4

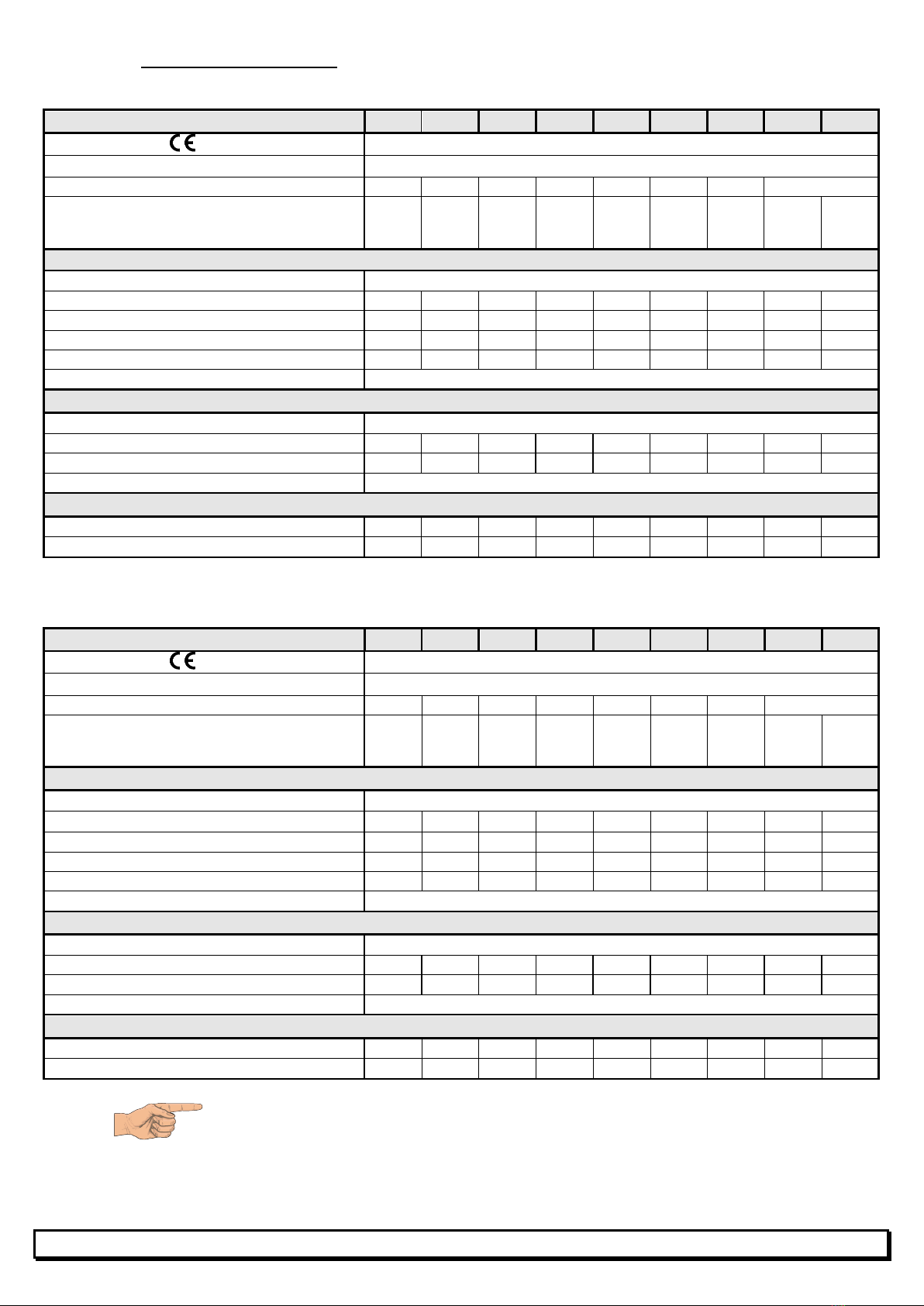

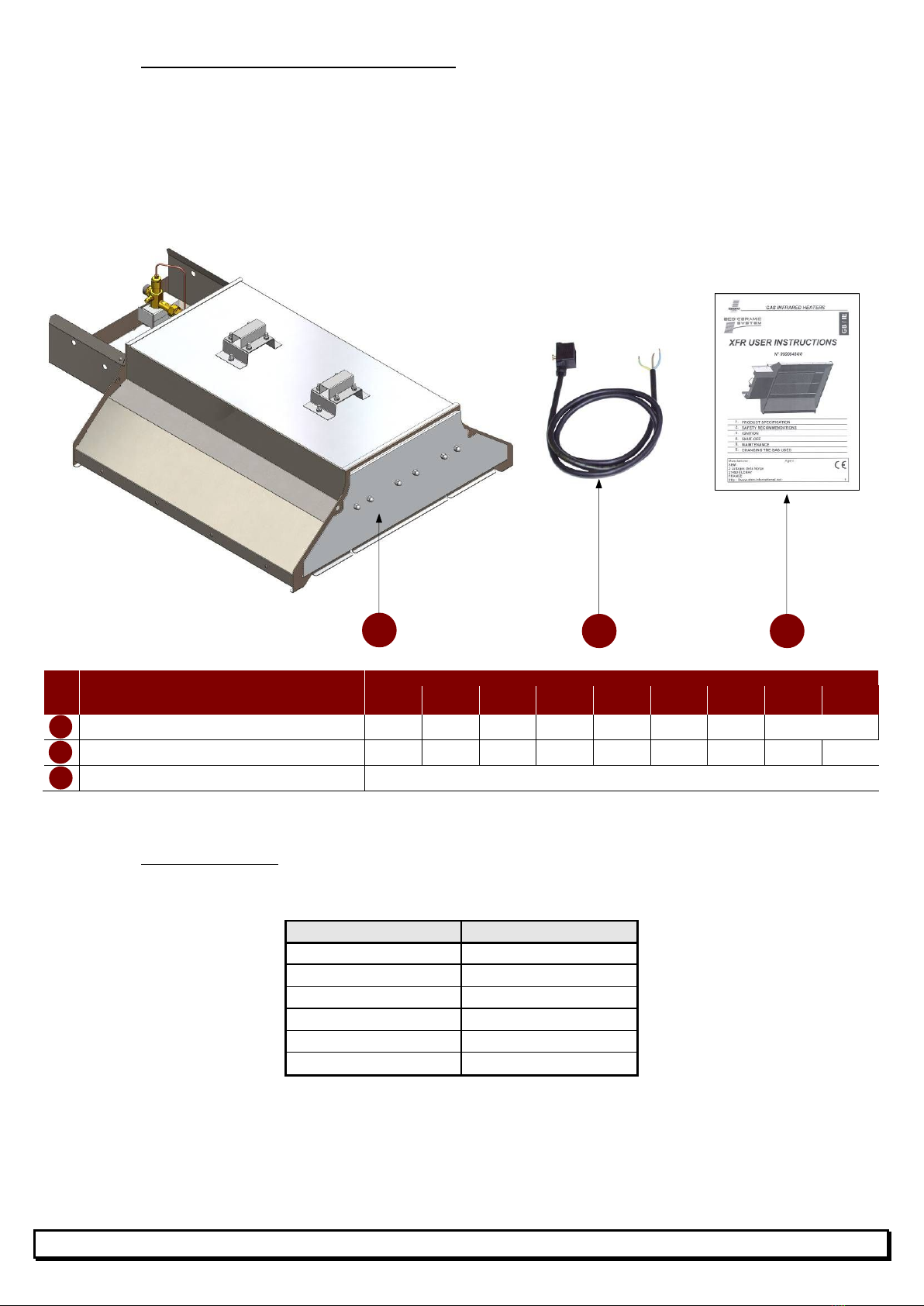

1.2 Technical specifications

GAS : G20 (Natural gas) - Category : I2H GB/IE

MODEL XFR 16 XFR 20 XFR 20-2

XFR 24 XFR 24-2

XFR 32 XFR 32-2

XFR 48-2

XFR 64-2

Certificat number 1312 CL 5522

Class NOx 4

Weight (kg) 14.60 14.60 15.20 16.10 16.70 19.50 20.10 see page 10

Nominal heat input :

Net calorific value ΣQn (Hi) (kW)

Gross calorific value ΣQn (Hs) (kW)

5.80

6.44

6.65

7.38

6.65

7.38

8.00

8.88

8.00

8.88

10.30

11.44

10.30

11.44

2x 8.00

2x 8.88

2x 10.30

2x 11.44

GAS

Nominale inlet pressure p (mbar) 20

Injection pressure pi (mbar) 16 14 14 15 15 16 16 15 16

Volumetric flow rate (m

/h) 0.620 0.703 0.703 0.846 0.846 1.090 1.090 2x 0.846

2x 1.090

Orifice (injector) (1/100 mm) 1x179 2x152 2x152 2x171 2x171 2x179 2x179 4x171 4x179

Primary orifice (restrictor) (1/100 mm) 1x278 1x260 2x194 1x321 2x212 1x401 2x278 2x321 2x401

Gas input connection Fitting G1/2" cylindrical (ISO 228-1)

ELECTRICITY

Power supply 230V (+10% -15%) – 50Hz Neutral mandatory

Consumption (VA) 28 28 2x 28 28 2x 28 28 2x 28 2x 28 2x 28

Individual fast acting fuse 5x20 (RP3 – RP32) 0.25A 0.25A 2x 0.25A

0.25A 2x 0.25A

0.25A 2x 0.25A

2x 0.25A

Ignition cycle length 45 seconds maxi

VENTILATION

Combustion air (m

/h) 6.01 6.82 6.82 8.20 8.20 10.57 10.57 2x 8.20

2x 10.57

Required air change (m

/h) 58.0 66.5 66.5 80.0 80.0 130.0 103.0 2x 80.0

2x 103.0

GAS : G31 (Propane) - Category : I3P GB/IE

MODEL XFR 16 XFR 20 XFR 20-2

XFR 24

XFR 24-2

XFR 32 XFR 32-2

XFR 48-2

XFR 64-2

Certificat number 1312 CL 5522

Class NOx 4

Weight (kg) 14.60 14.60 15.20 16.10 16.70 19.50 20.10 see page 10

Nominal heat input :

Net calorific value ΣQn (Hi) (kW)

Gross calorific value ΣQn (Hs) (kW)

5.47

5.95

6.65

7.23

6.65

7.23

8.00

8.70

8.00

8.70

10.30

11.20

10.30

11.20

2x 8.00

2x 8.70

2x 10.30

2x 11.20

GAS

Nominale inlet pressure p (mbar) 37

Injection pressure pi (mbar) 34 28 30 32 32 32 34 32 32

Mass flow rate (kg/h) 0.429 0.543 0.543 0.654 0.654 0.841 0.841 2x 0.654

2x 0.841

Orifice (injector) (1/100 mm) 1x119 2x99 2x99 2x106 2x106 2x119 2x119 4x106 4x119

Primary orifice (restrictor) (1/100 mm) 1x225 1x174 2x134 1x251 2x172 1x275 2x225 2x251 2x275

Gas input connection Fitting G1/2" cylindrical (ISO 228-1)

ELECTRICITY

Power supply 230V (+10% -15%) – 50Hz Neutral mandatory

Consumption (VA) 28 28 2x 28 28 2x 28 28 2x 28 2x 28 2x 28

Individual fast acting fuse 5x20 (RP3 – RP32) 0.25A 0.25A 2x 0.25

0.25A 2x 0.25

0.25A 2x 0.25

2x 0.25

2x 0.25

Ignition cycle length 45 seconds maxi

VENTILATION

Combustion air (m

/h) 5.09 6.44 6.44 7.76 7.76 9.98 9.98 2x 7.76

2x 9.98

Required air change (m

/h) 54.7 66.5 66.5 80.0 80.0 103.0 103.0 2x 80.0

2x 103.0

Hight radiant factor, up to 0.85 (EN 419-2)