-

Ø sec. Inject. (1/100 mm) 135 165 170 180 195 2x170 2x170 2x180 2x180 2x195 2x195 (See A)

4x195

Gas input connection

Fitting G1/2" cylindrical (ISO 228-1) or Tapered fitting R1/2" conical (ISO 7-1)

ELECTRICITY

Power supply 230V (+10% -15%) - 50Hz Neutral mandatory

Consumption 0.1A 2x0.1A

0.1A 2x0.1A

0.1A 2x0.1A

Individual fuse 0.25A 2x0.25A

0.25A 2x0.25A

0.25A 2x0.25A

Ignition cycle length 45 seconds

VENTILATION

Combustion air (m3/h) 2.60 3.40 3.90 5.30 7.00 7.90 7.90 10.50 10.50 13.90 13.90 21.00 27.80

Req. air change (m3/h) 25 33 38 51 67.5 76 76 102 102 135 135 202.5 270

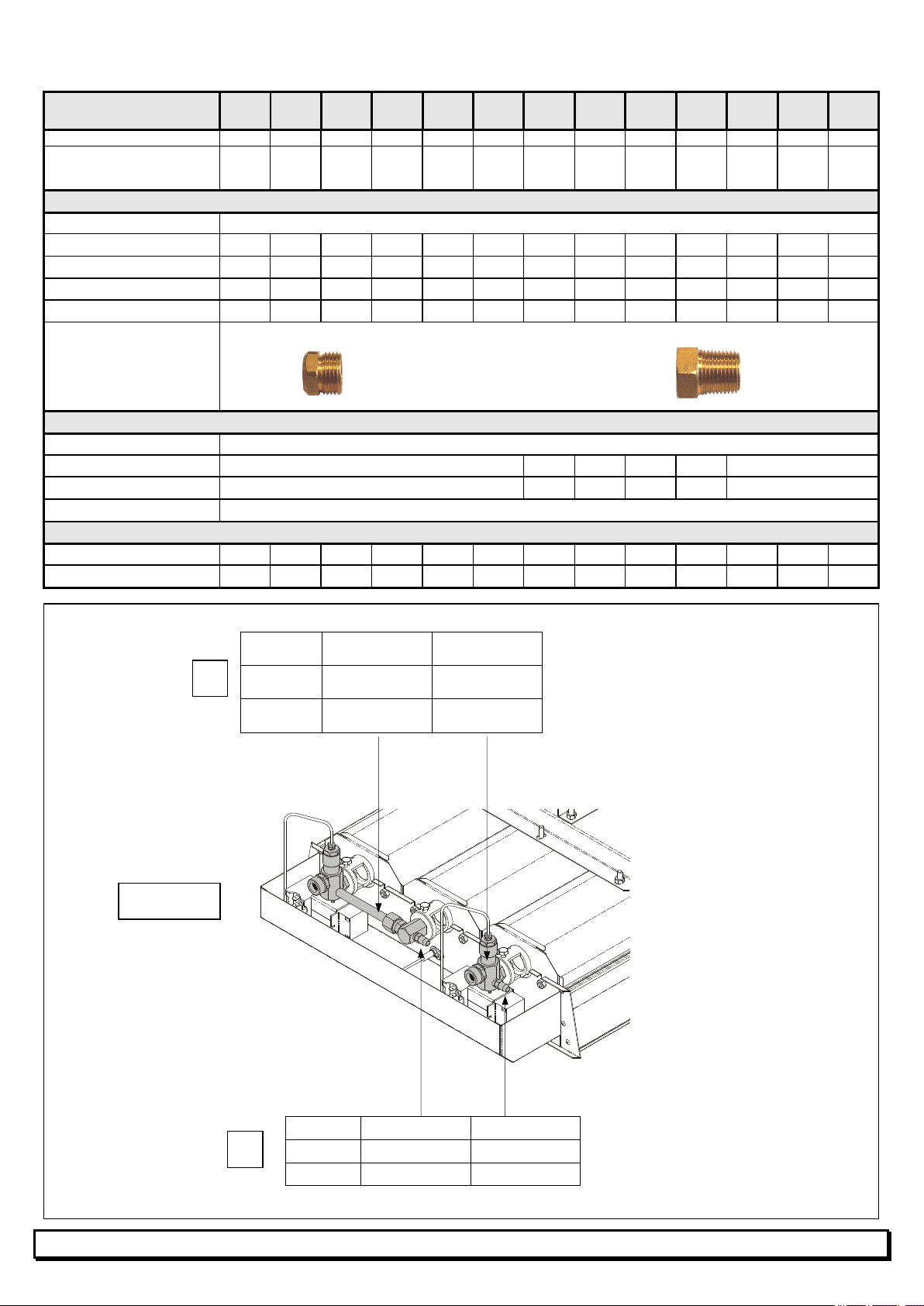

GAZ : G31 (Propane) - Category : I3P

MODEL

SX

SX

SX

SX

SX

SX

2SX

SX

2SX

SX

2SX

2SX

2SX

Weight (kg) 2.5 2.9 3.1 3.4 4.1 5.0 5.0 5.5 5.5 6.7 6.7 9.4 12.2

Net calorific value

Qn (kW) Hi 2.50 3.30 3.80 5.10 6.75 7.60 7.60 10.20 10.20 13.50 13.50 20.25 27.00

GAS

Inlet pressure 37 mbar

Injection pressure (mbar) 34.0 21.0 21.0 28.0 37.0 21.0 21.0 27.5 28.0 34.0 37.0 (See B)

34.0

Gas consumption (kg/h) 0.195 0.260 0.300 0.400 0.530 0.595 0.595 0.800 0.800 1.055 1.055 1.590 2.110

Ø prim. Inject. (1/100 mm) 155 140 130 180 - 185 2x130 240 2x180 370 - (See A)

2x370

Ø sec. Inject. (1/100 mm) 82 105 110 125 135 2x110 2x110 2x125 2x125 2x135 2x135 (See A)

4x135

Gas input connection

Fitting G1/2" cylindrical (ISO 228-1) or Tapered fitting R1/2" conical (ISO 7-1)

ELECTRICITY

Power supply 230V (+10% -15%) - 50Hz Neutral mandatory

Consumption 0.1A 2x0.1A

0.1A 2x0.1A

0.1A 2x0.1A

Individual fuse 0.25A 2x0.25A

0.25A 2x0.25A

0.25A 2x0.25A

Ignition cycle length 45 seconds

VENTILATION

Combustion air (m3/h) 2.30 3.10 3.60 4.80 6.30 7.10 7.10 9.60 9.60 12.60 12.60 18.90 25.20

Req. air change (m3/h) 25 33 38 51 67.5 76 76 102 102 135 135 202.5 270