Schaeff Echo 3000 User manual

Battery Rollers ..................................................1.1

Battery Gates ...................................................1.1

Overhead Guard

Removal .................................................1.1

Replacement ..............................................1.1

Rear Post

Removal .................................................1.2

Replacement ..............................................1.2

Front Cover

Removal .................................................1.2

Replacement ..............................................1.2

Top Cover

Removal .................................................1.2

Replacement ..............................................1.2

Control Cover

Removal .................................................1.3

Replacement ..............................................1.3

Operator Compartment Pads

Removal .................................................1.3

Replacement ..............................................1.3

Floor Mat / Brake Pedal Pad

Removal .................................................1.3

Replacement ..............................................1.4

High Back Pad

Removal .................................................1.4

Replacement ..............................................1.4

Decals ..........................................................1.4

ElectricCounterbalance High Output Frame

04/05/00 1.i

TABLE OF CONTENTS

Battery Rollers

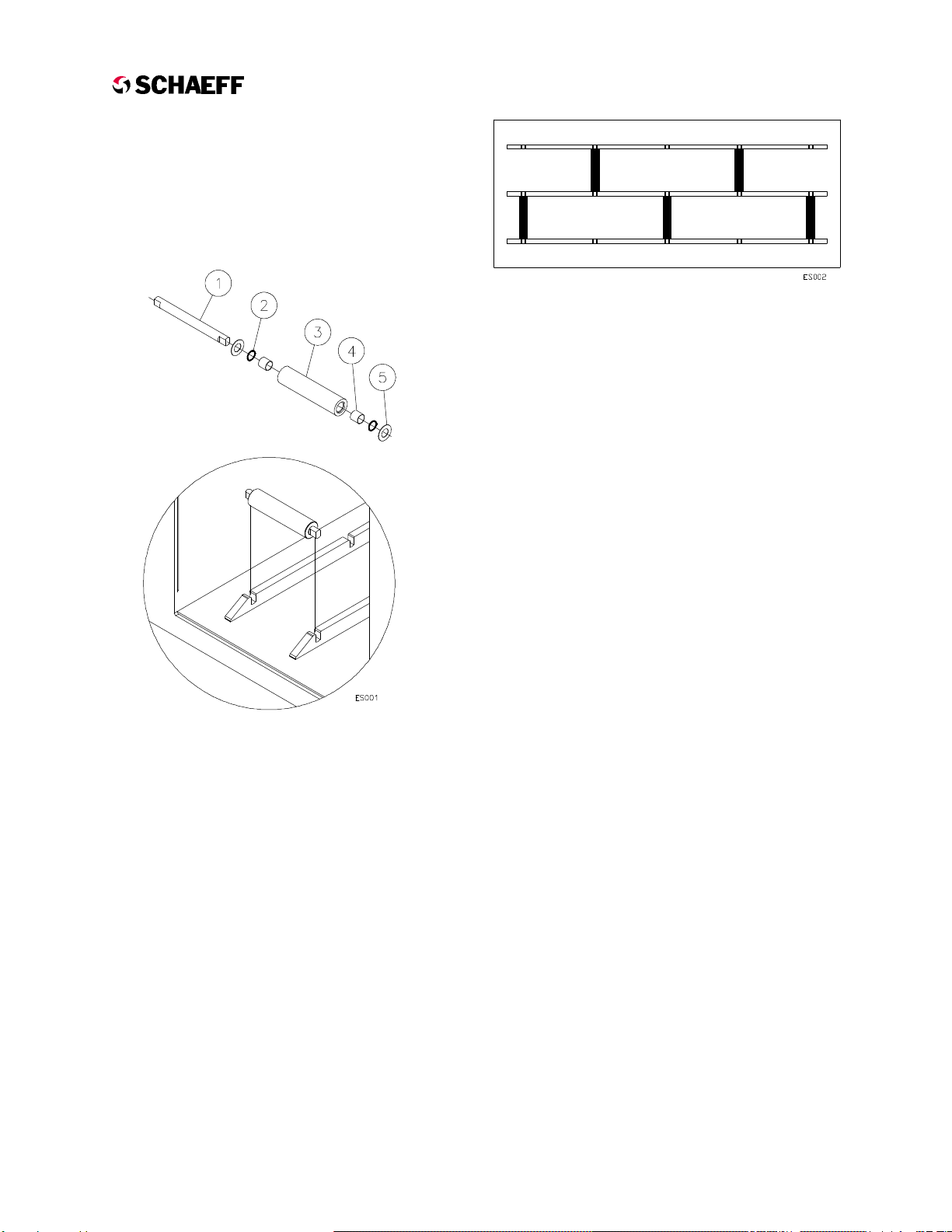

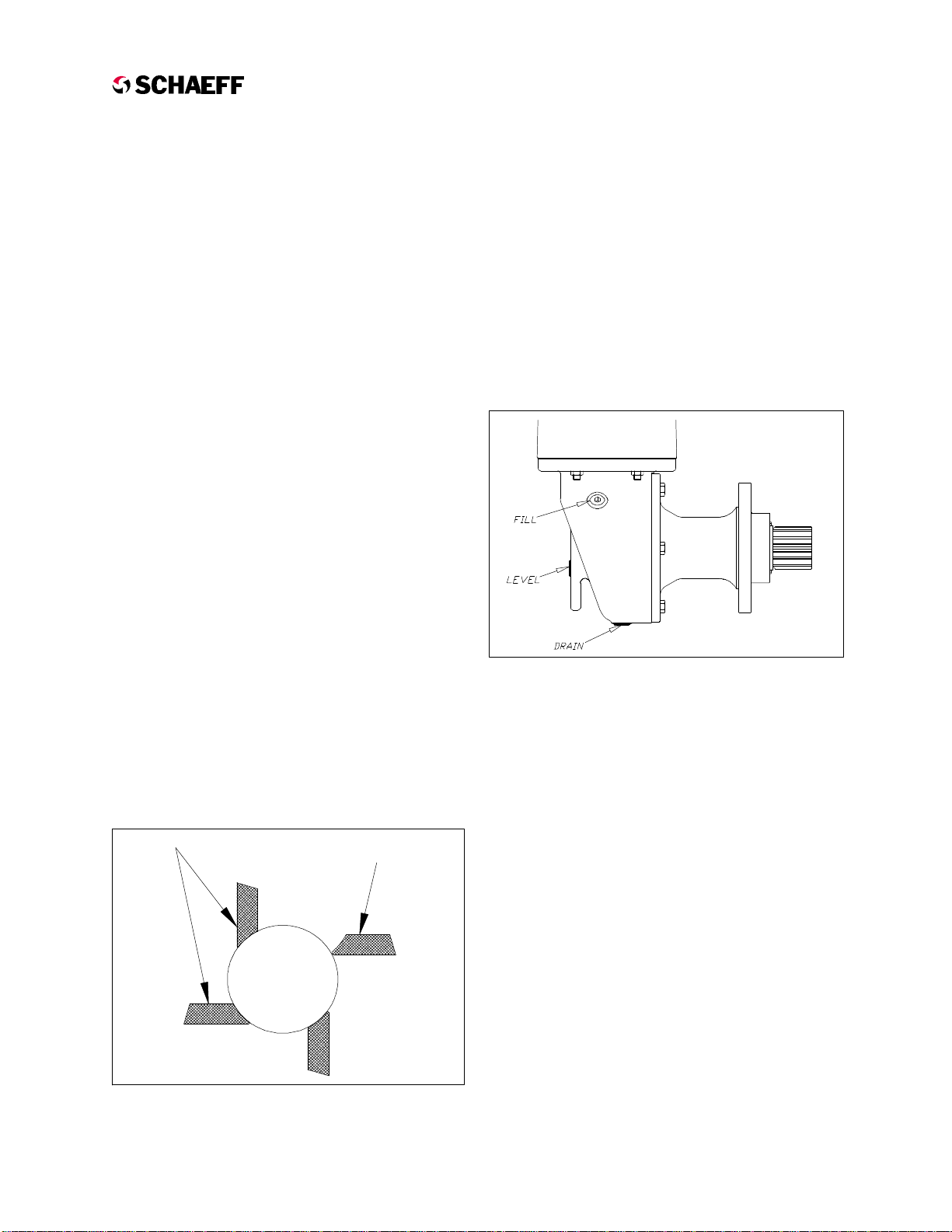

There are five battery rollers in the battery

compartment. They can be removed and

disassembled for cleaning or repair as shown in

Figure 1.1.

The battery rollers must be installed in the

compartment in the pattern shown in Figure 1.2.

Battery Gates

1.To remove a battery gate, slide the gate up so

that the rear tab lines up with the cutout in the

frame. Rotate the rear of the gate away from

the frame, and remove the gate.

2.To install a battery gate, insert the front tab of

the gate into the slot in the frame. Line up the

rear tab of the gate with the cutout in the

frame. Rotate the gate into the cutout and

slide the gate all the way down.

WARNING

Do not operate the truck with a battery gate

removed - the battery could slide out of the

compartment and could cause damage and/or

personal injury.

NOTE

The battery must not be able to slide more

than 1/2” in any horizontal direction. If

necessary, install spacers between the battery

and the frame to achieve this specification.

Overhead Guard

NOTE

Any modifications to the overhead guard must

be approved by the manufacturer.

Removal

1.Disconnect the battery and discharge the

capacitors. Remove the front cover and top

cover. Disconnect any accessory wiring on

the overhead guard (such as work lights or

flashing lights).

2.Attach a lifting device to the overhead guard

and take up any slack.

3.Remove the overhead guard mounting screws

from the front crossbar and rear post.

4.Use the lifting device to raise the overhead

guard off the truck. Do not allow the posts to

swing and damage any components of the

truck.

Replacement

1.Use a lifting device to position the overhead

guard directly over the truck.

2.Do not let the overhead guard legs swing and

damage components of the truck. Slowly

lower the overhead guard so that the

ElectricCounterbalance High Output Frame

REV W1 11/02/99 1.1

FIGURE 1.2 - Placement of Battery Rollers

1 Shaft

2 O-Ring

3 Roller

4 Bushing

5 Flat Washer

FIGURE 1.1 - Disassembly of Battery Rollers

mounting holes in the overhead guard line up

with the mounting holes in the frame. Install

the mounting screws and torque to 120ft.-lbs.

Install the rear post mounting screw and

torque to 120 ft-lbs.

3.Reconnect any accessory wiring. Install the

top cover and front cover.

REAR POST

Removal

1.Disconnect the battery and discharge the

capacitors. Remove the top cover.

Disconnect any accessory wiring through the

rear post (such as flashing light).

2.Attach a lifting device to the rear post and

take up any slack.

3.Remove the mounting screws from the lower

end of the rear post.

4.Remove the mounting screw at the top of the

rear post. Lower the post out of the overhead

guard, the nraise it out of the truck. Do not

allow the post to swing and damage

components in the truck.

Replacement

1.Use a lifting device to position the post in the

truck. Install, but do not tighten the mounting

screw at the top of the post.

2.Install the mounting screws at the bottom of

the rear post. Torque to 120 lb-ft. Torque the

upper screw to 120 lb-ft.

3.Connect any accessory wiring. Install the top

cover and connect the battery.

FRONT COVER

Removal

1.Tilt the mast to the full forward position.

2.Disconnect the battery and discharge the

capacitors.

3.The front cover is held by a spring clip that

engages the overhead guard crossbar. Pull

the front cover forward, away from the front of

the truck.

4.Once the top of the cover is released, lift

upward on the cover and remove from the

truck.

Replacement

1.Place the lower edge of the front cover into

the support channels.

2.Gently press the upper portion of the front

cover into place until the latch clicks into

position.

3.Connect the battery.

TOP COVER

Removal

NOTE

The top cover is held in place with 7frame

mounted spring-type retaining clips. This

cover does not require any tools to remove.

Care must be used when removing this cover

to avoid possible breakage.

1.Disconnect the battery and discharge the

capacitors.

2.Starting at the corner where the top cover

meets the control cover in the operator

compartment, gently pull up until the first

spring clips release the top cover.

3.As each spring clip on the left side releases

the top cover, move the handhold as close as

possible to the next spring clip. Gently pull up

until the cover is released from all of the

spring clips on the left side.

4.To release the right side of the cover, move

the battery disconnect forward, grasp the rear

edge of the opening, and gently pull upward.

5.Once the top cover is released from the spring

clips, lift the rear edge of the cover up until it

is clear of the rear leg of the overhead guard.

Move the entire cover toward the rear of the

truck until the top cover is free from the front

clip and the overhead guard.

6.Remove the cover from the truck.

Replacement

1.Tilt the top cover so that the front edge of the

cover is lower than the rear edge and slide

into place on the truck.

ElectricCounterbalance High Output Frame

REV W1 11/02/99 1.2

2.Align the cutouts on the front edge of the top

cover with the front posts of the overhead

guard. Move the front edge of the top cover

into place. Lower the rear of the top cover

into place.

3.Align the cut-outs in the lip of the cover with

the spring clips on the truck frame.

4.Press downward at each spring clip until the

cover is secured.

5.Connect the battery.

CONTROL COVER

Removal

1.Disconnect the battery and discharge the

capacitors.

2.Remove the top cover (refer to TOP COVER

Removal procedure in this section).

3.Remove the steering tiller.

4.Remove the seven screws securing the

control cover.

5.Lift the control cover over the control handle

and remove it from the truck.

Replacement

1.Place the control cover into position over the

control handle and start the seven screws - do

not tighten.

2.Install the steering tiller.

3.Position the cover so there is no contact with

the control handle boot or steer tiller, then

tighten the seven screws.

4.Replace the top cover (refer to TOP COVER

Replacement procedure in this section).

5.Connect the battery.

OPERATOR COMPARTMENT PADS

Removal

NOTE

The pads in the operator compartment are

secured in place with dual-lock fasteners.

When removing the pads, use care to avoid

detaching the fastener from either the pad or

the frame of the truck. If the fastener does

come loose, clean the area with isopropyl

alcohol and reattach it with cyanoacrylate

adhesive (“super glue”).

1.Remove the top cover.

2.Grasp the outside edge of the pad and

carefully separate the pad from the mating

portion of the fastener attached to the frame

of the truck.

3.Rotate the pad outward until the remainder of

the fasteners release.

4.Remove the pad.

Replacement

NOTE

Refer to PADS AND PLASTIC in the FRAME

section of the PARTS Manual for location of

operator compartment pads.

1.Align the pad so the halves of the fasteners

meet.

2.Firmly press the pad into place.

3.Gently pull on the outside edges of the pad to

verify the attachment.

4.Install the top cover.

FLOOR MAT /BRAKE PEDAL PAD

NOTE

The floor mat in the operator compartment is

not glued down. However, normal servicing of

the truck does not require the removal of the

floor mat.

Removal

NOTE

The brake pedal pad is secured in place with

general purpose RTV silicone adhesive. The

brake pedal pad will be damaged when

removed. It is recommended that a

replacement pad be available prior to removal

of the old pad.

1.Using an appropriate scraper, pry up the

outside edge of the pad.

2.Carefully peel the pad away from the brake

pedal.

ElectricCounterbalance High Output Frame

REV W1 11/02/99 1.3

3.Scrape the pedal surface to remove as much

of the old pad material as possible.

4.Clean any remaining residue from the pedal

with an appropriate solvent.

Replacement

1.On a properly prepared surface, apply a thin

film of adhesive to the brake pedal. (Follow

the manufacturer's instructions on the label of

the adhesive.)

2.Align the brake pedal pad with the brake

pedal.

3.Firmly press the pad into position.

4.Allow the adhesive to cure per the

manufacturer's recommendations.

HIGH BACK PAD

Removal

1.Remove the top cover (refer to TOP COVER

Removal procedure in this section).

2.Remove the two cap screws and brackets on

the bottom of the pad.

3.Lift the pad off the upper bracket and remove

it from the truck.

Replacement

1.Hook the top of the pad over the bracket at

the top of the frame.

2.Align the brackets with the lower brackets on

the truck frame and install flat washers, lock

washers and cap screws through each bracket

into the pad. Tighten the cap screws.

3.Install the top cover.

DECALS

Make sure all safety decals are in place and

readable. Replace worn or missing decals. Refer

to the PARTS Manual for decal location drawings.

ElectricCounterbalance High Output Frame

REV W1 11/02/99 1.4

Drive Train

Description.................................................2.1

Drive Unit

Removal...................................................2.2

Replacement................................................2.2

Drive Motor

Brush Replacement..........................................2.3

Gearbox

Oil Change.................................................2.3

Drive Wheel Assembly

Removal...................................................2.4

Replacement................................................2.5

Changing Drive Tires..............................................2.5

V-Ring Seal.......................................................2.5

Drive Wheel Spindle

Removal...................................................2.6

Replacement................................................2.6

Drive Unit Rebuild - Disassembly...................................2.7

Drive Unit Rebuild - Assembly

Pinion Gear to Motor Endbell Assembly ........................2.7

Gear Housing to Motor Assembly..............................2.8

Carrier to Gear Housing Assembly.............................2.9

Carrier Rebuild

Carrier Disassembly........................................2.11

Carrier Assembly...........................................2.11

ElectricCounterbalance High Output Drive

04/05/00 2.i

TABLE OF CONTENTS

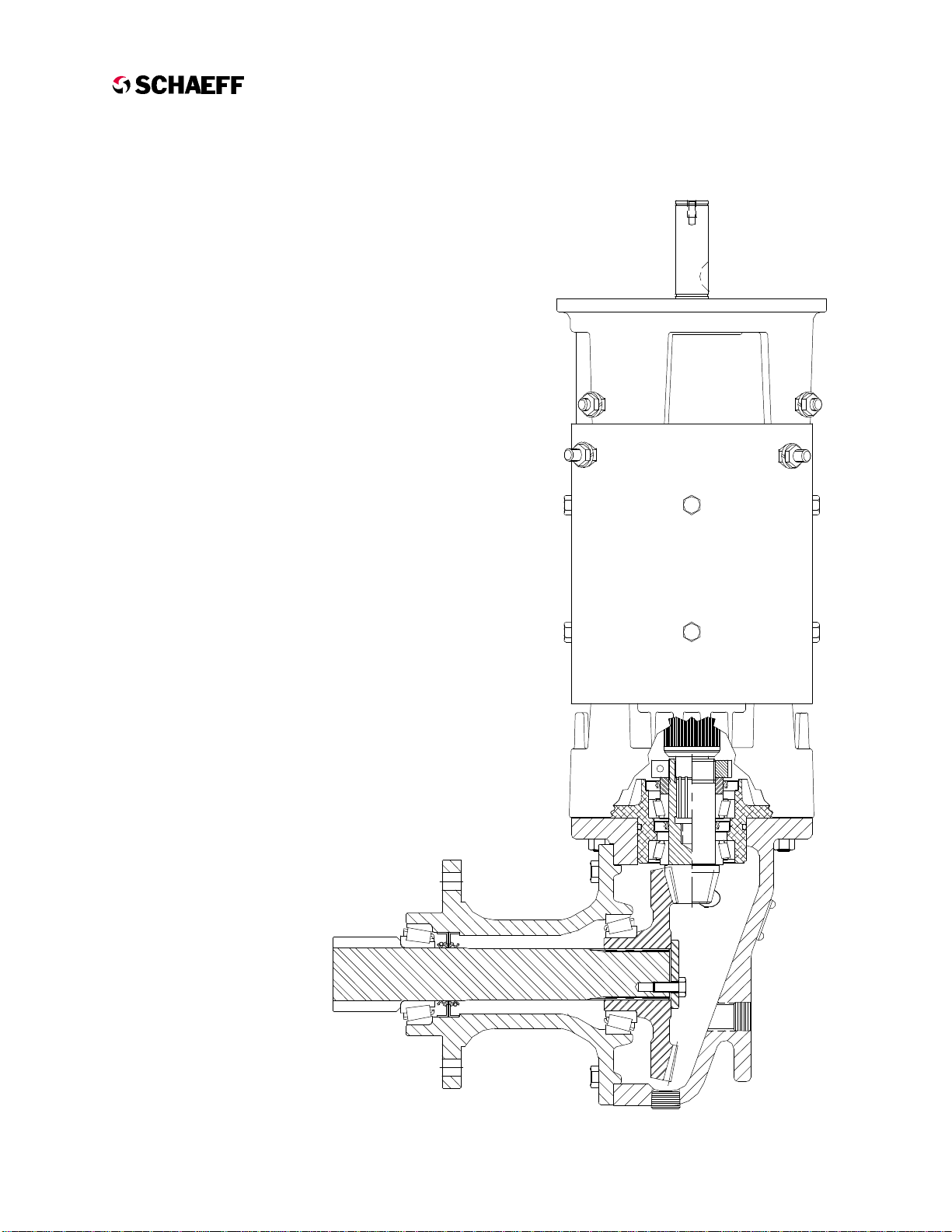

Drive Train Description

This lift truck is equipped with dual independent

drive trains. Each drive train consists of a drive

unit (drive motor and gearbox), and a drive wheel.

Traction drive is transmitted from the drive motor

to the gearbox through a pinion gear driven by the

motor armature shaft. From the gearbox, the

traction drive is transmitted to the drive wheel by

a pinion gear on the output end of the gearbox

which meshes with a ring gear mounted on the

inside of the drive wheel. The drive wheel rotates

on a spindle on the frame of the truck.

Each drive train is independently controlled by its

own traction amplifier. This allows the truck to

monitor and control the power output from each of

the drive units, improving the maneuverability of

the truck in tight areas. During turns, the inside

drive motor decreases speed to improve the

turning radius. In addition, each drive motor is

equipped with a disc-type brake to ensure positive

emergency stopping. Normal slowing or

deceleration is accomplished through "plugging"

of the motors.

NOTE

Specialized tools, fixtures, and training are

required to service any part of the drive unit

assembly.

ElectricCounterbalance High Output Drive

12/20/99 2.1

FIGURE 2.1 - DRIVE UNIT

Drive Unit

Removal

1.Disconnect the battery and discharge the

capacitors.

2.Remove the mast and front cover (refer to

Mast Removal procedure in the ELEVATING

section).

3.Put the truck on blocks or stands so the drive

wheels are completely off the ground.

4.Disconnect the power cables from the motor,

noting their location for correct replacement.

5.Remove the screws securing the drive unit to

the frame.

6.Tilt the drive unit forward so the motor is

vertical.

7.Remove the disc brake unit from the motor

(refer to Brake Removal in the BRAKES

section).

8.Remove the drive unit:

CAUTION

Ensure the lifting device has adequate

capacity to handle the weight of the drive unit

(approximately 140 lbs).

a)Attach a lifting device to the drive unit

for support and remove the slack.

b)Move the drive unit toward the center

of the truck, being careful not to

damage the hydraulic connection

block in the center of the frame.

c)Rotate the drive unit to clear the

pinion gear from the frame of the

truck. Use caution when rotating the

drive unit to prevent the pinion gear

from striking the frame of the truck.

d)Remove the drive unit from the truck.

9.Place the drive unit on a clean, secure work

surface.

Replacement

1.Install the drive unit into the truck:

CAUTION

Ensure the lifting device has adequate

capacity to handle the weight of the drive unit

(approximately 140 lbs).

a)Lubricate the drive pinion and outer

bearing (use a needle nose grease

gun to grease the outer bearing).

b)Connect a lifting device to the drive

unit.

c)Lift the drive unit into position in front

of the truck.

d)Carefully rotate the gearbox so the

pinion gear enters the opening in the

frame.

e)Rotate the drive wheel to engage the

pinion with the ring gear and slide the

gearbox pilot into the opening until the

flange is against the frame.

2.Install the disc brake unit (refer to Brake

Replacement).

NOTE

The drive unit is mounted to the frame with

four screws. Three screws are 1-1/2" long and

one is 1-1/4" long. The 1-1/4" screw goes in

the lower front hole (refer to DRIVE TRAIN in

the PARTS manual for an illustration).

3.Tilt the drive unit back to line up the mounting

holes. Install the four mounting screws and

torque to 80 lb-ft.

4.Connect the power cables to the correct

terminals on the motor. Plug in the brake unit.

5.Ensure the gearbox is filled with the proper

lubricant (refer to GEARBOX OIL CHANGE

procedure in this section).

6.Before lowering the truck off the blocks or

stands, connect the battery and test the drive

unit in Diagnostic Output Test 17 or 18 to

confirm proper operation.

7.Install the mast (refer to Mast Replacement

procedure in the ELEVATING section).

8.Install the front cover.

ElectricCounterbalance High Output Drive

12/20/99 2.2

Drive Motor

NOTE

Specialized tools, fixtures, and training are

required to service the drive motor. Refer to

DRIVE UNIT REBUILD in this section.

Brush Replacement

NOTE

wwReplace all the brushes in one motor as a

set.

wwUnits with brush wear indicators will have

one brush with an indicator wire. Note the

position of this brush for reassembly.

1.Tilt the mast to the full forward position.

2.Disconnect the battery and discharge the

capacitors. Remove the top cover and front

cover.

3.Remove the brake unit from one motor (refer

to the BRAKES Section).

4.Remove the armature cables from the motor,

noting their location for correct replacement.

5.Disconnect and remove the cooling fan from

the motor.

6.Remove the four 1/4” screws holding the

upper endbell to the drive motor.

7.Replace one brush and spring at a time.

Insert the new brush into the brush holder in

the correct orientation (see Fig. 2.2). Install

the brush spring, insuring it is in the proper

position. Tighten the brush lead screw to 15

-18 in.-lbs.

NOTE

If the unit has brush wear indicators, be sure

to install the new brush with the indicator wire

in the same brush holder and route the

indicator wire clear of the rotating armature.

8.Rotate the top endbellhousing to gain access

to the remaining brushes. When all eight

brushes and springs have been replaced,

return the endbell to its original position

(armature studs forward).

9.Reverse Steps 3 through 6 for reassembly.

10.Install the top cover and front cover. Connect

the battery and test the truck for proper

operation.

Gearbox NOTE

Specialized tools, fixtures, and training are

required to service any part of the gearbox.

Refer to DRIVE UNIT REBUILD in this section.

Oil Change

1.Disconnect the battery, discharge the

capacitors, and block the wheels of the truck

to prevent movement.

2.Place a clean drain pan under the appropriate

drive unit.

3.Remove the fill plug from the front of the

gearbox.

4.Remove the magnetic drain plug from the

bottom of the gearbox and allow the oil to

drain completely. Inspect the magnetic plug

and the used oil for excessive metal shavings.

ElectricCounterbalance High Output Drive

12/20/99 2.3

FIGURE 2.2 - BRUSH ORIENTATION

CORRECT INCORRECT

COMMUTATOR

FIGURE 2.3 - GEARBOX

5.Clean the threads of the drain plug, apply pipe

thread sealant to the plug and reinstall the

magnetic drain plug.

6.Remove the fluid level plug from the side of

the gearbox.

7.Fill the gearbox through the fill plug hole, with

Mobil SHC 50 Synthetic Gear Lubricant or

equivalent (SAE 80/90 Gear Oil may be

substituted if the truck is not used in Freezer

applications) until fluid level is even with the

bottom of the fluid level plug hole

(approximately 20 oz. for each gearbox).

8.Clean the old sealant from the threads of the

fluid level plug, apply new pipe thread sealant

to the plug and install the plug.

9.Clean the threads of the fill plug, apply pipe

thread sealant, and install the fill plug.

10.Remove the blocks from the wheels and

connect the battery. Test drive the truck and

inspect for leaks.

Drive Wheel Assembly

Removal

Special Tools: Drive Wheel Lock nut Tool, P/N

9650007

1.Disconnect the battery and discharge the

capacitors.

WARNING

Park the truck on a level surface. Block the

rear wheel to prevent the truck from rolling.

2.Lift the front of the truck and place it on

blocks.

3.Remove the drive wheel cover.

4.Bend the tabs of the lock washer out of the

slots in the spindle lock nut.

5.Use the lock nut tool to remove the lock nut

from the spindle. Remove the lock washer

with the lock nut.

CAUTION

The drive wheel assembly weighs 85 pounds

or more.

6.Remove the drive wheel assembly from the

spindle. The outer bearing will come off with

the wheel.

7.With the drive wheel off, the v-ringseal can

be inspected or replaced. Remove the v-ring,

ElectricCounterbalance High Output Drive

12/20/99 2.4

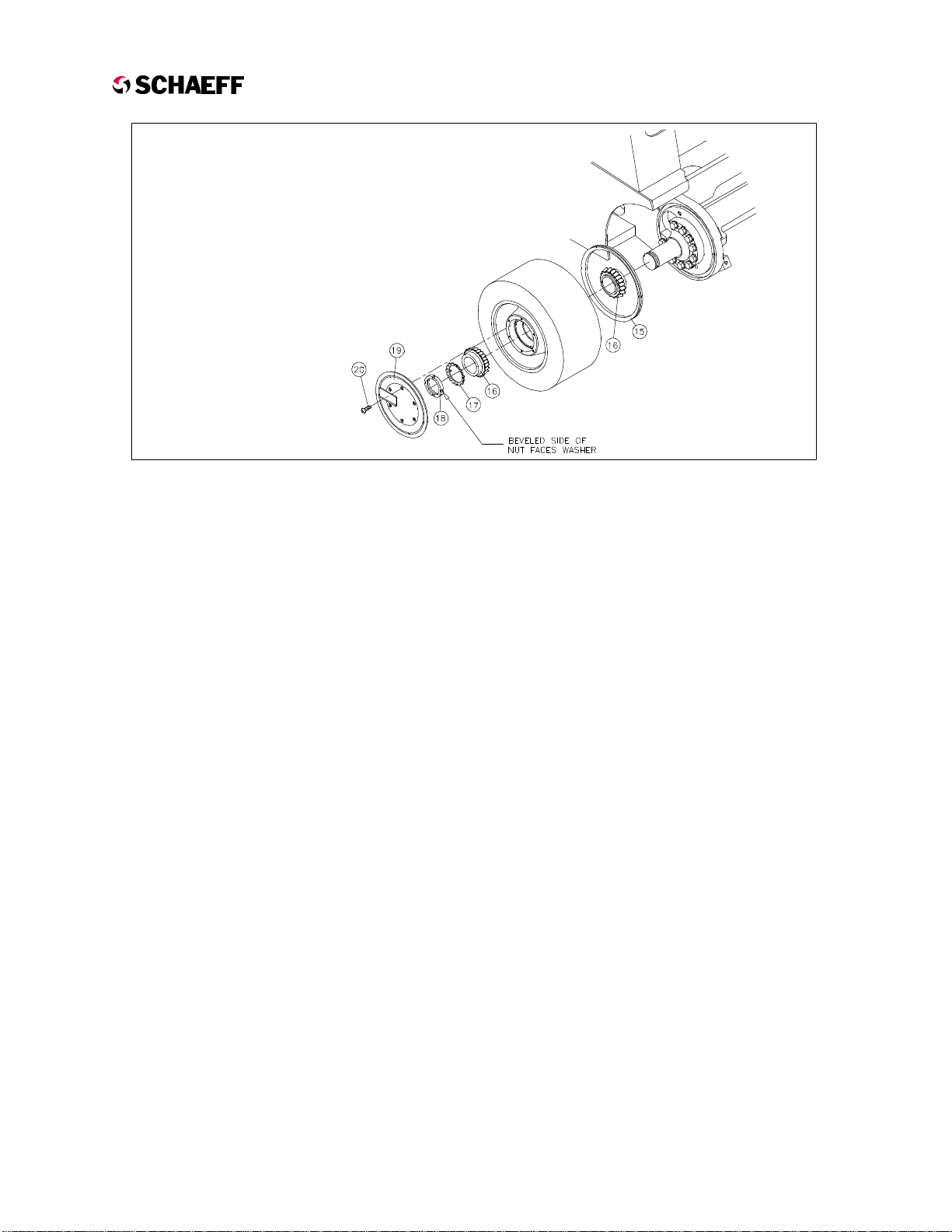

15 V-Ring Seal

16 Bearing

17 Tab Lock Washer

18 Lock Nut

19 Wheel Cover

20 Screw

FIGURE 2.4 - DRIVE WHEEL INSTALLATION

clean the groove, then apply a thin film of the

same lubricant used for the final drive gears

(Mobilith SHC 007 Synthetic Grease NLGI 00

or equivalent) to the v-ring seal.

Replacement

NOTE

Before installing the drive wheel assembly on

the truck, the outer drive pinion bearing, and

wheel bearings must be lubricated with

Mobilith SHC220 Synthetic Grease NLGI 2 or

equivalent. Use a needle tipped grease gun to

lube the outer drive pinion bearing with this

same grease. Lubricate the final drive gears

with Mobilith SHC 007 Synthetic Grease NLGI

00 or equivalent.

NOTE

DO NOT remove the ring gear from the inside

of the drive wheel. The ring gear is not

available as a separate part. If the ring gear is

damaged, replace the drive wheel assembly.

1.Pack both wheel bearings and place the inner

bearing on the spindle. Set the drive wheel

onto the spindle. Rotate the drive wheel so

the ring gear teeth mesh with the pinion gear

teeth, then push the drive wheel completely

onto the spindle.

2.Install the outer bearing. Line up the inner tab

of a new lock washer with the slot in the

spindle and install.

3.Carefully thread the lock nut onto the spindle

(beveled side toward the wheel). Seat the

bearings by tightening the nut to 60 lb-ft.

4.Back the lock nut off until a tab of the lock

washer can be bent into the lock nut.

5.Fasten the wheel cover onto the drive wheel.

6.Lower the truck off the blocks or stands and

remove the rear wheel blocks. Connect the

battery and test drive the truck for proper

operation.

NOTE

If the wheel bearings are not properly

adjusted, the drive wheel may lock up in one

direction.

Changing Drive Tires

Special Tools: Tire Changing Fixture (P/N

9650008), Tire Press (40 ton)

NOTE

There is a flange at the back of the drive wheel

that can be broken if the wheel is improperly

pressed.

1.Remove the drive wheel assembly (refer to

procedure in this section).

2.Place the larger ring of the tire changing

fixture on the press table. Place the wheel

and tire, ring gear down, on top of the ring,

making sure the ring does not touch the

wheel. Center the smaller ring on top of the

wheel. Press the wheel out of the tire.

NOTE

When replacing the drive tire, make sure the

composition and size are such that

maneuverability and capacity are maintained.

3.Place the new tire on the press table. Align

the wheel on top of the tire with the ring gear

up. Press the wheel into the tire.

4.Install the drive wheel assembly.

V-Ring Seal

See Drive Wheel Removal.

ElectricCounterbalance High Output Drive

12/20/99 2.5

FIGURE 2.5 - CHANGING DRIVE TIRES

Drive Wheel Spindle

Removal

1.Remove the drive wheel (refer to the

procedure in this section).

2.Remove the screws attaching the spindle to

the frame. The spindle is very heavy. DO

NOT let the spindle drop and damage the

threads or the bearing surfaces.

Replacement

1.Clean old thread locking compound and oil

from the holes and bolts before reassembly.

2.Align the cutout in the spindle with the hole in

the frame. Insert two screws to keep the

spindle in place.

3.Install the remaining screws and lock washers

with a small amount of thread lock compound.

Tighten to 80 lb-ft.

4.Remove the first two screws, apply thread

lock compound, and reinstall with lock

washers. Tighten to 80 lb-ft.

5.Install the drive wheel.

6.Test drive the truck for proper operation.

ElectricCounterbalance High Output Drive

12/20/99 2.6

FIGURE 2.6 - DRIVE UNIT ASSEMBLY

Drive Unit Rebuild - Disassembly

1.Remove the drive unit from the truck.

CAUTION

DO NOT pry the sections apart - this may

damage the machined surfaces. If necessary,

use a rubber mallet to separate the sections.

2.Remove the four nylon lock nuts (Figure 2.6

Item 14) and separate the gearbox from the

motor. Note the thickness of the shim

package.

3.Remove the six screws (Figure 2.6 Item 26)

and separate the carrier from the housing.

Note the thickness of the old shim package,

then discard.

4.If necessary, remove the bottom endbell

(including the pinion gear) from the motor.

There may be shim material around the motor

shaft in the pinion gear.

5.Remove the O-ring (Figure 2.6 Item 12) and

discard.

6.To disassemble pinion:

a.Loosen the screw on the side of the clamp

nut (Figure 2.6 Item 2) and remove the

clamp nut using the pinion locknut wrench

(P/N 9660099) and 3/8” drive pinion

wrench (P/N 9660154-01).

b.The spacer (Fig. 2.6 Item 3) and bearings

(Fig. 2.6 Item 5) are pressed onto the

pinion gear. Carefully press the pinion

gear out of the endbell. Press the lower

bearing off the pinion gear. Remove the

upper seal to remove the upper bearing

from the endbell.

c.To replacethe lower seal, press both the

seal and the upper bearing cup out

together.

Drive Unit Rebuild - Assembly

Pinion Gear to Motor Endbell Assembly

NOTE

wwBefore assembling the drive unit, all

components and machined surfaces must

be thoroughly cleaned of any dirt, grime,

gasket compound, etc. Machined surfaces

must be cleaned only by using a soft cloth

and mild, non-abrasive cleaning solvent.

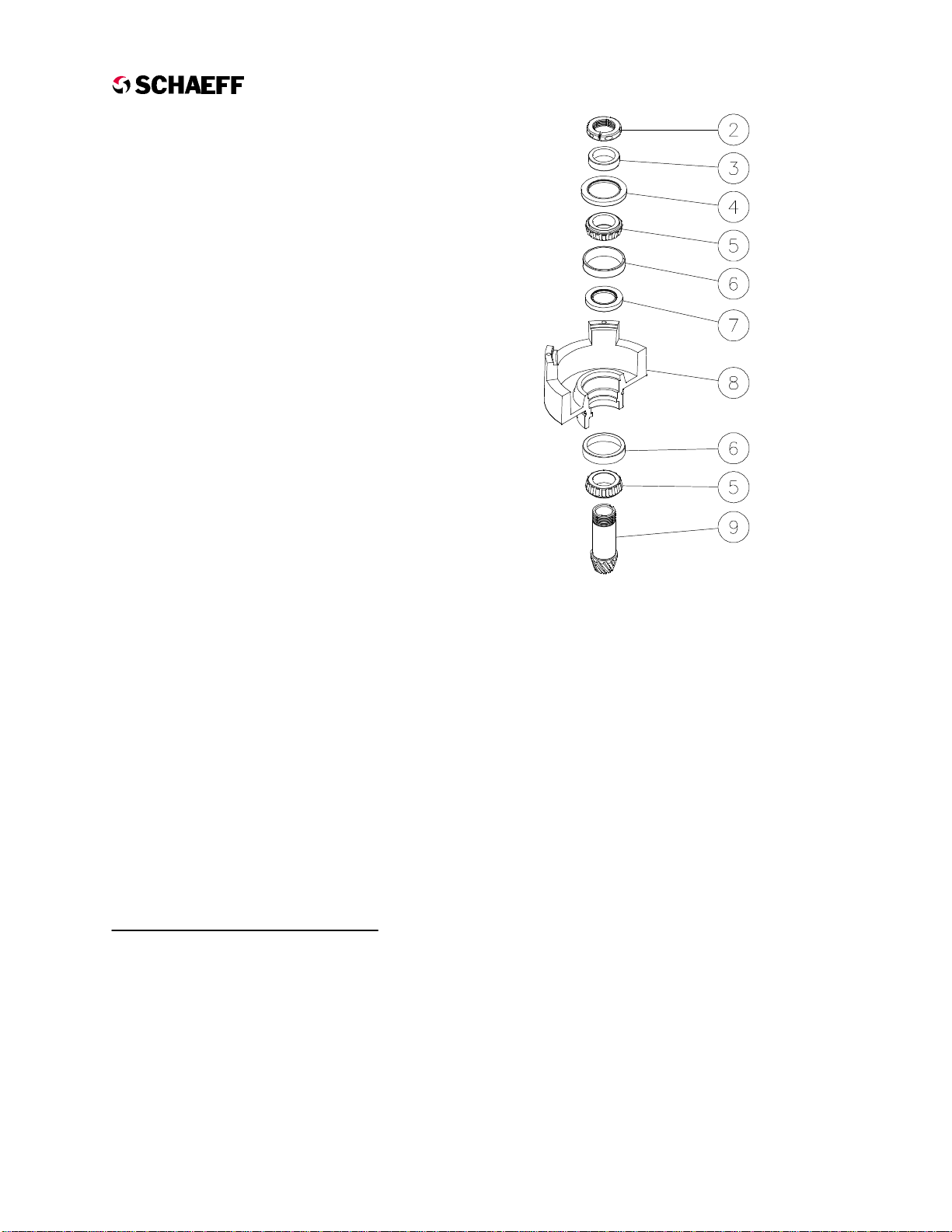

1.Refer to Figure 2.7 to assemble the pinion

gear to the motor endbell:

a.Install the lower seal (lip down) and the

lower bearing cup.

b.Pack the upper bearing with Mobilith SHC

220 synthetic grease (or equivalent)and

lubricate the lip of the lower seal. Press

the lower bearing all the way onto the

pinion using the pinion bearing press die

(P/N 9660100).

c.Cover the threads on the pinion to prevent

damaging the seal. Slide the pinion

through the endbell and remove the

thread covering.

d.Use a hand press and the pinion bearing

press die (P/N 9660100) to press the

upper bearing and spaceronto the pinion

shaft. Rotate the endbell housing while

pressing. Stop pressing when slight drag

can be felt.Fill the upper bearing cavity

with MobilithSHC 220 synthetic grease

(or equivalent), then install the upper seal.

ElectricCounterbalance High Output Drive

12/20/99 2.7

Figure 2.7- Pinion Gear to Endbell Assembly

Install the clamp nut (Fig. 2.7, Item 2) and

torque the screw in the side of the clamp

nut to 70 in-lb.

NOTE

Tightening the screw in the clamp nut will

increase the turning torque on the pinion.

Always measure the turning torque with the

clamp nut installed and the locking screw on

the side tightened.

e.Measure the turning torque on the pinion

using the 1/4” drive pinion wrench (P/N

9660154-00) and a torque wrench. The

turning torque should be 13-17 in.-lbs. If the

turning torque is greater, loosen the clamp nut

and make slight adjustments with a hand

press on the pinion. If the turning torque is

less, slight adjustment can be made by

tightening the clamp nut, or remove the clamp

nut and make slight adjustment with a hand

press on the spacer.

2.Apply anti-seize compound to the motor shaft

spline. Attach the endbell to the motor. If

shim stock was removed during during

disassembly, replace it only if using the same

motor.

3.Install a new O-ring (Fig 2.6, Item 12) on the

motor pilot flange.

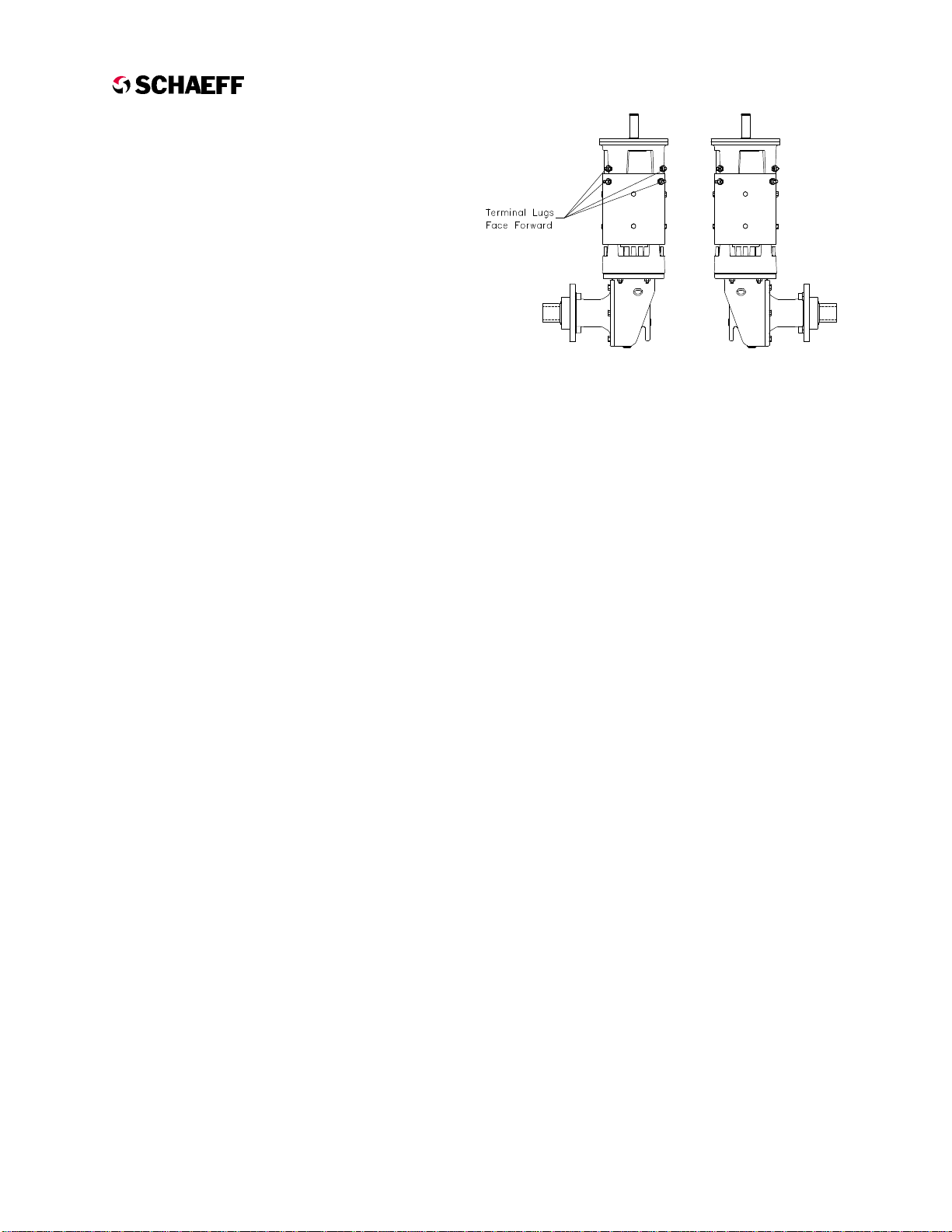

Gear Housing to Motor Assembly

NOTE

Before assembling the gear housing to the

motor, you must first determine whether you

are to build a left or a right drive unit. As an

assembler holds a drive unit with the brake

end of the motor up and the terminal lugs

pointing forward, a right drive unit would be

assembled with the gearbox pointing to the

right; a left drive unit would be assembled

with the gearbox pointing to the left (see Fig.

2.8).

1.Determine the thickness of the 4-hole shim

package required between the motor endbell

and gear housing. The thickness of the shim

package is determined by one of the

following formulas:

Use Procedure 1 when you have both the

number on the end of the pinion, and the

number on the gearbox housing.

A + B - C = Shim package

Refer to Fig. 2.9 Procedure 1

Use Procedure 2 when the number on the

end of the pinion is illegible or there is no

number.

D + 2.061 - C = Shim Package

Refer to Fig. 2.9 Procedure 2

Ais the distance from the back surface of the

pinion gear to the mounting face of the motor

Measure using the Pinion Height Dial Indicator

(P/N 9650004) zeroed at 1.000”. To get the

correct distance, measure to the top of the

bearing , not to the endbell casting surface.

The number should be around 1.40”

Bis the distance from the back face of the

pinion gear to the theoretical center of the

matching ring gear. This number is etched on

the end of the pinion gear. If this number is

not legible or there is no number, use

Procedure 2.

Cis the distance from the center of the

gearbox housing to the mounting face of the

motor mounting face. This number is

stamped on the back of the gear housing

casting. The stamped number may or may

not begin with a four. If the number reads

4.611, for example, record this number as

Distance C. If the number reads only .611, for

example, assume a four at the beginning.

Distance Cwould therefore be 4.611.

Dis the distance from the end of the pinion to

the mounting face of the motor. If the number

on the end of the pinion is not legible, then

measure D using the Pinion Height Dial

Indicator zeroed at 2.500” . The number

should be around 2.57”

ElectricCounterbalance High Output Drive

12/20/99 2.8

Figure 2.8 - Drive unit orientation.

RIGHT LEFT

Example for Procedure 1:

Measurement A= 1.394

Etched on Pinion B= 3.240

Stamped on Gearbox C= 4.611

1.394 + 3.240 - 4.611 = 0.023

4-Hole Shim Package = 0.023"

Example for Procedure 2:

Measurement D= 2.573

Add 2.061

Stamped on Gearbox C= 4.611

2.573 + 2.061 - 4.611 = 0.023

4-Hole Shim Package = 0.023

2.Assemble a 4-hole shim package as

determined in Step 1 (verify thickness with a

micrometer) and install on the motor mounting

face.

3.Remove the carrier assembly from the gear

housing. Apply a thin coat of grease to the

outer diameter of the motor pilot flange and

secure the gear housing to the motor using

four 3/8-16 nylon lock nuts (torqued to 30 lb-ft)

as either a left or right drive unit as required.

Carrier to Gear Housing Assembly

1.Place a 6-hole shim package (Fig. 2.6, Item

18) over mounting flange on gear housing.

Initially use 0.022” or the same thickness that

was removed during disassembly.

2.Coat an approximately 30oarea of the ring

gear with marking compound for checking the

tooth contact pattern.

ElectricCounterbalance High Output Drive

12/20/99 2.9

Figure 2.10 - Carrier to Housing Alignment

Procedure 2

Measure D if there

is no number on

the end of pinion.

Procedure 1

Measure A if there is

a number on the end

of pinion.

Figure 2.9 - CALCULATE 4-HOLE SHIM THICKNESS.

Correct

alignment

Incorrect

alignment

NOTE

When installing carrier to gear housing,

ensure alignment of flange mounting holes is

correct (see Fig. 2.10)

3.Place the carrier on the gear housing ensuring

gear teeth are meshed. Temporarily fasten by

tightening at least three of the six screws

supplied with the gearbox. Rotate the pinion

gear to make sure it turns freely.

4.Attach the drive unit backlash tool to the

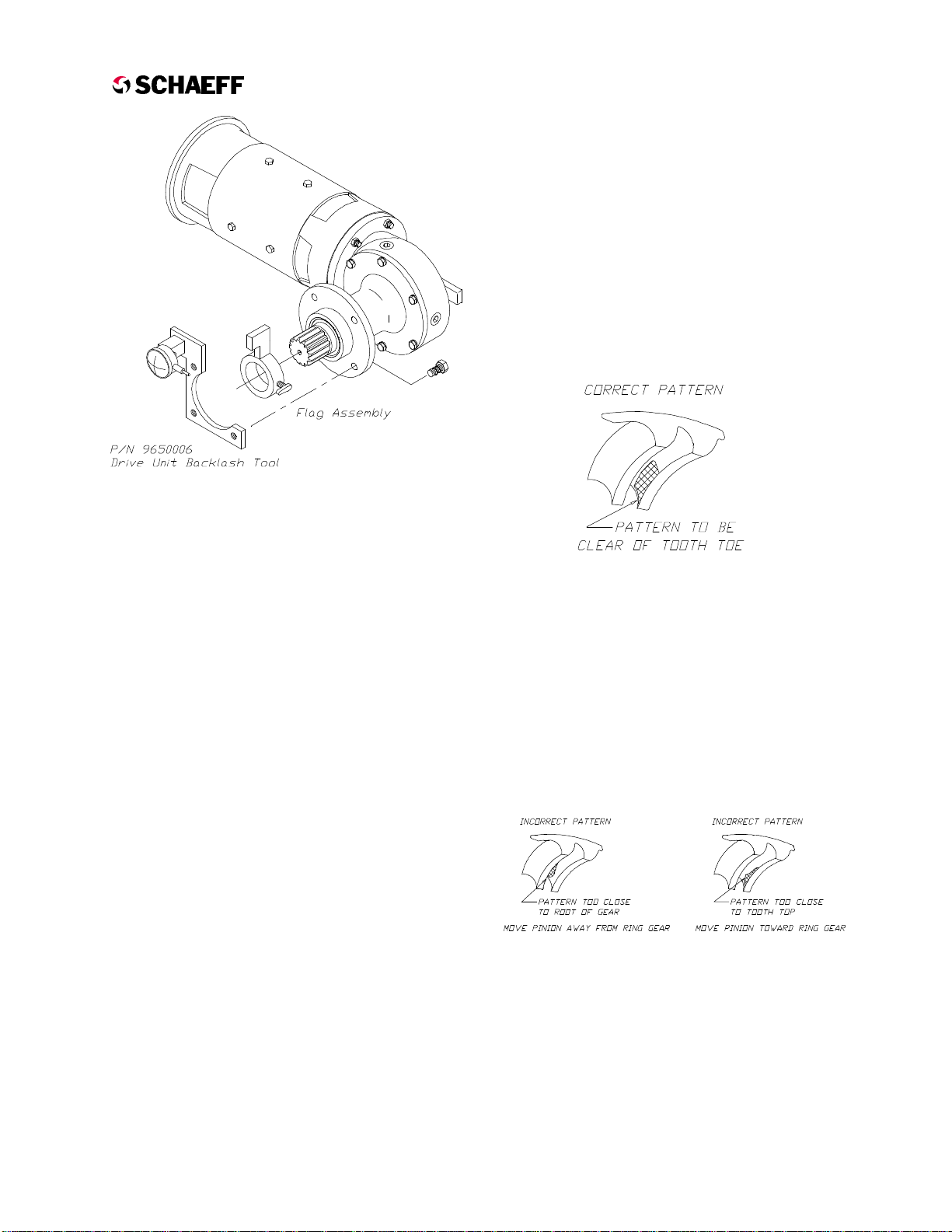

gearbox as shown in Fig. 2.11. Make sure the

dial indicator is aligned as shown.

5.Install the flag assembly on the spur gear with

the flag in the upright position.

6.Rotate the flag until it moves about halfway

into the dial indicator's range of motion.

Then, rock the flag back and forth (firmly, but

not hard enough to rotate the motor shaft) and

observe the dial indicator readings. The

difference between the highest and lowest

reading is the backlash. Backlash should be

greater than 0.003" but should not exceed

0.013". Check backlash at every other tooth

for a full revolution. If this condition is not

met, disassemble the carrier from the gear

housing and add or remove shims as required

(if backlash is too great, remove shims; if

backlash is too small, add shims). Repeat

these steps as necessary until backlash

conditions are met.

7.Once backlash conditions are met, remove

the flag assembly and backlash tool. Rotate

the motor shaft several revolutions both

forward and reverse. Remove the carrier

from the gear housing and observe the

contact pattern on the gear:

a. The correct pattern, as shown in

Example 1, is well centered on the bevel gear

tooth with lengthwise contact clear of the toe.

The length of the pattern in an unloaded

condition is approximately one-half to

two-thirds of the bevel gear tooth. The

backlash (6-hole) and motor to gear box

(4-hole) shims are correct.

b. Example 2 indicates an incorrect 4-hole

shimming package between the motor and the

gear housing. The contact pattern in the left

illustration indicates that the pattern is too

close to the root of the gear tooth or off the

tooth root. If this condition occurs, add some

4-hole shims between the motor and the

gearbox and test again. The illustration to the

right shows a pattern that is too close to the

tooth top land and off center. If this condition

exists, remove some 4-hole shims between

the motor and gearbox and test again.

c. Example 3 indicates a backlash error

caused by an incorrect 6-hole shim package

between the carrier and the gear housing. The

illustration to the left shows the pattern too far

off the tooth toe. As was noted in Example 1,

there should be an area between the contact

ElectricCounterbalance High Output Drive

12/20/99 2.10

Example 2

Example 1

Figure 2.11 - Backlash Tool

pattern and the tooth toe that is not in contact

with the gear set. To correct for this condition,

remove the carrier from the gear housing, add

additional shims, reassemble and test again.

The illustration to the right however shows the

pattern moving too far along the tooth toward

the tooth heel. To correct for this condition,

remove the carrier, remove some shims,

reassemble and test again.

8.Once gear teeth pattern conditions are met,

remove carrier from gear housing and set the

shim package aside. Apply a thin coat of

suitable gasket compound to mounting

surfaces of the carrier and housing then

replace shim package. Reattach carrier to

housing using the six bolts supplied with the

gearbox and a thread locking compound.

Torque to 40 lb-ft.

9.Using grease gun containing Mobilith SHC

220 grease, ensure the cone bearing on gear

shaft is greased.

10.Ensure motor terminal lugs are tight.

11.Reinstall drive unit into the truck.

Carrier Rebuild

Carrier Disassembly

NOTE

The bearings on the drive shaft are pressed on

with an interference fit. Disassembly is

recommended only when one of the carrier's

bearings or seals need to be replaced or the

carrier has excessive endplay (greater than

0.002"). Refer to DRIVE UNIT REBUILD -

DISASSEMBLY for disassembly of the drive

unit.

1.Place the carrier assembly with the spiral

bevel gear facing up.

2.Remove the three cap screws (Fig. 2.6, Item

19) securing the bevel gear to the pinion

shaft.

3.Remove the cap (Fig. 2.6, Item 20) and any

shims underneath.

4.Lift the spiral bevel gear off of the pinion

shaft.

5.Slide the pinion shaft out of the carrier

housing.

6.Remove bearings, bearing cups, and seals as

necessary, being careful not to damage gear

teeth or machined surfaces.

Carrier Assembly

1.Ensure castings and machined surfaces are

clean and free of foreign material. Clean only

with a rag and mild non-abrasive solvents.

2.Stand carrier housing on end with large

mounting flange down.

3.Lubricate the outside diameter of the seals

(Fig. 2.6, Item 27), and carefully press into the

housing individually. Ensure that the lip of the

first seal is downward . Ensure that the lip of

the second seal is pointing upward.

4.Lubricate outside diameter of the bearing cup

(Fig. 2.6, Item 28), and press evenly into the

carrier housing until properly seated against

the stop.

5.Turn the carrier housing over so that the large

flange is pointing up. Lubricate bearing cup

(Fig. 2.6, Item 24), and press evenly into the

carrier housing until properly seated against

the stop.

6.Pack the cone roller bearing (Fig. 2.6, Item

29) with MobilithSHC 220 grease, or

equivalent. Stand the pinion shaft on end with

the spur gear down. Lubricate the inside

diameter of the packed cone roller bearing

and press evenly onto pinion shaft as shown

until properly seated against the spur gear.

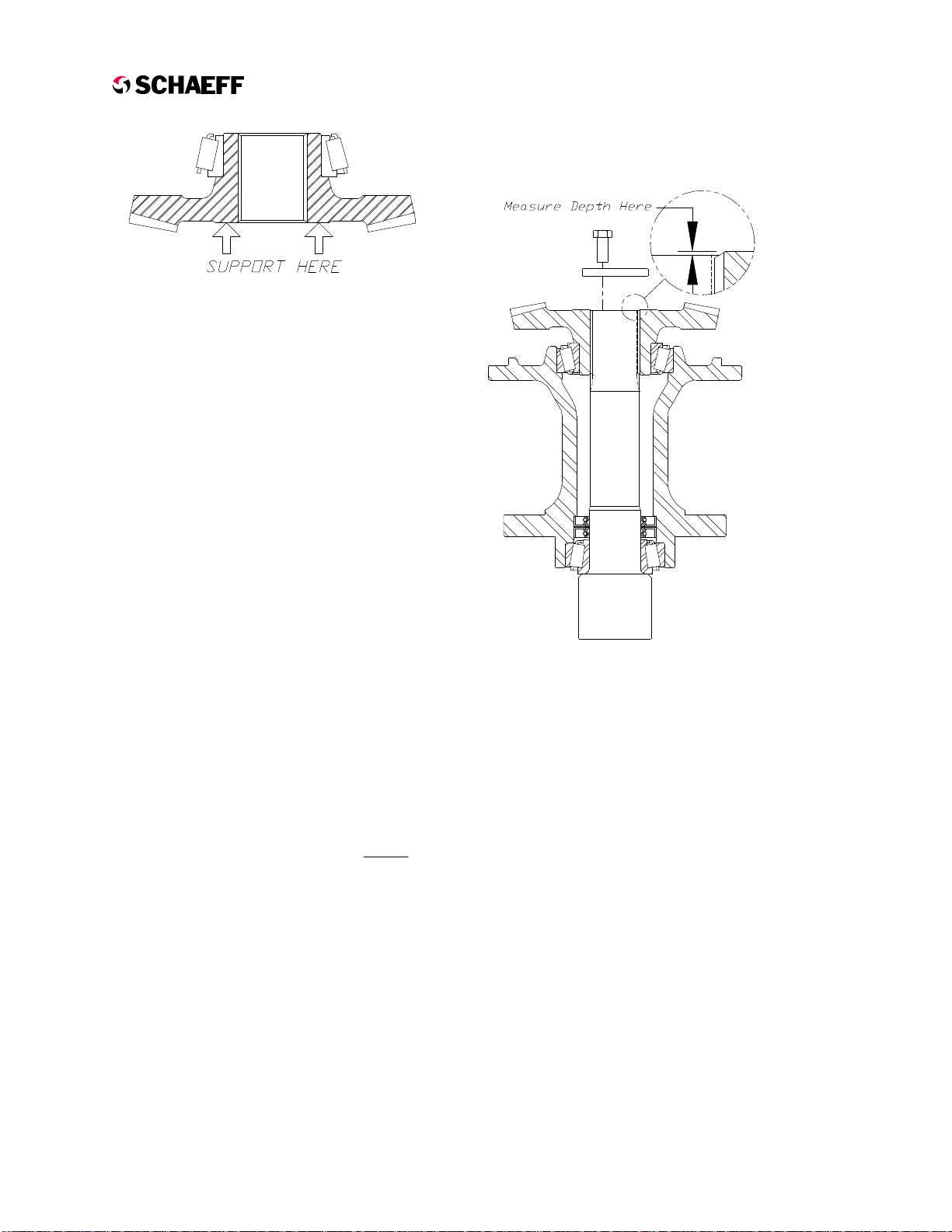

7.Place the bevel gear face down with support

under the center section opposite the bearing

seat preventing the gear teeth from being

damaged (see Fig. 2.12). Lubricate the inside

diameter of the cone roller bearing (Fig. 2.6,

Item 23) and press onto the bevel gear as

shown until properly seated against the stop.

This bearing should not be packed with heavy

grease. It will eventually be lubricated by

gearbox oil in the gear housing.

ElectricCounterbalance High Output Drive

12/20/99 2.11

Example 3

8.Lubricate the inner diameter of the seals

installed in Step 3 above. Using a twisting

motion, insert the pinion shaft through the

carrier housing.

9.With the spur gear end of the shaft in the

downward position on the table, install the

bevel gear over splined end of the shaft.

10.Apply light pressure to the bevel gear and

shaft. Spin the carrier housing several times

to seat the bearings.

11.Place the cap (Fig. 2.6, Item 20) over the

spiral bevel gear and secure using three

5/16-18 screws (Fig. 2.6, Item 19). Torque

bolts to 20 lb-ft to ensure bearings and

bearing cups are seated properly. Remove

the three bolts and the cap.

12.Using a depth micrometer, measure and

record the depth from the face of the bevel

gear to the end of the pinion shaft (see Fig.

2.13). A carrier shaft shim package (Fig. 2.6,

Item 21) should be assembled 0.003" greater

than the recorded bevel gear to pinion shaft

depth. Verify shim package thickness using a

micrometer; then place the package on pinion

shaft end.

Example: Measured Depth =0.010"

Add 0.003 =0.003" +

Total Shim Package =0.013"

13.Place the cap over the shim package and

secure using three 5/16-18 screws. Torque to

20 lb-ft.

14.Again, spin housing to seat bearings.

15.Invert the carrier with ring gear down and

place supporting blocks on the mounting

flange at the bolt circle diameter. This will

suspend the ring gear.

16.Place a magnetic base indicator on the small

flange end of the carrier with indicator probe

on end of spur gear.

17.Pry upward on the cap to observe the

endplay. Add or remove shims as necessary

until an endplay of 0.000" to 0.002" is

obtained.

NOTE

If there is no endplay, and the pinion shaft

cannot be turned freely by hand, the bearings

are too tight. Increase the shim thickness

under the cap.

18.Remove retaining bolts and reassemble using

a permanent thread locking compound with a

minimum temperature rating of at least 450o

F. If there are no wire tie holes in the bolts,

torque to 20 lb-ft.

19.Refer to DRIVE UNIT REBUILD - ASSEMBLY

to reassemble the drive unit.

ElectricCounterbalance High Output Drive

12/20/99 1.12

Figure 2.13 - Measure Shim Depth

Figure 2.12 - Support Spiral Bevel Gear

Brake System

Theory of Operation ........................................3.1

Disc Brake Unit

Description ...............................................3.2

Removal .................................................3.2

Disassembly ..............................................3.2

Assembly .................................................3.2

Replacement ..............................................3.3

Brake Pedal

Removal .................................................3.3

Replacement ..............................................3.4

Brake Adjustments

Brake Pedal Height ........................................3.4

Brake Switches ............................................3.4

Braking Force (Clamping Pressure) ...........................3.5

ElectricCounterbalance High Output Brakes

04/04/00 3.i

TABLE OF CONTENTS

Theory of Operation

The brake system of this lift truck is to be used as

a parking brake and for emergency stopping only.

Slowing or stopping the lift truck is normally done

through "plugging" of the traction motors.

Plugging is a method of slowing the rotation of the

drive wheels by changing the direction of current

flow through the traction motor. In an emergency,

the truck can be stopped by lifting the foot off of

the brake pedal.

The brake system is designed to mechanically

apply the brakes when the operator removes his

foot from the pedal. The brakes are electrically

released when the operator depresses the pedal.

The brake system consists of a brake pedal, an

electric brake relay, and two self-contained disc

brake units. The disc brake units are attached to

the commutator end of the drive motors to take

advantage of the increase in torque supplied by

the gearbox.

Internal coil springs in the disc brake units supply

the force which clamps the rotating friction plate.

An electric solenoid coil acts against these springs

to release the brakes. The friction plate floats on

the arbor so that equal pressure is applied to both

sides.

When the operator releases the brake pedal, two

micro-switches are actuated. One signals the

system controller to cut power to the traction

motors. The second signals the brake relay to cut

power to the disc brake units, thus applying the

brakes. The system controller does not monitor

the operation of the disc brake units or the relay.

NOTE

Many of the brake adjustments interact with

one another. When performing any

adjustments on the brake system, please

follow the order of the list below. When

servicing the brakes, check all of the

adjustments listed below (See Brake

Adjustments).

1.Brake Pedal Height

2.Brake Switch Adjustment

3.Disc Brake Air Gap

4.Braking Force (Clamping Pressure)

The brakes should stop a fully loaded truck on a

dry, level floor within 1.1 feet per MPH the truck is

traveling. For example a fully loaded truck

traveling 6 MPH should stop within about 6.6 feet.

The brakes should hold a fully loaded truck on a

10% grade.

ElectricCounterbalance High Output Brakes

REV W1 12/02/99 3.1

Table of contents