Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany 9

Pump type S / SF

Version: 27229 - E

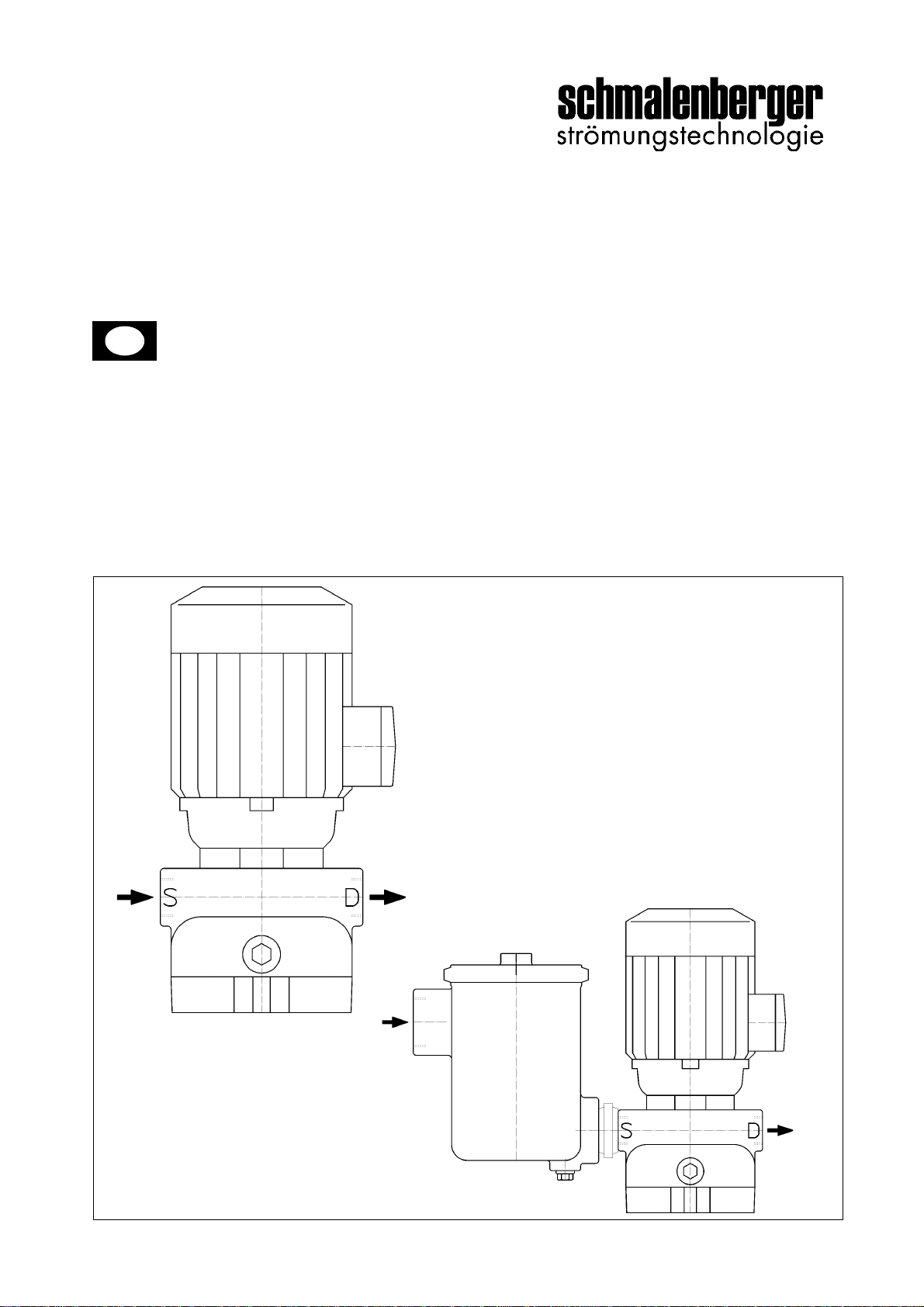

When installed on a foundation the centrifugal

pump must be set up with the aid of a spirit level.

2.3.4 Connecting the pipework

Note the denomination on the housing:

S = suction connection, D = pressure

connection

The pipes must be supported as close as

possible to the centrifugal pump and connected

to it free of all tension. Their weight must not be

supported by the pump.

The positioning must be undertaken with the

greatest care as this is the prerequisite for

trouble-free operation of the plant.

If these instructions are not observed,

then any claims under guarantee will be

void.

• If the pipe strength is exceeded leaks can

occur in the pump or in the flange

connections, for example, that could result in

vast amounts of medium being expelled.

• In the case of short pipes the nominal bore

should be at least the same as the

centrifugal pump connections. For long

pipes the most economic nominal bore

should be determined on a case by case

basis.

• Connection pieces to larger nominal bores

should be carried out with approx. 8°

expansion angle to avoid significant loss of

pressure.

• In order to prevent the formation of air

pockets, the suction pipe to the centrifugal

pump must be installed to rise continuously,

on the pressure side it must fall continuously.

Depending on the type of system and

centrifugal pump being used, it is

recommended that backflow prevention and

shut-off devices are installed.

• Often welding beads, scales and other

impurities do not get dislodged for some

period of time. They should be kept clear of

the pump by inserting a sieve in the suction

pipe.

• The free cross-section of the sieve must be

3 times the cross-section of the pipe so that

there is not too large a resistance built up

due to foreign bodies that flow in.

Hat-shaped sieves containing a mesh wire net

having a mesh size of 2.0 mm and

0.5 mm wire diameter made of corrosion

resistant material have proved useful in practice.

2.3.5 Electrical connections

The electrical connections to the pump must be

carried out by a specialised company in the

electrical engineering branch approved by the

local energy provider, taking into account the

technical connection requirements.

Positioning them with the

motor hanging downwards is

not permitted.

Warning!

Under no circumstances must

the pump be used as anchor

point for the pipework. No

forces or moments (e.g. due to

twisting or heat expansion)

from the pipework must act on

the pump.

Important

Pipe compensators must not be

used to make up for inaccuracies in

the pipelines, for example with a

centre offset of the flange.

Warning!

In the case of hot, caustic or

poisonous delivery media!

Warning! Mortal danger!

Taps that close very suddenly

(abruptly) must be avoided in the

pipework. The resulting pressure

surges can greatly exceed the

maximum permitted housing

pressure of the pump!

To prevent too strong pressure

surges dampers or blast tanks

should be installed.

Note:

At the end of installation, before

starting up the system the tanks,

pipes and connections must be

thoroughly cleaned, rinsed and

blown through.