2019/10/07 Operating manual/BEAROMOS 2020/Version 1.0

Page 3 of 26

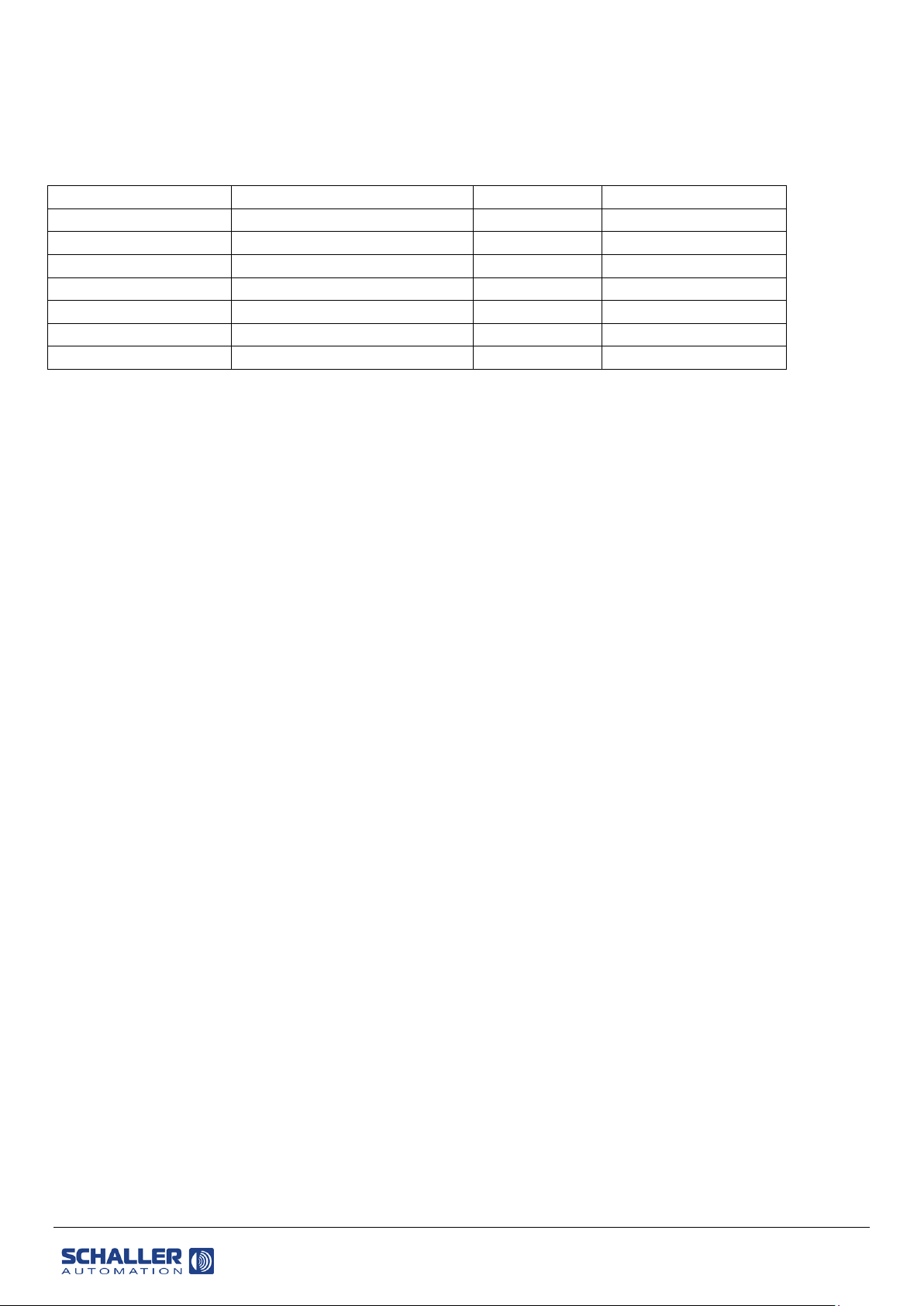

Table of contents

1Safety information/safety instructions ....................................................................................................6

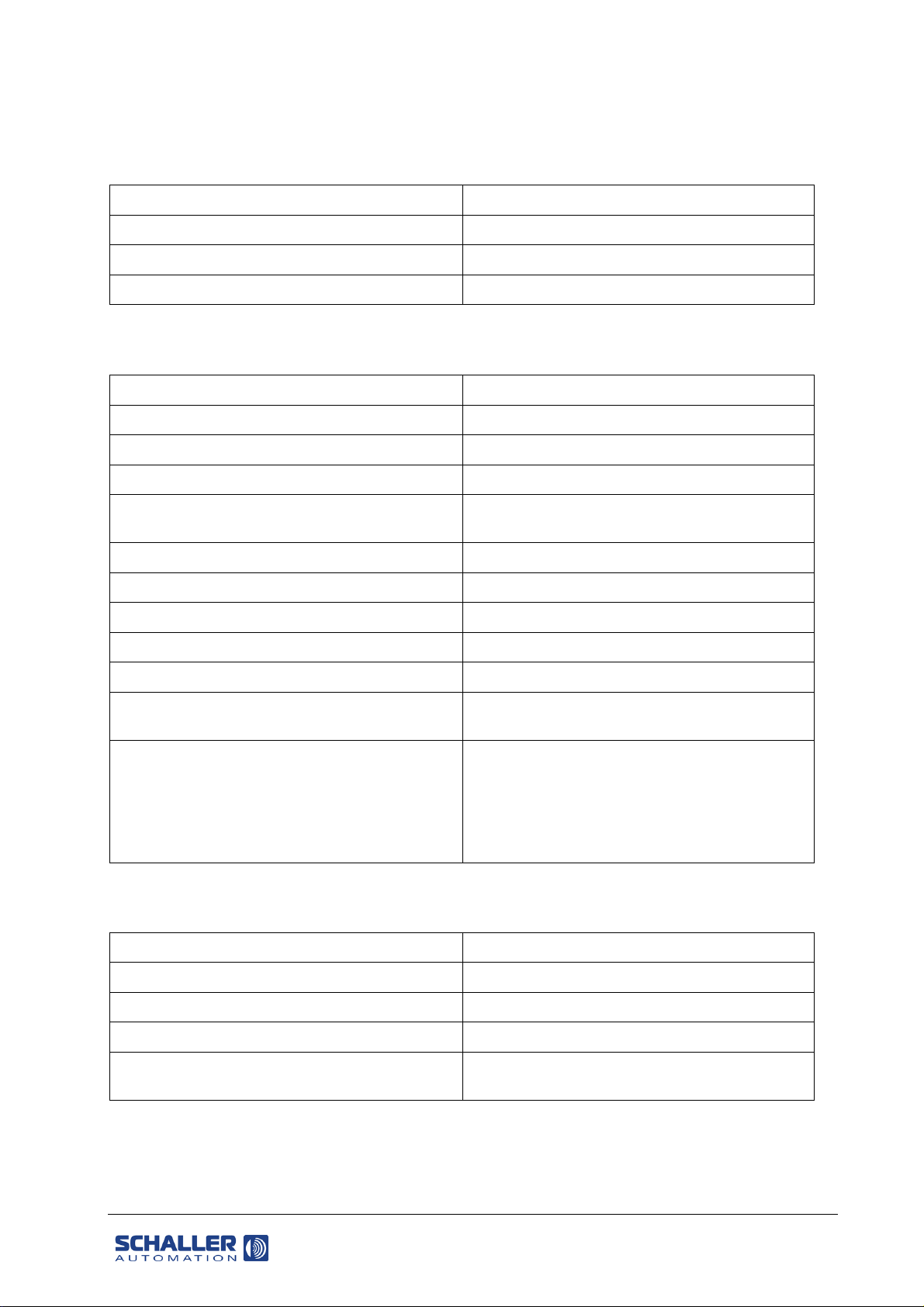

2Technical data.......................................................................................................................................7

2.1 Intended use .............................................................................................................................................. 8

2.2 Foreseeable misuse ................................................................................................................................... 8

2.3 Risk and safety declarations...................................................................................................................... 9

3Product description.............................................................................................................................10

4Installation and removal.......................................................................................................................11

4.1 Work and preparations to be completed by the customer ..................................................................... 11

4.2 Installing the sensor ................................................................................................................................. 11

4.3 Installing the sensor ................................................................................................................................. 12

4.3.1 Installing the shaft adapter: ...................................................................................................... 13

4.3.2 Installing the BEAROMOS 2020: .............................................................................................. 14

4.4 Electrical adaptation of the sensor .......................................................................................................... 16

4.5 Software installation................................................................................................................................. 16

4.5.1 System requirements................................................................................................................ 16

4.6 Removing the sensor ............................................................................................................................... 17

5Commissioning ...................................................................................................................................17

6Operation and application ...................................................................................................................17

6.1 Operation ................................................................................................................................................. 18

6.1.1 Main view.................................................................................................................................. 18

6.1.2 Chart view................................................................................................................................. 19

6.1.3 Parameter settings ................................................................................................................... 19

6.1.4 Log file and data storage.......................................................................................................... 20

6.1.5 RS485 log ................................................................................................................................. 20

6.2 Errors/malfunctions.................................................................................................................................. 22

7Maintenance and repair.......................................................................................................................22

7.1 Maintenance ............................................................................................................................................ 22

7.2 Repair....................................................................................................................................................... 23

8Packaging...........................................................................................................................................23

9Disposal..............................................................................................................................................24

10 Part numbers ......................................................................................................................................24

11 Spare parts catalogue .........................................................................................................................24

12 List of figures ......................................................................................................................................25

CONTACT .......................................................................................................................................................26