4

GENERAL

1 GENERAL SAFETY INFORMATION

b Check that the product is complete, undamaged

and as ordered as soon as you receive it. Report

any discrepancies or damage to the dealer who

sold it.

b This product must be installed by a legally qualified

heating engineer. On completion of the installation,

the installer must issue the owner with a declara-

tion of conformity confirming that the installation has

been completed to the highest standards in com-

pliance with the instructions provided by Bin

this instruction manual, and that it conforms to all

applicable laws and standards.

b This product must only be used for the purpose

for which it is designed and made, as specified by

B. Bdeclines all responsibility, contractual

or other, for damage to property or injury to persons

or animals caused by improper installation, adjust-

ment, maintenance or use.

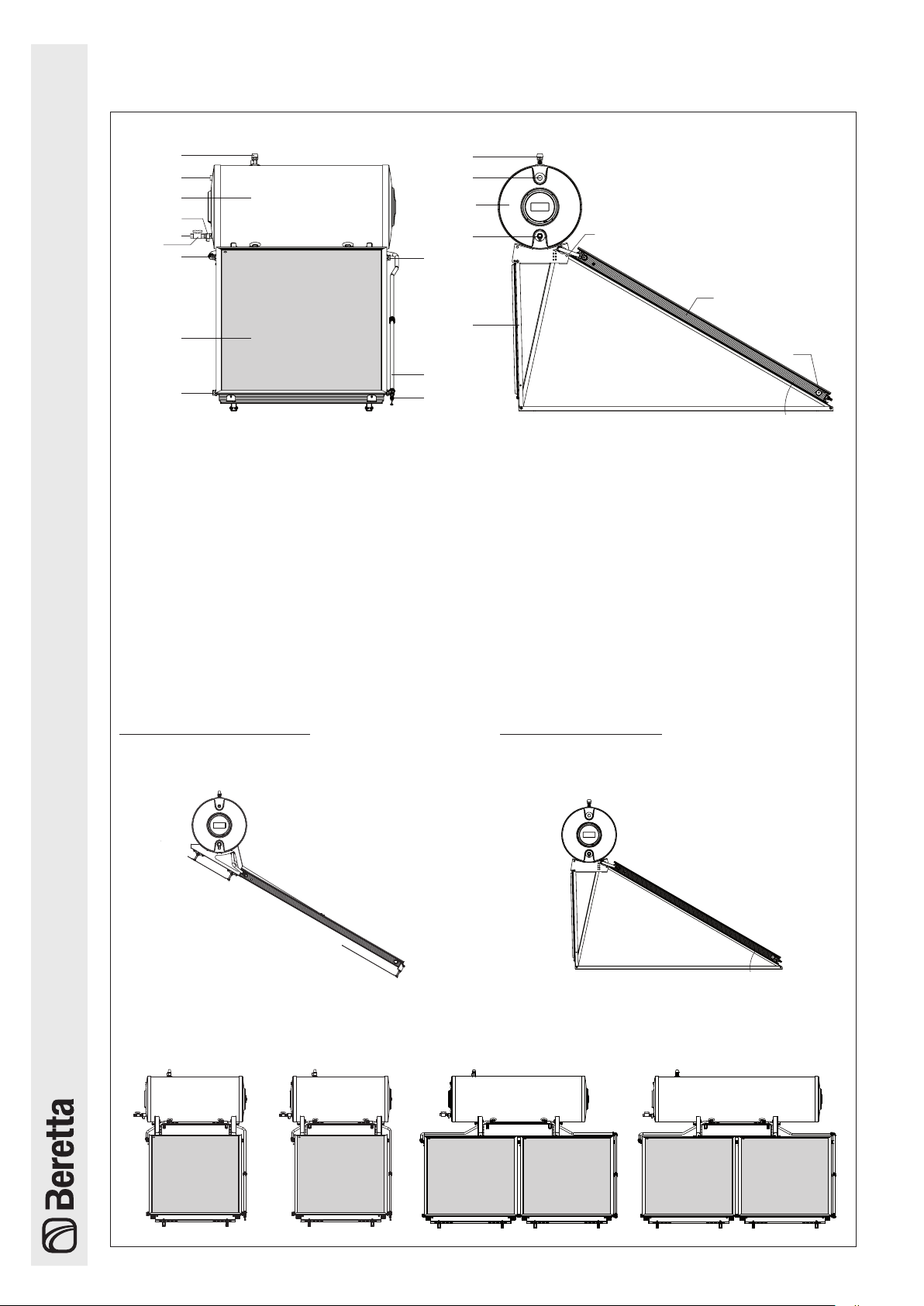

b Make sure that the roof is strong enough to support

the weight of the solar water heating system under

operating conditions. Also make sure that the sec-

tion of roof chosen for the installation enjoys a high

level of insolation, and is not shaded during the day

by tall plants, trees, other houses, hills, etc..

b The installation of a solar water heating system

modifies the existing structure of the roof. Verify

the suitability of all roof elements and if necessary

adapt them to avoid leaks or damage by wind and/

or snow loads.

b If the system is installed in an area subject to gust-

ing winds or snow loads in excess of the limits given

in the technical specifications, consult your supplier

for advice.

b Snow can build up in the sheltered area behind

the solar water heating system. Provide adequate

protection to avoid increasing the static load on the

roof.

b The system must be serviced at least once a year.

b The water supply circuit must permit the storage

cylinder to be filled and emptied in safety. Shut-off

valves must therefore be easily accessible to the

user and the operation of emptying the storage cyl-

inder must not create any risk of flooding or other

damage.

b Insulate the domestic water pipes (hot and cold)

and the pipes of the solar collector circuit. Provide

suitable insulation for all outdoor accessories.

b The point through which the water pipes enter the

building must be rain-proof and damp-proof.

b If you notice any water or heat transfer liquid leaks,

disconnect the system immediately from the mains

electricity supply (if a supplementary heating ele-

ment is installed), shut off the water supply, and no-

tify B’s Technical Assistance Service or a quali-

fied heating engineer immediately.

b Make sure that the water-glycol mix in the solar col-

lector circuit is able to resist the minimum tempera-

tures likely to occur in the place of installation.

b The system can reach very high temperatures. Safe-

ty valves can therefore discharge extremely hot liq-

uids. Make sure that the expansion vessel is of a

suitable size and design for use in solar water heat-

ing systems.

b Use proper slings to lift and move the elements of

the system. Never lift the collector or storage cylin-

der by their fittings. Avoid subjecting the collector

to impacts or mechanical strain, and take care to

protect the glass panel. Use the personal protection

equipment required by applicable safety standards.

2 PRECAUTIONS

a Never attempt to install the system without using the

personal protection equipment and without follow-

ing the safety precautions specified by applicable

occupational safety standards.

a Never install solar collectors on roofs without an ad-

equate lightning protection system.

a Never install the system without providing proper

drainage for the two safety valves: that of the do-

mestic hot water circuit and that of the primary (so-

lar collector) circuit.

a If the storage cylinder is equipped with a supple-

mentary heating element, never attempt any clean-

ing or maintenance without first disconnecting it

from the mains power supply.

a Do not allow children or infirm persons to operate

the system unsupervised.

a Do not tamper with or adjust the safety or control

devices without prior authorisation and instructions

from the manufacturer.

a Never use anti-freeze other than that supplied by

Bto fill or top up the solar collector circuit. Mix-

ing different products can reduce the anti-freeze

protection provided.

a Never drain the solar collector circuit under sunny

conditions or when the collector is hot.

a Do not dispose of packaging material into the en-

vironment, or leave it within the reach of children,

since it can become a potential hazard. Dispose of

packaging material in compliance with applicable

legislation.

General