Schmalenberger GmbH + Co. KG

D-72072 Tübingen / Germany

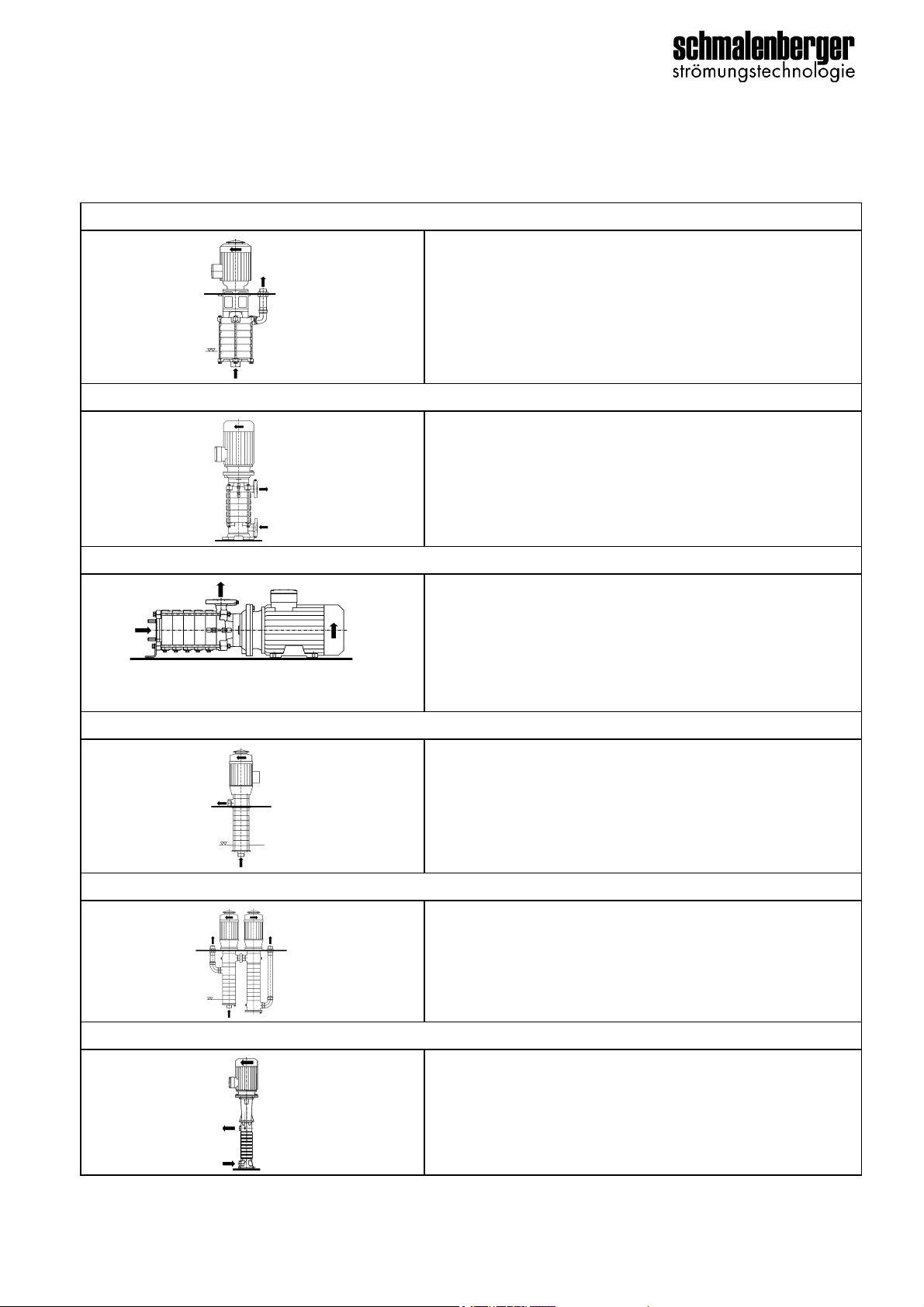

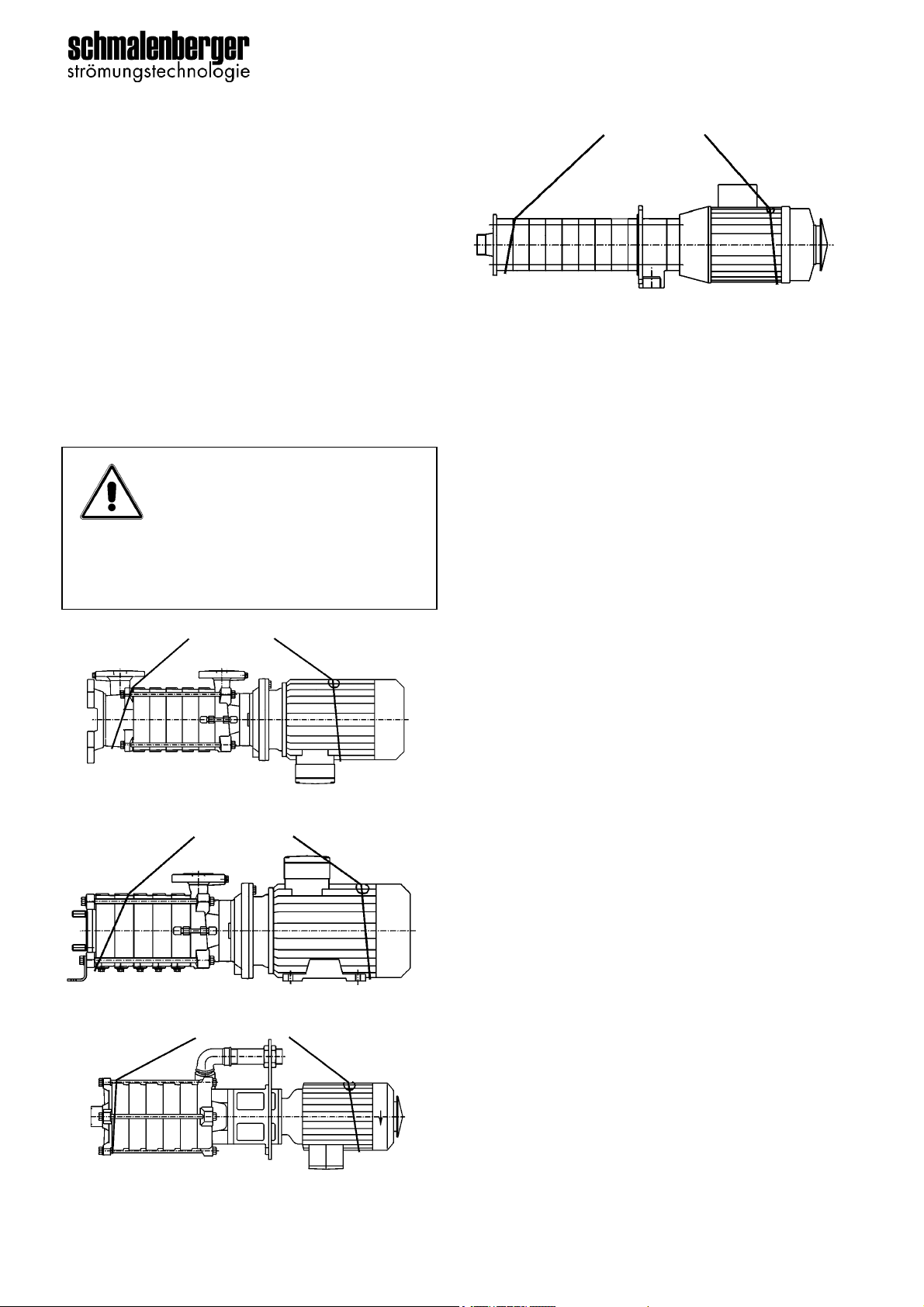

Pump Typ ZH- / TH- / DUO

Version: 27224 - E 5

1 General Details

1.1 User Information

This operator’s manual makes it easier to get to

know the centrifugal pump and to make full use

of its facilities.

The operator’s manual contains important in-

structions how to use the centrifugal pump safe-

ly, properly and economically. Your careful

attention to these instructions will help to avoid

danger, to reduce repair costs and breakdowns

and to increase the reliability and useful life of

the centrifugal pump.

The operator’s manual does not take account of

local regulations. The user is responsible for en-

suring that they are complied with.

The label specifies the machine series, the frame

size, the most important operating data and the

serial number. We request that you always quote

it in case of queries, when placing subsequent

orders and especially when ordering spare parts.

1.2 Usage Instructions

The centrifugal pump must only be used in ac-

cordance with the original pump specifications

and the operator´s manual. Any other usage or

operation where these figures are exceeded is

not permitted. The manufacturer is not liable for

damage resulting from such improper use.

The pump must only be operated in applications

that are described in the relevant documents.

• The pump must only be operated if it is in

flawless technical condition.

• The pump must not be operated if it is only

partially mounted.

• The pump may only be used to convey the

media described in the data sheet or in the

documentation for the relevant design.

• Never operate the pump without a pumping

medium.

• Pay careful attention to the information in the

data sheet or documentation regarding min-

imum delivery volume (to prevent damage

from overheating, damage to the bearings,

etc.).

• Pay careful attention to the information in the

data sheet or documentation regarding max-

imum delivery volume (to prevent overheat-

ing, damage to the mechanical seal,

cavitation damage, damage to the bearings,

etc.).

• Do not throttle the pump on the suction end

(to prevent cavitation damage).

• Coordinate other types of operation with the

manufacturer if they are not cited in the doc-

umentation or data sheet.

Preventing foreseeable misuse

• Never open the pressure-end shut-off ele-

ments beyond the permissible range

- Exceeding the maximum delivery volume

cited in the data sheet or documentation is

not permitted (possible cavitation damage)

• Never exceed the permissible operating lim-

its cited in the data sheet or documentation

in terms of pressure and temperature, etc.

• Comply with all safety instructions and direc-

tions in this operator's manual.

1.3 Relevant Documentation

Various documents are associated with every

centrifugal pump that comprise the technical

documentation of the pump. These are as fol-

lows:

• Operator’s manual

• Drive operator’s manual

• Manual for accessories listed in the specifi-

cations manual

• Acceptance report from the TÜV (Technical

Certification Authority) etc.

• Pilot run report

• Performance run report

• Installation drawing (dimensions sheet)

• Declaration of conformity with supplement

BA for ATEX pumps

• Declaration of conformity / Declaration of In-

corporation

• Specification with all data

Not all the above documentation has been pro-

duced and supplied in every case. For this

please check the details in the specification.

1.4 Technical Data / Specifications

The specifications of the centrifugal pump is the

most important document in every operator’s

manual. Contained therein are all the relevant

and technical data relating to the centrifugal

pump. It is the birth certificate of the centrifugal

pump and should be treated accordingly.