Before Initial Operation

© BT Industries AB 180424-040

7

Before Initial Operation

•Please read this manual thoroughly. This will give you a

complete understanding of BT industrial vehicles and permit

you to operate them correctly and safely.

Proper handling of new vehicles promotes performance and

extends service life. Drive with special caution while becom-

ing familiar with a new vehicle.

In addition to the standard operating procedures, pay atten-

tion to the following safety items.

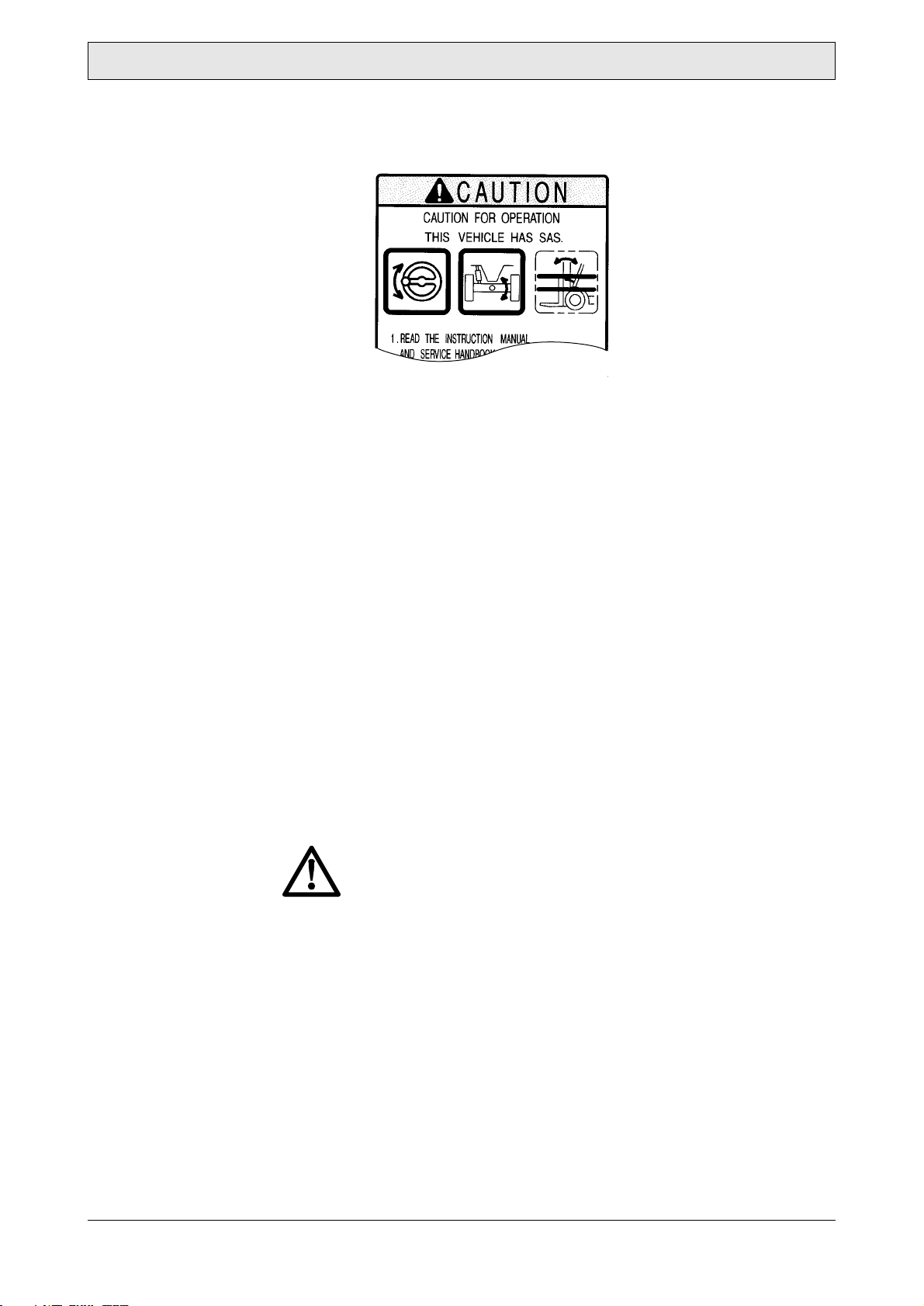

•Please acquire thorough knowledge on BT industrial

vehicle. Read the operator’s manual thoroughly prior to oper-

ating the vehicle. Get to know its operation and components.

Learn about the safety devices and accessory equipment and

their limits and precautions. Be sure to read the caution plate

attached to the vehicle.

•Please learn safe driving points and safety management.

Understand and maintain working area traffic rules. Ask the

work area supervisor about any special working precautions.

•Wear neat clothing for operation. Improper clothing for

vehicle operation may interfere smooth operation and cause

an unexpected accident. Always wear proper clothing for

easy operation.

•Please keep away from live electric power lines. Know the

locations of inside and outside power lines and maintain suffi-

cient distance.

•Be sure to perform pre-operation check and periodic

maintenance. This will prevent sudden malfunctions,

improve work efficiency, save money and insure safe working

conditions.

• Always warm up the engine before starting operation.

•Be sure to avoid forward tilt when the loaded fork is

raised. In the worst case, this will cause overturning due to

poor stability resulting from forward shifting of the center of

gravity.

•Never attempt traveling with a loaded on the lifted fork

beyond the specified height. Traveling with a load on the

fork lifted beyond the specified height may cause overturning

due to upward shifting of the center of gravity. Keep the fork

at 10-20cm (5.9-7.9in)above the ground when traveling.

•Please avoid overloading or uneven loading. Overloading

or uneven loading is dangerous. If the center of gravity is

nearer to the front side even though the load is below the

maximum, limit the loading weight according to the load table.

• If you hear and unusual noise or sense anything unusual,

inspect and repair immediately.