Document 57.0008.7200 - 05/2007

Page 1

Handler with telescopic boom

GTH-3512

■

I

NTRODUCTION

This handbook provides information for a safe and

proper operation and maintenance of the machine.

STRICTLY COMPLY WITH THE INSTRUCTIONS

GIVEN IN THIS HANDBOOK!

READ AND UNDERSTAND THIS HANDBOOK

BEFORE STARTING, USING AND CARRYING

OUT ANY OPERATION WITH AND ON THE

MACHINE.

The handbook is divided into seven sections:

Sect. A GENERAL INFORMATION

Sect. B SAFETY

Sect. C OPERATING INSTRUCTIONS

Sect. D MAINTENANCE

Sect. E TROUBLESHOOTING

Sect. F OPTIONAL ATTACHMENTS

Sect. G TABLES AND ENCLOSURES

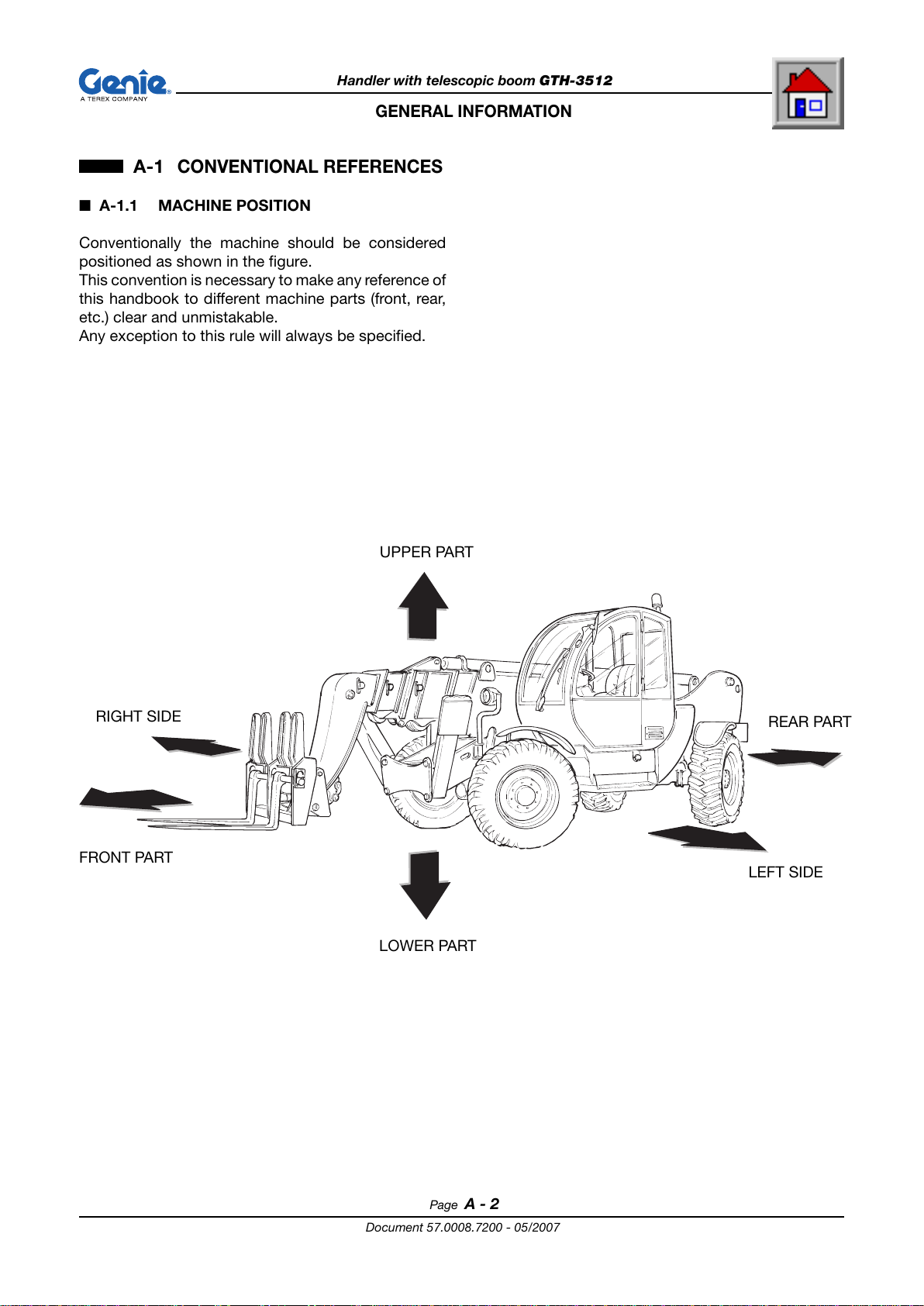

Section Acontains general concepts that are decisive

for the knowledge of the main parts of the machine.

It also contains all necessary data for a correct

identification of the machine, the technical features of

the machine, etc.

Section Bis especially addressed to the personnel,

who shall operate, repair and service the machine, and,

in case of companies with a wide fleet of machines, to

those responsible for safety.

It describes the essential compulsory qualities of the

personnel in charge and other important information

for the safety of persons and things.

Section Cis mainly addressed to the operators who

operate the machine. This section illustrates all control

devices.

Additionally, it contains the main use instructions -i.e.

engine starting, machine parking, machine storing.

Section Dis addressed to those responsible for

maintenance and the servicemen.

The section describes the maintenance schedule and

the relevant intervals.

Section E deals with the failure diagnostics.

Section Fmakes a list of the main interchangeable

attachments that can be coupled to the machine:

dimensions, weight, application field and limits of use.

Section Gcontains tables and various enclosed

documents like load charts, wiring diagrams, hydraulic

schemes, torque wrench setting table, etc.

Sections are subdivided into chapters and paragraphs

that are numbered progressively.

The quickest way to look for information is the reference

to the general index or the titles of the single chapters

and paragraphs that represent keys for an easy

consultation.

Take care of this handbook and keep it in an

accessible place within the machine, even

after its reading, so that it will always be

within reach if in doubt.

If you are unsure about anything, please address to

GENIE Assistance Service or to your agent/dealer:

addresses, phone and fax numbers are printed in

the cover and in the title-page of this manual.

IMPORTANT

Any difference between the contents of this manual

and the real functional character of the machine

can be attributed to either a machine manufactured

before the issue of this manual or to a manual going

to be updated after some changed effected on the

machine.

Always contact GENIE Assistance Service for any

updated version of this manual and any additional

information.

INTRODUCTION

Courtesy of Crane.Market