COMPACT 75

COMPACT 75 Operator’s manual for drilling machine

4. GENERAL SAFETY ADVICE

COMPACT 75 drilling machine must not be used when:

1. The operator has not read the Operator’s Manual.

2. The work to be done is not in agreement with the recommendations in this Manual.

3. Drilling machine is not complete or has been repaired with non-original parts.

4. Power supply parameters do not confirm to those stated on the motor’s plate.

5. Machine’s operator has not checked condition of the drilling machine, condition of power

cable, control panel or cutter.

6. Power supply socket is not equipped with a protection circuit.

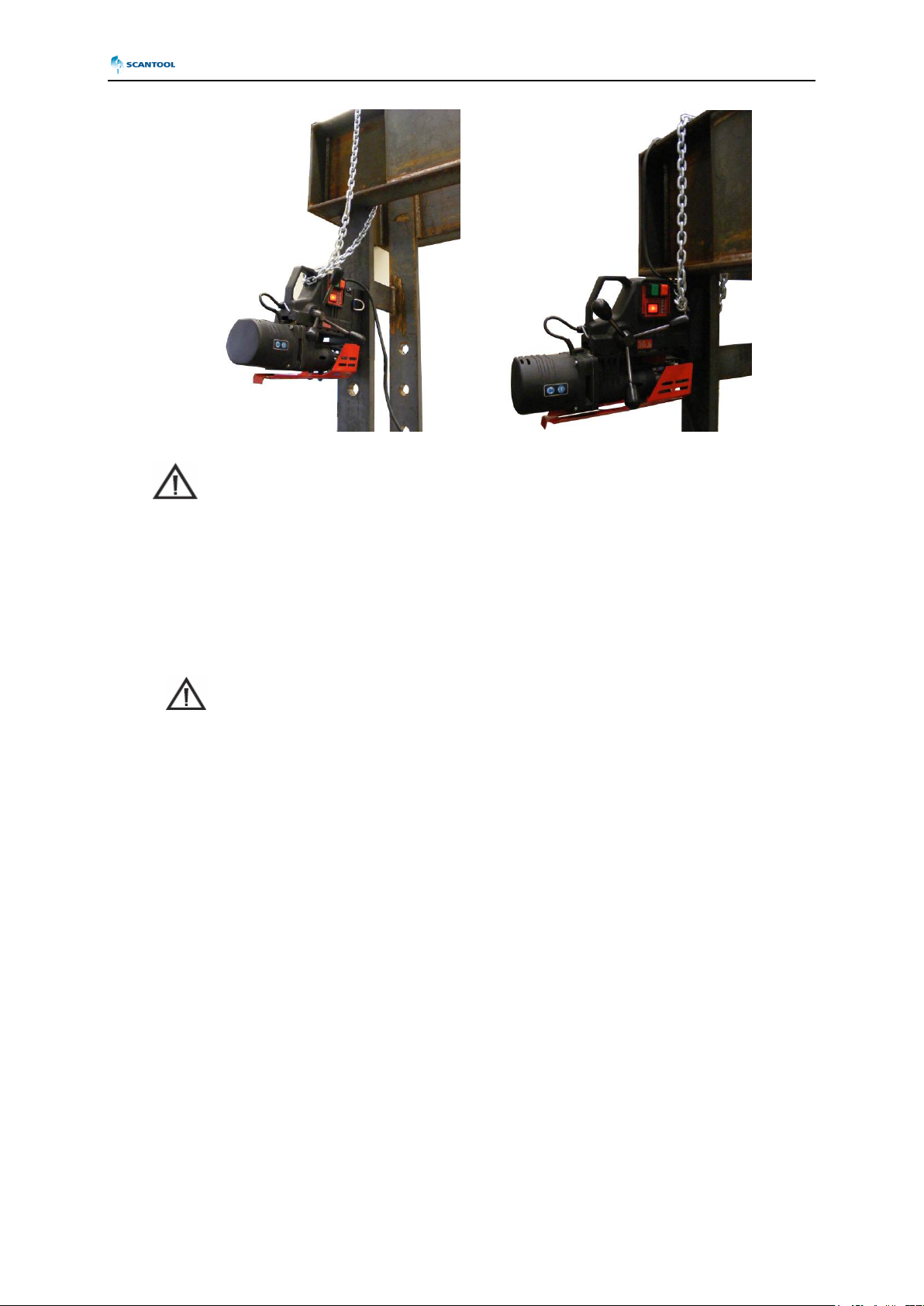

7. Machine is not secured with safety chain as a protection from falling down especially when

used at heights or in vertical or upside-down positions.

8. Bystanders are present in the immediate vicinity of machine.

Warning!

Read and save all instruction for future reference!

Important rules of safe use drilling machine on

electromagnetic base

1. Before attempting to work with the machine check the condition of electrical installation

including power cord and plug.

2. The drilling machine should be connected to an installation equipped with protection circuit

(grounding) and protected with a 16 A fuse for 220 V and 32 A fuse for 120 V. When used on

building sites, it must be supplied through a separation transformer made in the

second class of protection

3. Machine can be used outdoors, but is not weatherproof. Do not expose to rain, snow or frost.

4. Machine should not be used on: rusty surfaces, steel plates with thick covered with paint,

uneven surfaces, next to a welding machine.

5. In all cases always use a safety chain/strap (see Drawing No 1). The safety chain must not be

loose! To avoid this situation the safety chain should be wrapped around the element it is

hooked to.