PALLET TRUCK ASSEMBLY

Note: Individual trucks are assembled and ready to use. Pallet trucks purchased in crate quantities (6 units to a crate) require some assembly.

Tools needed for assembly: hammer, flat screwdriver, 14mm wrench

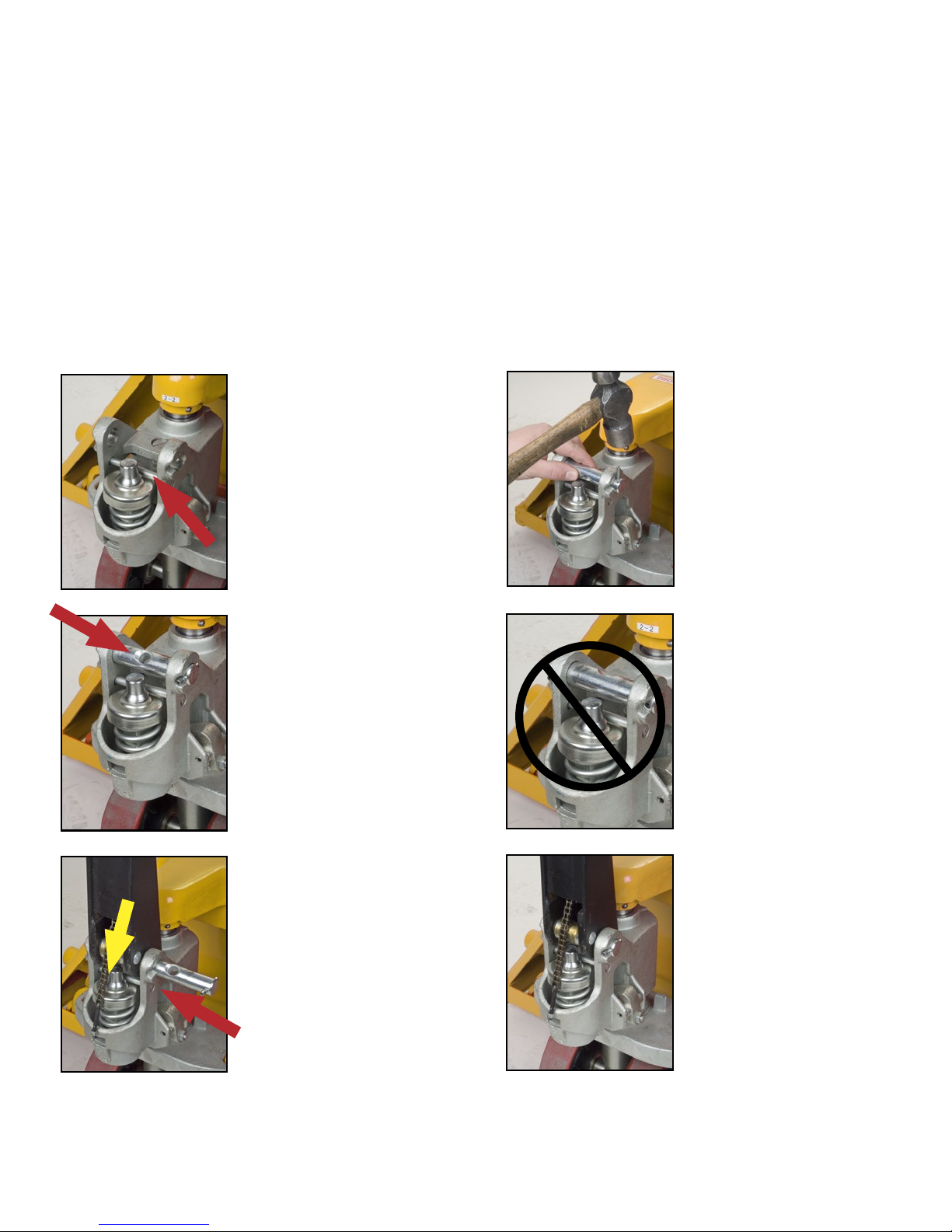

*** IMPORTANT - SAFETY ***

Verify that spring safety pin is in place. The pin

should be well rested in the holes situated on

each side of the pump housing. If the safety pin

is not rested properly in one of the holes, put

pressure on the spring using a “C" clamp push-

ing down on the pump stem. Once pressure is

relieved on the pin, reinsert properly and remove

clamp slowly,

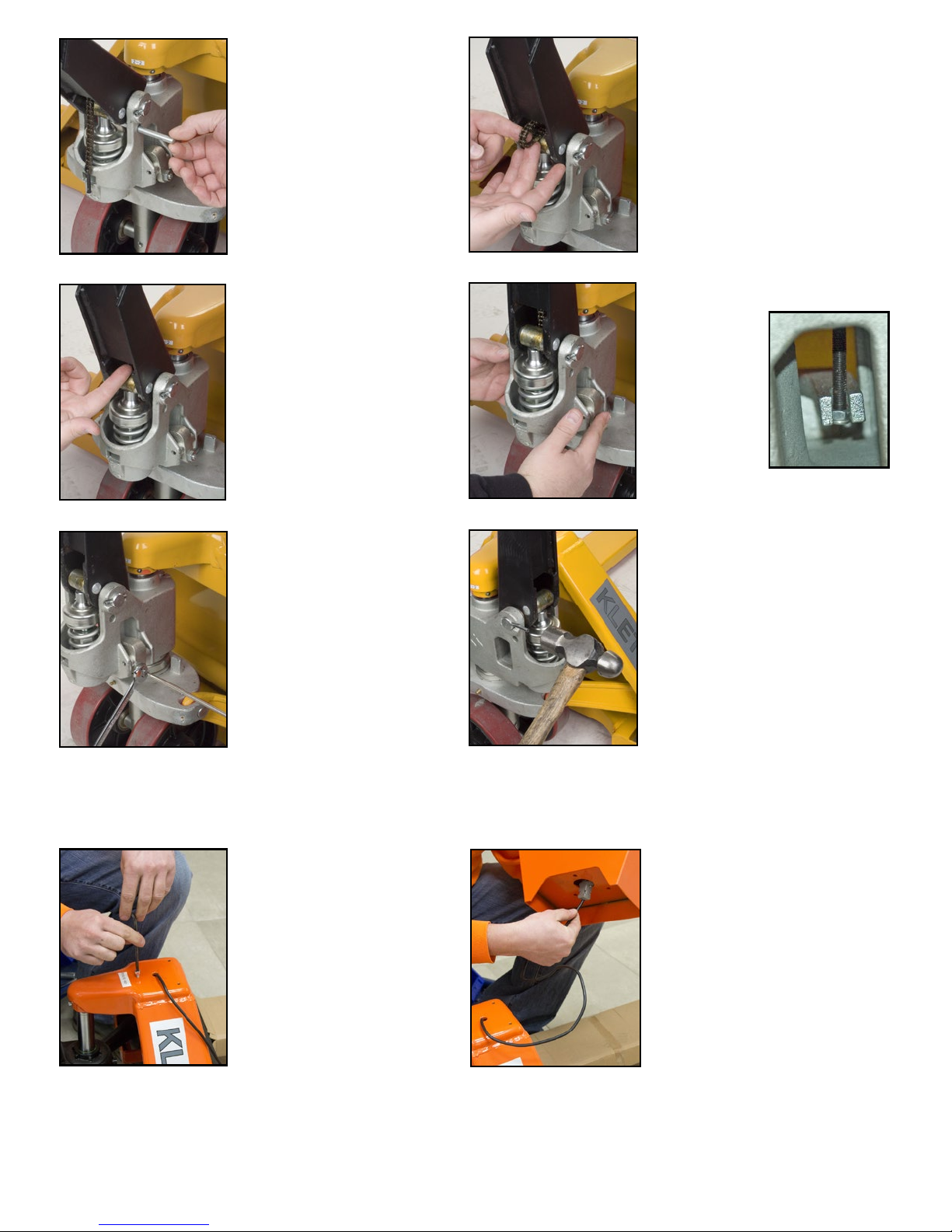

TO ATTACH HANDLE ASSEMBLY TO THE FRAME:

If handle pin’s center hole is

facing away from you, insert

pin from other side.

*** IMPORTANT - FACT ***

The up/down lever’s chain passes

through this center hole. If left this way,

the chain will have an “S" form and be

under too much tension, making the up/

down lever difficult to use accurately.

1.

Insert handle pin without the handle and

verify that the center hole is facing you.

3. 4.

Insert handle pin into corresponding

holes and using a hammer, drive in one

spring pin on one side only.

2.

WARNING!

• Read and understand the entire operator’s manual before using the pallet truck.

• Don’t load pallet truck beyond rated capacity of 4,400 lbs.

• Secure load before transporting.

• Keep the load centered on the pallet.

• Don’t operate loaded pallet truck on ramps or inclines.

• Always wear appropriate safety shoes.

• Never leave a loaded pallet truck unattended in the raised position;

always lower load to the floor.

*** IMPORTANT - CHAIN****

Before this step, make sure to feed the

chain on the outside of the piston stem

roller (see yellow arrow). If left in its

proper position, it will not be possible to

insert the handle pin and chain, break-

age may occur.

Align handle holes with pump housing

holes and push through handle pin (see

red arrow)

Make sure that handle pin is completely

through the handle and resting on the

other side.

5. 6.

2