Instructions for Use SS 20.200 Page 8

6 Switching threshold

The switching output will trip at an adjustable flow velocity. There are two

basic types of setting the switching threshold:

Manual setting (order code L = P)

The switching threshold is set using the potentiometer mounted on the

front side of the SS 20.200. To increase the switching threshold, rotate

the potentiometer clockwise and visa-versa. The measuring range of the

sensor is correlated linearly with the 270 degrees of rotating, i.e., at the

upper end (clockwise) the switching threshold is 95 % of the measuring

range. At the lower end (zero point) the switching threshold is limited to

5 % of the measuring range.

With order code xx = 00, the potentiometer is set at about 50% (default).

At a distinct value xx > 00, the potentiometer is set ex works to the de-

sired switching threshold („xx“ % of measuring range).

The individual setting of the switching point is done by adjusting the flow

velocity to the desired threshold value. Then the potentiometer is rotated

from the zero point clockwise until the relay is switching. The release

point is then offset downward by the hysteresis (see also chapter: Hyste-

resis of switching threshold). For fine adjustment, the potentiometer can

now be rotated back a little bit.

Preprogramed switching threshold (order code L = F)

If the flow velocity to be monitored is already known at the time of order-

ing, the sensor can be ordered with a fixed, preprogramed switching

threshold. In this case, the potentiometer is put out of action and a stick-

er on the front side of the sensor informs about the programmed switch-

ing threshold.

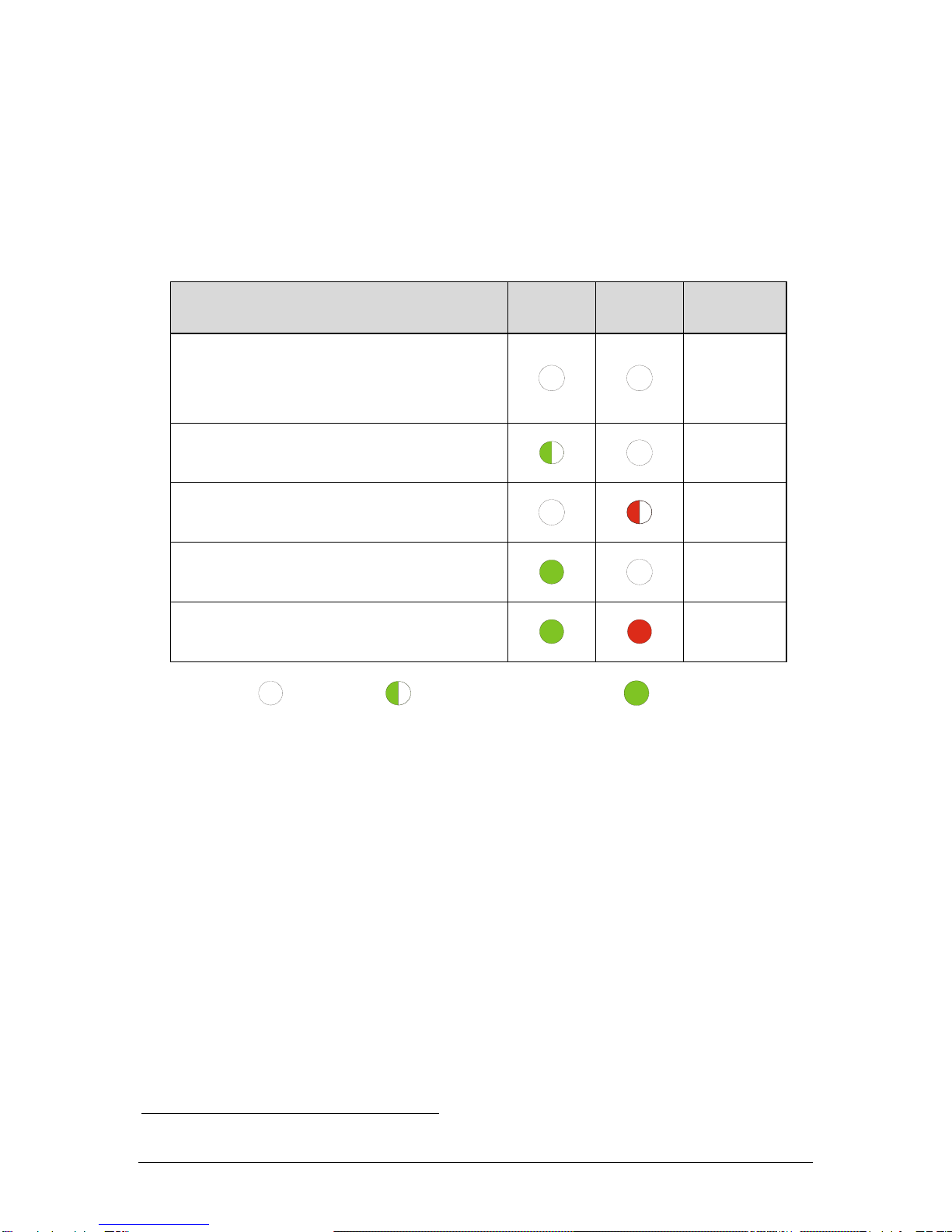

Hysteresis of switching threshold

The hysteresis of the switching threshold is defined as the value that

separates the switching point (SP) from the release point (RP). It is im-

portant which switching logic (S) was selected.

For S = 1 and S = 2, the sensor switches directly at the defined SP. RP

is lower by 5 % of the measuring range.

For S = 3 and S = 4, SP is 5 % above the preset value. In this case, RP

coincides exactly with the preset value.