SECT | V1 | INSTALLATION MANUAL | 202102 2

SCHLETTER SOLAR GMBH | SUBJECT TO CHANGES

Table of contents

SECT INSTALLATION GUIDE ........................................................................................................... 3

TOOLS NEEDED ............................................................................................................................... 3

FURTHER REQUIRED DOCUMENTATION.................................................................................. 3

TIGHTENING TORQUE ................................................................................................................... 3

SAFETY INSTRUCTIONS................................................................................................................ 3

1. INTRODUCTION.......................................................................................................................... 4

1.1. Overview............................................................................................................................... 4

1.2. Compliance and certification .......................................................................................... 4

1.3. Orientation options............................................................................................................ 4

1.4. No reach’ installation ........................................................................................................ 5

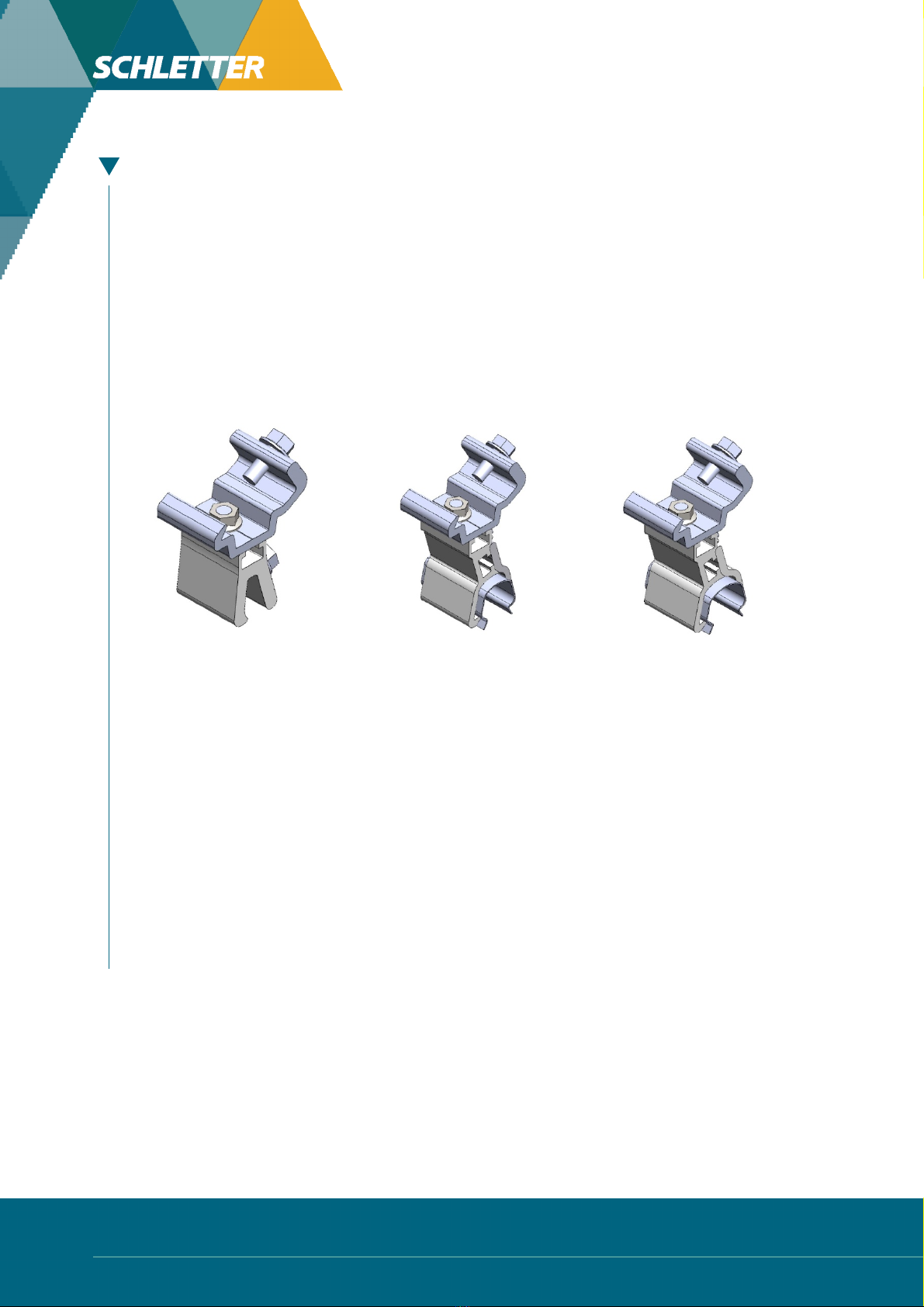

1.5. Types of roof fixings.......................................................................................................... 5

2. LAYOUT AND ASSEMBLY ......................................................................................................... 6

2.1. Fixing spacing ..................................................................................................................... 6

2.2. Length of column or row.................................................................................................. 6

2.3. Assembly .............................................................................................................................. 7

2.4. Joining channels ................................................................................................................. 9

2.5. Earthing................................................................................................................................. 9

3. INSTALLATION USING ROOF CLAMPS .............................................................................. 10

4. INSTALLATION USING ROOF SCREWS ............................................................................. 11

5. INSTALLATION USING CONCRETE ANCHORS ................................................................ 12

6. CABLE TRAYS............................................................................................................................ 12

6.1. Cable trays on a sheet metal roof .............................................................................. 12

6.2. Cable trays on a concrete roof..................................................................................... 13

6.3. Cable trays on another channel .................................................................................. 13

7. ELECTRICAL DESIGN CONSIDERATIONS......................................................................... 14

8. MAINTENANCE.......................................................................................................................... 14