AR100 Operation Manual

© 2018 Schmitt Industries Revision 1.1

Table of Contents

Safety Precautions..............................................................................................4

CE compliance....................................................................................................4

Laser safety.........................................................................................................4

General information............................................................................................4

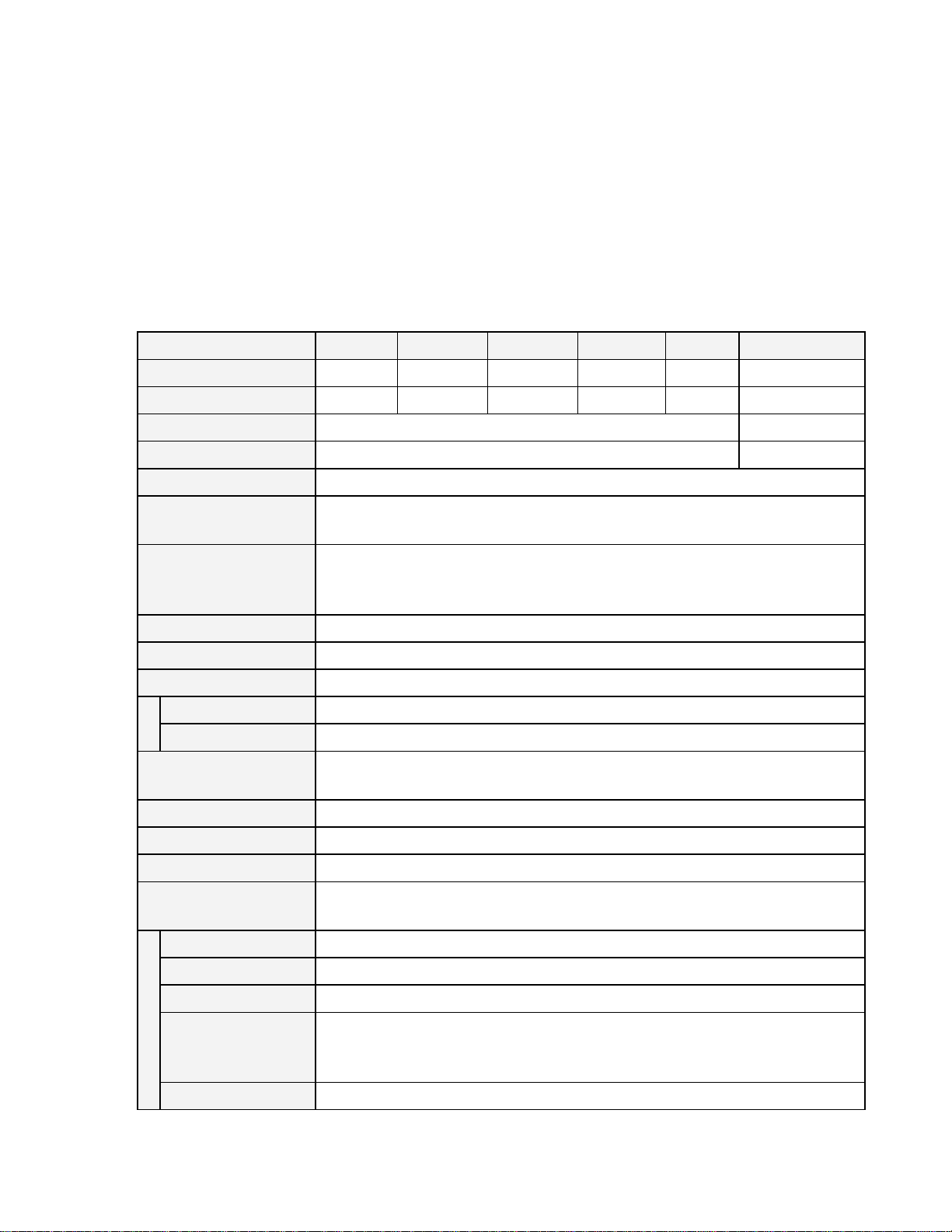

Basic technical data ...........................................................................................5

Options to designate when ordering the AR100..............................................6

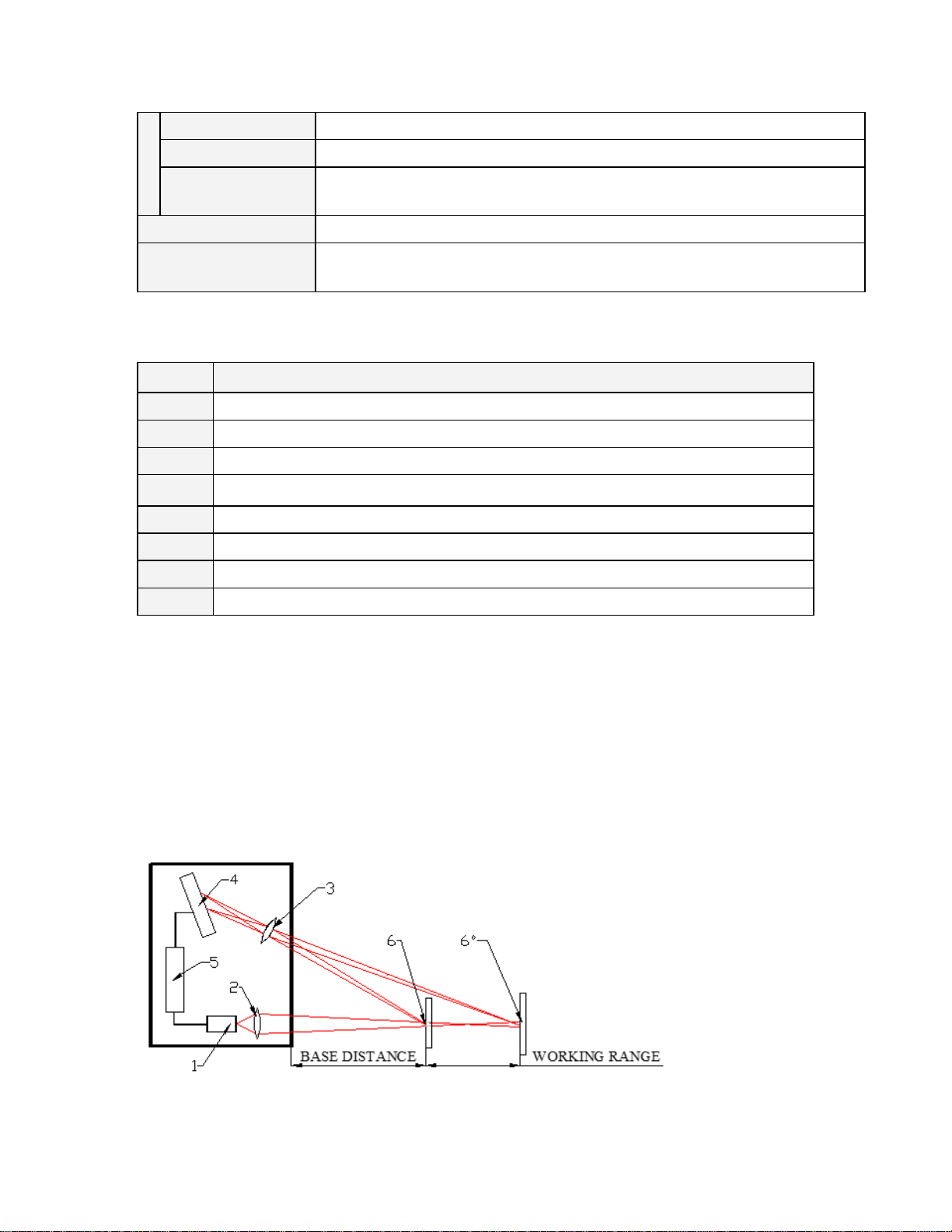

Structure and operational principle ..................................................................6

Dimensions and mounting.................................................................................7

Overall and mounting dimensions...........................................................................7

Overall demands for mounting.................................................................................7

Connection..........................................................................................................8

Configuration parameters..................................................................................8

Time limit for integration ..........................................................................................8

Sampling mode..........................................................................................................9

Sampling period ........................................................................................................9

Zero point.................................................................................................................10

Line AL operation mode .........................................................................................10

Time lock of the result ............................................................................................12

Method of results averaging...................................................................................12

Number of averaged values/time of averaging......................................................12

Factory parameters table........................................................................................12

Description of RS232 and RS485 interfaces...................................................13

RS232 port...............................................................................................................13

RS485 port...............................................................................................................13

Serial data transmission format.............................................................................13

Modes of data transfer............................................................................................13

Communication sessions types.............................................................................13

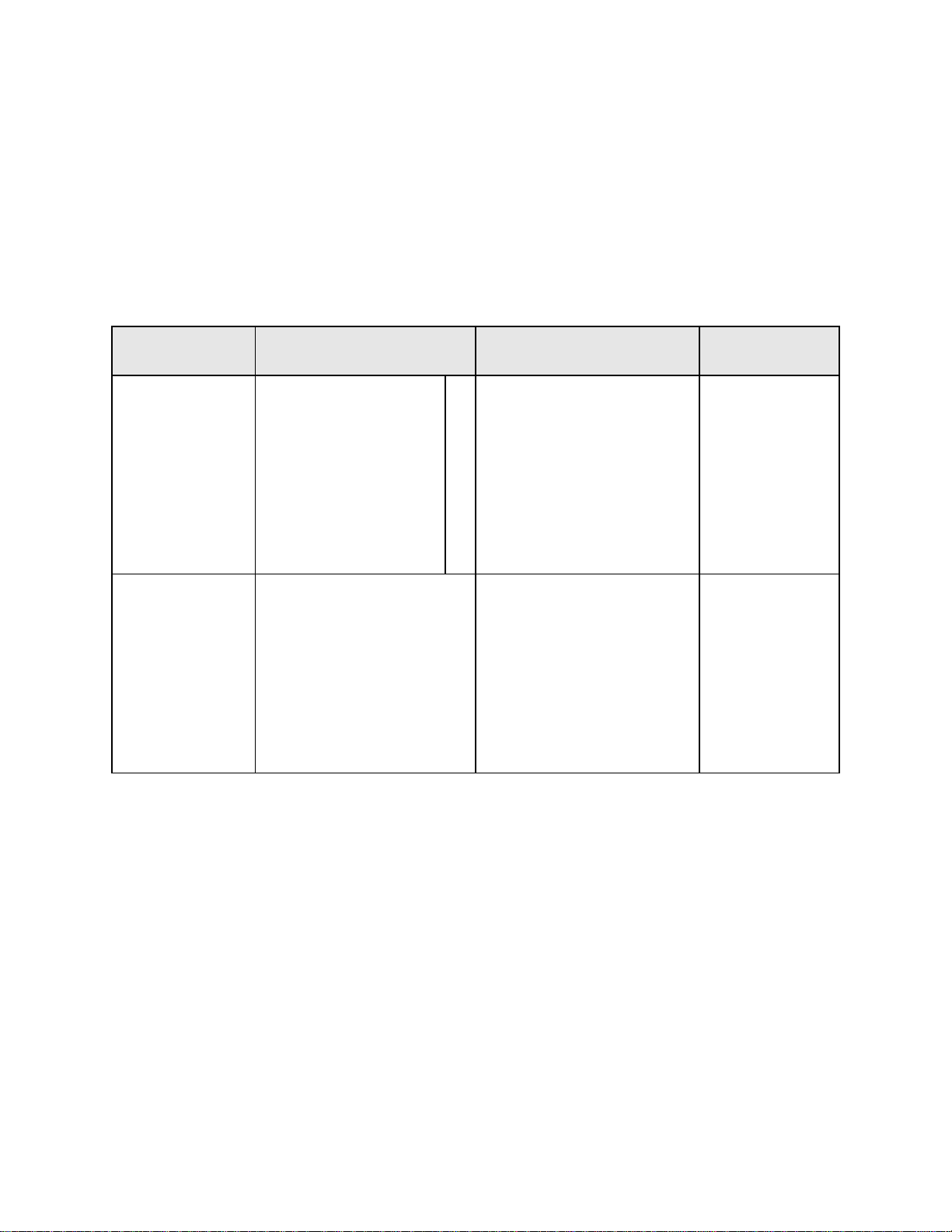

Configuration parameters.......................................................................................14

Rate of data transfer through serial port ................................................................14

Net address...........................................................................................................14

Factory parameters table.......................................................................................14

Acuity protocol (binary format)..............................................................................14

Request.................................................................................................................14

Answer ..................................................................................................................15

Data stream...........................................................................................................16

Output rate............................................................................................................16

Request code table................................................................................................16

Notes.....................................................................................................................18

Modbus RTU protocol (binary format)...................................................................22

Input Registers (Read only)...................................................................................22

Holding Registers (Read / Write)...........................................................................22

ASCII format ............................................................................................................23