6

Hydro

Midsize

j) Never operate the equipment in wet grass. Always

be sure of your footing; keep a rm hold on the

handle and walk; never run.

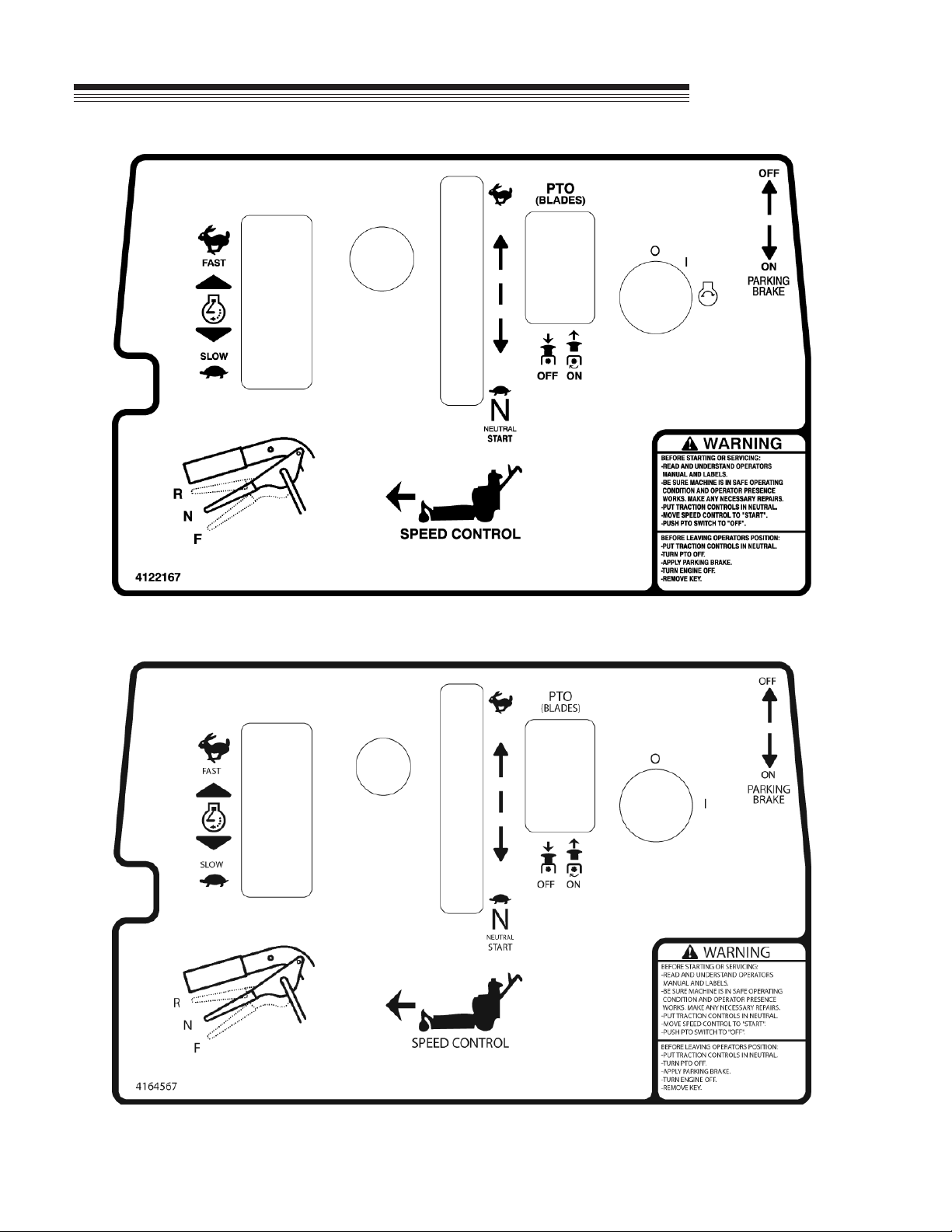

OPERATION

a) Do not operate the engine in a conned space where

dangerous carbon monoxide fumes can collect.

b) Mow only in daylight or in good articial light.

c) Always be sure of your footing on slopes.

d) Walk, never run.

e) With walk behind machines,mow across the slopes,

not up and down.

f) Exercise extreme caution when changing direction

on slopes.

g) Do not mow excessively steep slopes.

h) Use extreme caution when reversing or pulling the

mower towards you. Be sure the area behind is

clear.

i) Stop the blades if the mower has to be tilted for

transportation, when crossing surfaces other than

grass and when transporting the mower to and from

the area to be mowed.

j) Never operate the mower without proper guards,

plates, grass catcher or other safety protective

devices in place.

k) Do not change the engine governor settings or

overspeed the engine.

l) Disengage all blades and drive clutches before

starting the engine.

m) Start the engine carefully according to instructions

and with feet well away from the blades.

n) Do not start the engine when standing in front of

the discharge chute.

o) Do not put hands or feetnear or under rotating parts.

Keep clear of the discharge opening at all times.

p) Never pick up or carry a mower while the engine

is running.

q) Stop the engine, wait for the blades to come to

a complete stop, and disconnect the spark plug

wire:

• before clearing blockages or unclogging chute;

• before checking, cleaning or working on the

mower;

• after striking a foreign object. Inspect the mower

for damage and make repairs before restarting

and operating the mower;

• if mower starts to vibrate abnormally (check

immediately for the cause). Vibration is generally

a warning of trouble.

Before using machine for the rst time, check engine

and hydraulic uid levels and lubricate all points.

TRAINING

a) Read the operator’s manual carefully.Allrotary grass

cutters are potentially dangerous.No person should

operate the machine unless they are familiar with

the controls and the proper use of the machine.

b) Never allow children or people unfamiliar with these

instructions to use the mower. Local regulations

may restrict the age of the operator.

c) Keep the area of operation clear of all persons,

particularly small children and pets.

d) Keep in mind that the operator oruser is responsible

for accidents or hazards occurring to other people

or their property.

PREPARATION

a) Do not operate the equipment when barefoot or

wearing open sandals. Always wear substantial

footwear and long trousers.

b) Wear hearing protection.

c) Thoroughly inspect the area where the equipment

is to be used and remove rock, toys, wire or other

debris which may be picked up and thrown by the

machine.

d) Gasoline is highly ammable.

• Store gasoline only in a container specically

designed for gasoline storage in a cool, dry

place away from sparks and open ame.

• When refueling or checking fuel level:

• Stop engine. Allow to cool.

• Refuel outdoors only.

• Do not smoke.

• Use a funnel. Do not overll. Clean up spills

and move machine away from spills before

starting.

• Replace caps tightly.

e) Replace faulty mufers.

f) Before using, always visually inspect to see that

the blades, blade bolts and cutter assembly are

not worn or damaged. Replace worn or damaged

blades and bolts.

g) On multi-bladed machines, take care as rotating

one blade can cause other blades to rotate.

h) Disengage the self-propelled mechanism or drive

clutch on units so equipped before starting the

engine (motor).

i) Never attempt to make adjustmentswhile the engine

(motor) is running.

GENERAL INSTRUCTIONS