5

BRUSH CUTTER SAFETY

SITE PREPARATION AND CIRCUMSTANCES

• Evaluate the terrain to determine how to safely

perform the job� Only use accessories and

attachments approved by the manufacturer�

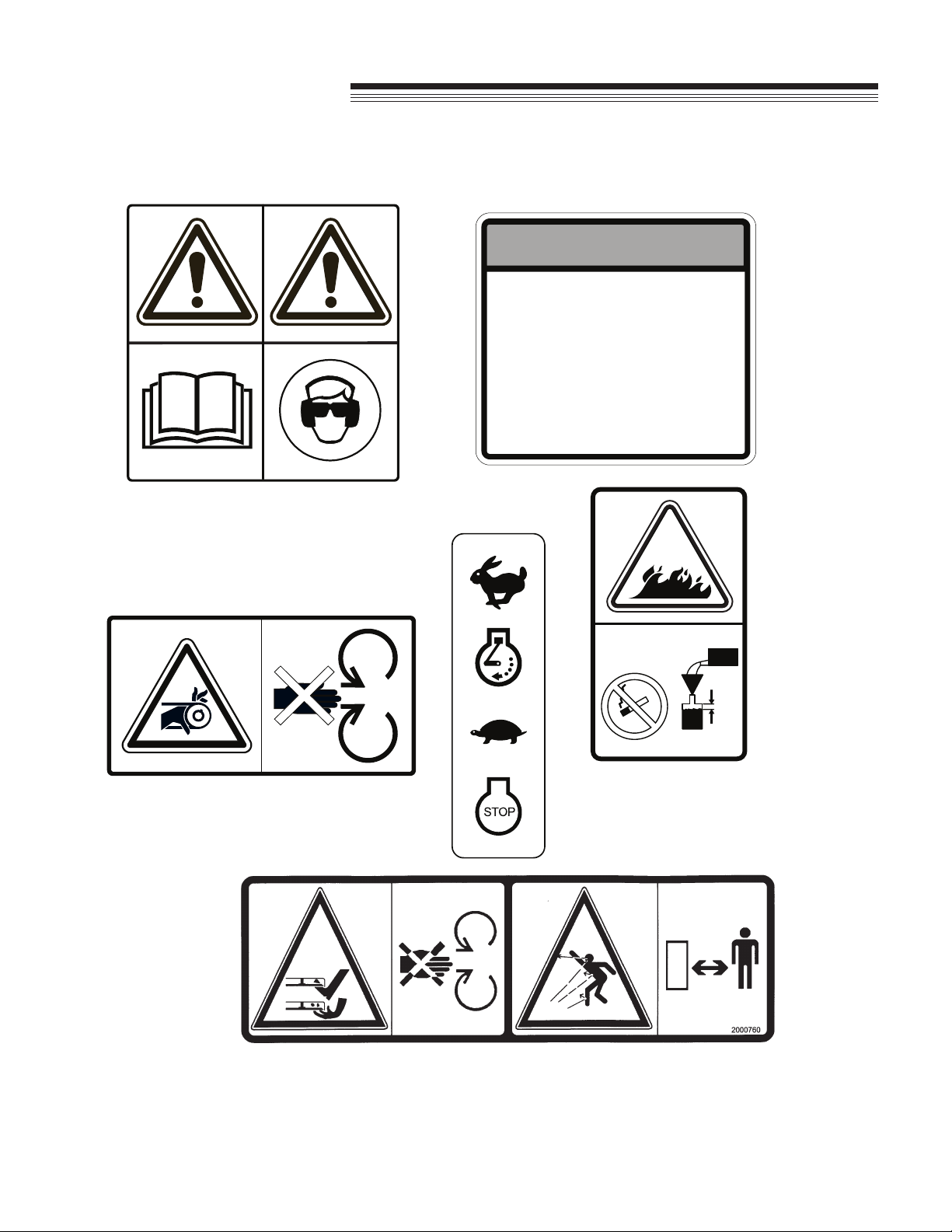

• Clear the area to be cut of objects such as rocks,

toys, wire or any other debris that may be thrown or

get tangled in the brush cutter�

• Be sure the area is clear of pets and people,

especially young children� Never assume they will

remain where you last saw them� Stop the machine

if any enter the area�

• Only cut in daylight or in good articial light.

• Keep in mind that the operator or user is respon-

sible for accidents or hazards occurring to other

people or their property�

• Do not cut wet grass as tires may lose traction�

OPERATOR PREPARATION AND

TRAINING

READ THE OPERATION &

SAFETY MANUAL

• If an operator or mechanic

cannot read English, it is

the owner's responsibility

to explain this material to them� If any portion

of this material is unclear, contact your factory

representative for clarication.

• Become familiar with the safe operation of the

equipment, operator controls and safety signs�

Be prepared to stop the engine quickly in an

emergency� Do not operate or allow another

person to operate this machine if there are any

questions about safety�

• All operators and mechanics should be trained� The

owner is responsible for training the users�

• Wear appropriate clothing, including safety goggles

or safety glasses with side shields when operating�

Wear substantial footwear and long pants� Do not

operate barefoot or wearing open sandals� Long

hair, loose clothing or jewelry may get tangled in

moving parts�

• Wear appropriate hearing protection�

• Wear safety glasses�

• Never allow children, unskilled or improperly trained

people to operate this equipment� Local regulations

can restrict the age of the operator�

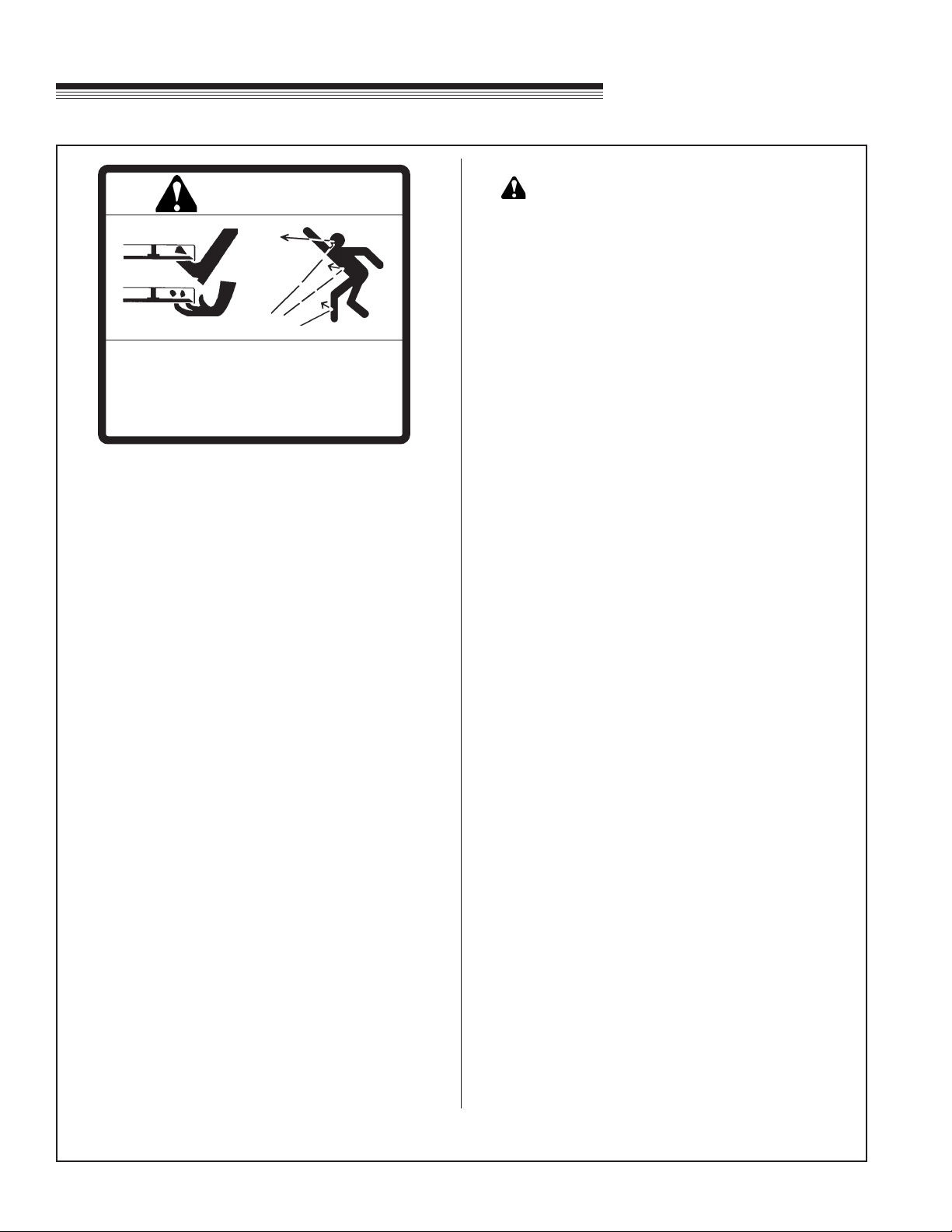

• Do not put hands or feet near or under rotating

parts� Keep clear of the front deck opening at all

times�

• Never pick up or carry the unit while the engine is

running�

• Keep warning labels and this operator’s manual

legible and intact� Replacement labels and manuals

are available from the factory�

• Do not operate machine while under the inuence

of drugs or alcohol, or any other condition of

impairment�

• The owner/user can prevent and is responsible for

accidents or injuries occurring to themselves, other

people, or property�

MULTIPLE OPERATORS

• Keep a safe distance between operators when

working together�

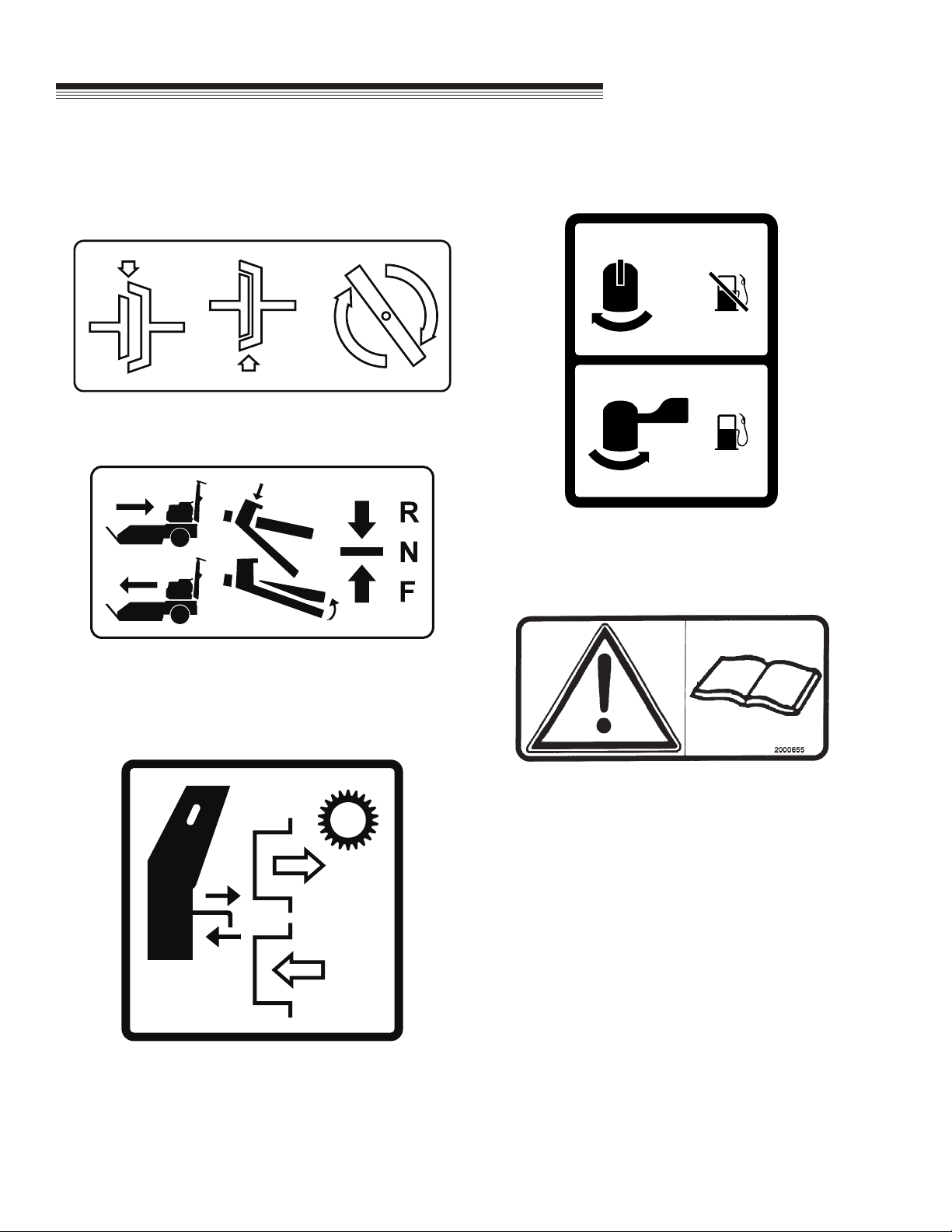

MACHINE PREPARATION

• Read engine manual�

• Check operator presence interlock system� Adjust

or have any problems repaired before using�

• Damage to the engine can occur if there is no oil or

oil level is low� Check the oil level and add oil per

engine manual as necessary�

• Do not tamper with or defeat safety devices� Keep

guards, shields and interlock safety devices in place

and in proper working condition� They are for your

protection�

• Keep all fasteners such as nuts, bolts, and pins well

secured�

• Visually inspect blades, blade bolts and the cutter

assembly for wear or damage� Replace worn or

damaged blades and bolts to preserve balance�

• Verify that machine and attachments, if any, are in

good operating condition�

• Do not engage blades until ready to mow�