Schwank MonsterFan Series Operating and maintenance manual

www.monsterfans.com info@monsterfans.com 2

Table of content:

1 Introduction .............................................................................................................. 3

1.1 Specifications........................................................................................................ 3

2 Safety Instructions..................................................................................................... 3

2.1 Placement & Distances........................................................................................ 4

2.2 Checklist ................................................................................................................ 5

3 Parts Overview MonsterFans ................................................................................... 6

3.1 Bill of Materials ...................................................................................................... 6

3.2 Required Tools....................................................................................................... 8

4 Installation & Mounting............................................................................................ 8

4.1 Safety Clearances................................................................................................ 8

4.2 Safety Distances to Ventilation Systems ............................................................. 9

4.3 Required Installation Environment....................................................................... 9

4.4 Mounting Sets ..................................................................................................... 10

4.5 Extension Elements ............................................................................................. 11

4.6 Wire rope clamps & Thimbles ............................................................................ 11

4.7 Installation of MonsterFans................................................................................. 12

4.8 Electric Connections .......................................................................................... 14

4.9 Oil Check and Oil Safety Pin.............................................................................. 15

5 Frequency Inverter................................................................................................. 16

6 Commissioning ....................................................................................................... 17

6.1 Test Run................................................................................................................ 17

6.2 Warnings.............................................................................................................. 17

6.3 Troubleshooting .................................................................................................. 17

6.4 Frequency Inverter Error Messages ................................................................... 18

7 Warranty & Maintenance ..................................................................................... 19

8 Packaging Units...................................................................................................... 20

9 Acceptance Report for Installation & Commissioning........................................ 21

10 Acceptance Report of Maintenance.................................................................. 22

11 Declaration of Conformity .................................................................................... 23

MonsterFans Assembly Video:

www.monsterfans.com info@monsterfans.com 3

1Introduction

Congratulations on your MonsterFan purchase.

The High Volume, Low Speed fans (HVLS) of the MonsterFans series are energy-saving units

with high comfort and diameters from 3.6 m (12ft.) to 7.3 m (24 ft.). They move big amounts

of air at low rotational speed. The blades are streamlined and ideally engineered according

to the principles of aerodynamics.

With a power rating of 1.5 kW, the aluminium blades can move large air masses over a large

area and create a comfortable breeze. MonsterFans cool by lowering the ambient

temperature. In winter MonsterFans can effectively be used for destratification. Please also

note the warning notices for destratification.

1.1 Specifications

Diameter

3.6 m (12 ft)

4.9 m (16 ft)

6.1 m (20 ft)

7.3 m (24 ft)

Article no.

195 80 200

195 80 204

on request

195 80 212

Type

MF-C12

MF-C16

MF-C20

MF-C24

Max. Air Volume

621,000

m3/h

675,000

m3/h

729,000

m3/h

783,000

m3/h

Rounds per Minute

10-95 RPM

10-75 RPM

10-65 RPM

10-55 RPM

Weight*

104 kg

113 kg

124 kg

132 kg

Motor Power

1.5 kW / 2 hp

Max. Electrical

Consumption

3.23 A

3.23 A

3.23 A

3.23 A

Supply Voltage

3~400 V, 50 Hz

Max. Coverage Range

630 m2

850 m2

1.380 m2

1.800 m2

Recommended Range

150 - 400 m2

250 - 550 m2

400 –800 m2

500 –1200 m2

Sound Pressure Level

55 dB

measured at max. rotational speed at 5 m distance

*Notes: The weight specifications refer to the fan without controller and without mounting set or

further extension tube.

2Safety Instructions

Read these use instructions carefully before starting the fan. Clear the operating

area of the fan from all obstacles to have enough space for the fan.

Before installation and maintenance work on the fan, ensure that the power

supply is disconnected.

Ensure that all safety precautions and instructions are followed when installing,

operating and maintaining the fan. Failures caused by disregarding these safety

precautions can result in serious injury or death. If you do not understand the

instructions, please contact your customer service.

Installation, power supply, commissioning, maintenance and repairs may only be

carried out by a qualified specialists who are familiar with national and local

guidelines for electrical installations and building regulations.

www.monsterfans.com info@monsterfans.com 4

All electrical components are pre-programmed at the factory and ready for use.

Follow these installation instructions during installation. Please do not make any

changes to components. Install the device completely before putting the device

into operation.

To avoid the risk of electric shock, note the following:

a) Use this device only as intended by the manufacturer. If you have any

questions, please contact the manufacturer or your local service partner.

b) Always disconnect the unit from the power before maintenance or cleaning

work.

The mounting of the suspension elements must be carried out by a qualified

specialist. The fan´s wings have to be installed at least 3.5 m above the floor.

Do not operate or install a big fan or individual parts that are damaged. If the fan

does not work properly or if there are any unusual movements of the fan, switch

off the power supply and contact your customer service.

Make sure that the replacement of in particular safety-related parts, is carried out

by the manufacturer, its customer service or a qualified specialist.

Install the safety cables on each fan according to the installation instructions. The

MonsterFans must never be operated without a properly installed safety cable. In

an emergency, the safety ropes additionally secure the fan. Proper installation of

the ropes is also required for the stabilisation during operation. The fan shall not be

operated in windy surroundings.

We recommend also securing the floor under the assembly so that attention is

drawn to the work on the ceiling. Review all relevant guidelines to ensure that

building regulations are followed in accordance with product certifications.

We always recommend having a structural engineer check who confirms the

strength of the building and ceiling structure in advance.

If MonsterFans are located in closed rooms with heaters with indirect exhaust gas

systems (unflued), the parallel operation must be prevented by interlocking it!

2.1 Placement & Distances

Before installing the fans, check compliance with all guidelines for fire alarm systems, sprinkler

systems and fans. We strongly recommend consultation with your local safety expert.

If sprinkler systems are installed, the fans must not interfere with the proper operation of these

sprinklers. The control unit can also be connected to a fire alarm system so that the fan stops

in an emergency.

The digital inputs and the Modbus interface of the control units are used for switching off and

interlocking. If possible, do not mount the fan directly under lights to avoid adverse lighting

effects from rotating wings.

If the building has a mezzanine, fans should be installed in the way that they are not

accessible to people. HVLS fans should not be installed in the immediate vicinity of air supply

outlets or suction inlets of other heating, ventilation, or air conditioning units, see chapter 4.2.

www.monsterfans.com info@monsterfans.com 5

2.2 Checklist

☐Do you have the right mounting set for your mounting position?

The standard mounting set supplied with this fan for I-beam, allows the fan to be hung on

steel beams. Do not mount the fan on a purlin or a framework.

If you are unsure, please contact customer service.

☐Has a structural engineer checked and approved the assembly position?

The assembly structure must withstand the forces generated by the fan.

☐The fan is NOT used in parallel with heaters with indirect exhaust gas systems (unflued).

Otherwise, parallel operation must be prevented by interlocking it.

☐The fan is at a minimum distance from the ceiling in accordance with the specified safety

distances.

☐The fan´s wings are installed at least 3.5 m above the floor.

☐The fan is installed with a minimum distance of 2 times the fan diameter from obstacles and

building structure, measured from the fan centre.

☐The distance between several fans is at least 2.5 times the fan diameter, measured from

the fan centre.

☐The fan is installed that it is not exposed to strong winds and maintains a safety distance of

at least 1 times the fan diameter from other heating, ventilation, air conditioning systems or

from gates.

☐The supply voltage is selected correctly.

☐The fan can be secured with the supplied safety ropes

There are mounting points available for the safety ropes.

If your fan application does not meet the above requirements, proper operation is at risk.

Please contact your customer service.

www.monsterfans.com info@monsterfans.com 6

3Parts Overview MonsterFans

1. Steel structure

2. Safety rope ring

3. Steel structure fastening

4. Extension tube

5. Motor housing

6. Winglets of fan blades

7. Fan blades

8. Turnbuckle & clamps

9. Safety steel rope

10. I-type safety adapting piece

3.1 Bill of Materials

www.monsterfans.com info@monsterfans.com 7

Bill of Materials - MonsterFans

1. Motor Housing 2. Top-Plate 3. Spacer 4. Beam clip

2x 2x

5. Turnbuckle 4x 6. I-type fan 7. Fastener M5 x 12 mm 8. Bottom plate

& 1x replacement blade retainer 5x 3x

9. Safety steel rope 10. Steel wire lock 11. Fastener 12. Fastener

40m length 55x M12 x 80 mm M16 x 55 mm

10x 4x

13. Fastener 14. Metal joint on 15. Controller Box 16. Techn. Manual

M16 x 120 mm Controller Box MonsterFans

4x 2x

17. Techn. Manual 18. Fan blades 19. Extension Tube 20. 3-Pole switch-

Danfoss VFD 5x 1m length disconnector

21. Thimbles

16x

www.monsterfans.com info@monsterfans.com 8

3.2 Required Tools

Spanner Set

Socket Wrench

Set

Screwdriver

Cross & Slot

Spirit Level

Wire rope

shear

Cable Shears

Wire Stripper

Multimeter

Distance Meter

Threadlocker

Glue

Please also note the necessary safety precautions for the use of a scissor lift and the general

safety precautions. Two specialists are required for the installation.

4Installation & Mounting

4.1 Safety Clearances

www.monsterfans.com info@monsterfans.com 9

4.2 Safety Distances to Ventilation Systems

If the air supply outlet of a ventilation system is below the blades, a minimum distance of 1

times or larger the fan diameter from the blade tip is sufficient.

If the air supply outlet of a ventilation system is located above the blades, a minimum

distance of 2 times or larger the fan diameter from the blade tip is necessary.

4.3 Required Installation Environment

Installation Environment

Conditions

Installation Location

Inside

Temperature Range

-15 + 55 °C

Do not use the product in environments with strong temperature

fluctuations.

The product must not be exposed to frost.

Humiditiy

Below 95% relative humidity

Surrounding

The fan and controller must not be exposed to flammable or

corrosive gases. Metal powder, oils, water and other foreign

objects must not get into the controller.

Distances to hot sources e.g. heaters must be maintained. Please

note the manufacturer's safety clearances.

If MonsterFans are located in closed rooms with heaters with

indirect flue gas systems (unflued), parallel operation must be

prevented by interlocking it.

www.monsterfans.com info@monsterfans.com 10

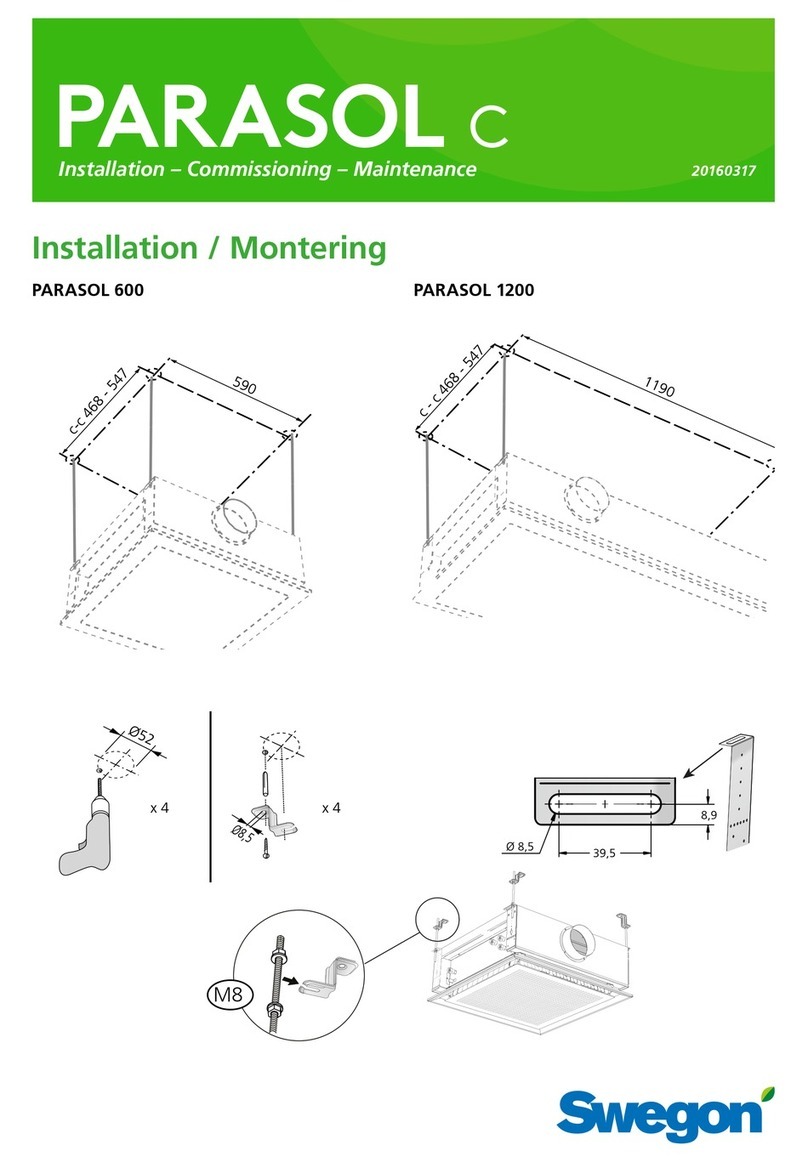

4.4 Mounting Sets

The fans are usually connected to an I-beam

Accordingly, this element as standard is included in every packaging unit.

Optional mounting set for concrete structure

Optional mounting set for side mount on concrete

Optional mounting set for bent structure

Standard Mounting Set

(for I-Beam)

Article no

19580220

Weight: 14 kg

Mounting Set

for

concrete structure

Article no.

19580222

Weight: 26 kg

Mounting set for

side mount

on concrete

Article no.

19580223

Weight: 16 kg

Mounting Set

for bent stucture

Article no.

19580224

Weight: 26 kg

www.monsterfans.com info@monsterfans.com 11

4.5 Extension Elements

The MonsterFans fans are delivered ex-works with a hanging element of standard 1m.

Optionally, we offer another 1 m and 2 m extension element and a connection piece to

connect two extension elements.

The max. length of these extension elements must not exceed 3 m consisting of max. 2

elements. Likewise, only one connection set may be used to connect two extension

elements. Otherwise the stability of the fan can be influenced.

Extension tube Optional Extension tube 1,5 m length

1 m standard length Article no 19580231

Article no: 19580230 Weight: 12 kg

Weight: 8 kg

Optional Extension tube 2 m length

Article no 19580232

Weight: 16 kg

Connecting piece for extension tubes incl. bolts & screws:

Article no. 19580239

Weight: 3 kg

4.6 Wire rope clamps & Thimbles

EN 13411-5:2009-02 stipulates the use of at least 3 wire rope clamps and thimbles for end

connections for steel wire ropes of nominal size 5 mm.

The first wire rope clamp should be attached directly to the thimble. The clamp should

always be attached to the loaded part of the rope.

The distance "e" between the wire rope clamps should be at least 1.5 "t" and not more than 3

"t", where "t" is the width of the clamp jaw.

When making the connection and before commissioning, the collar nuts should be tightened

to a torque of 2 Nm. The recommended tightening torque applies to wire rope clamps where

the contact surfaces and threads of the nuts have been lubricated.

After the first application of the load the tightening torque should be checked again and

corrected if necessary.

www.monsterfans.com info@monsterfans.com 12

4.7 Installation of MonsterFans

Start by installing the mounting element on the ceiling.

Attachment of the

suspension &

extension element

Pull your electrical cable through the extension tube.

Then attach the safety steel rope (parts list no 9) and secure it with the steel wire lock (no 10).

Observe the notes on wire rope clamp connections.

Mount the motor housing with the motor on the extension element.

Use the M16 x 120 mm screws for this. Pay attention to an exactly horizontal alignment.

www.monsterfans.com info@monsterfans.com 13

Note: The safety steel ropes must be aligned symmetrically for the same load, then tightened

evenly, use the turnbuckles and a threadlocker glue at the end.

Connect the motor supply cable to the motor terminal box. Observe the instructions in

chapter 4.8 Electrical connections.

Now assemble the fan blades. Use the M10 x 100 mm screws. Pay attention to an exact

alignment of the rotor blades and use threadlocker glue. When assembling, make sure to

connect all retaining brackets (parts list no.6) to each other. Then install the bottom plate

(parts list no 8) with the screws M5 x 12 mm (no 7).

www.monsterfans.com info@monsterfans.com 14

Now wire the cable to the Controller box.

Use your own electrical cable for this.

Now install the Controller Box. We recommend installing it at a height of approx. 1.6 m.

The 3-pole switch disconnector (parts list no. 20) must be mounted and integrated in the

direct vicinity of the Controller Box. Operation is only permitted with an emergency stop

mechanism! The switch-disconnector may only be operated in emergency situations. An

interruption of the power supply during operation can damage the frequency inverter as

well as the motor!

Use a adequately dimensioned and EMC-compliant power cable for the motor connection,

such as: LAPP ÖLFLEX® CLASSIC 110 CY 4 G 2.5 [or equivalent].

4.8 Electric Connections

Apply the supply voltage, 3 ph + PE, to the "control supply line" terminals. The motor supply

cable is connected directly to the frequency Inverter, the shielding next to the strain relief is

connected to the PE. The start command of the frequency inverter can be brought out and

interrupted via the remote release contact.

Figure: Controller Connection Figure: Inverter connection

www.monsterfans.com info@monsterfans.com 15

To connect the motor please remove the MonsterFans cover from the motor housing above

the motor terminal box and unscrew the cover from the motor terminal box. Lead the motor

connection cable through the EMC gland and pay attention to the position of the shielding

braid.

Figure: LAPP Skintop MS-SC EMC Cable Gland Schematic Shielding Connection

For the motor wiring, please remove the MonsterFans cover from the motor housing above

the motor connection box. Then wire the motor in star cabling according to the connection

diagram above. The fan is operated exclusively with 3 phases, 400 volts AC.

Nord Motor Wiring Clamps with a Star Connection Stud Wiring Fan Motor

4.9 Oil Check and Oil Safety Pin

Please also check the oil level before starting up. There is a safety pin on the

bleed screw. The safety pin must be removed before the initial start-up. The

engine is operated with synthetic oil (lubricant: Synth ISO VG 680, 3.1 litres).

The safety pin is provided with a cable tie ex works to make the safety pin visible and to

make it easier to remove the safety pins.

www.monsterfans.com info@monsterfans.com 16

After proper cabling and checking, you can turn on the power. The area around the fan

must be free of obstacles. Start with a test run of 10 minutes.

If the operation of the fan works properly, instruct the operator and please use the handover

protocol for a formal handover.

5Frequency Inverter

A variable frequency drive is integrated in the MonsterFans Controller Box. You will find

detailed technical instructions from the manufacturer attached. The frequency Inverter is

pre-programmed at the factory and ready for operation.

You will also find the following Wiring Diagram (3~400V, 50 Hz) printed inside the

Controller Box.

www.monsterfans.com info@monsterfans.com 17

6Commissioning

6.1 Test Run

Ideally, test the fan for 10 minutes to see if there is any unusual noise, vibration from the

device or from the safety steel ropes.

Also make sure that the fan runs safely with a sufficient safety distance to all possible

obstacles.

6.2 Warnings

•A change in shape or the bending of rotor blades is strictly prohibited.

• Please do not carry out any work or repairs while the device is switched on in order to

avoid an electric shock.

• Please do not change the original technical structure of the fan.

• Please do not open the switch box / controller box during operation to avoid an

electric shock.

• Do not operate devices with malfunctions as this can lead to serious injuries.

• Structural or parameter changes to the electrical control box are strictly prohibited, as

this can lead to equipment damage, injuries or death due to improper use.

• After disconnecting the power supply, there may still be a residual voltage in the

controller box. Wait 2 minutes until the contacts are de-energised. Switching off the

display is not an indication that there is no voltage.

• The installation and laying of the electrical cabling must be carried out by a qualified

specialist.

• Please use the device components enclosed and specified by MonsterFans.

•Do not interrupt the power supply while the fan is running. Otherwise the fan will be

damaged. The power supply may only be switched off, after the rotating blades have

stopped completely.

6.3 Troubleshooting

Common causes of incorrect operation:

• The supply voltage is incorrectly selected or switched off.

• If the fan does not work, please check first if the speed controller is at MIN and check

also the Run/Stopp button.

• Unauthorised personnel must not open the Controller Box. Our local service partner will

send you a trained specialist for repairs or adjustments.

• If you notice, that the fan or Controller Box is damaged or has unusual noises, stop using

it with immediate effect. Switch off the power supply and contact your service partner.

• A damage of the device caused by improper use is not covered by the warranty.

Commissioning;

1. Make sure that the fan can run free of

obstacles.

2. Check the direction of rotation of the blades,

regular operation is counter-clockwise.

3. Make sure that the input voltage is correct and

meets the requirements.

4. Set the speed controller to the minimum

position.

5. Switch on the fan and turn the switch from STOP

to RUN.

6. After the fan has started, set the speed control

knob to the desired speed.

Caution:

1. It is prohibited to interrupt the

power supply during fan

operation.

2. The fan is not designed for reverse

operation.

3. The direction of rotation can only

be changed by phase rotation on

the frequency converter.

www.monsterfans.com info@monsterfans.com 19

7Warranty & Maintenance

Our quality assurance applies to the entire fan.

The warranty period begins on the date of acceptance by the customer after professional

installation and commissioning. This ends with the statutory warranty period. The following

causes are not covered by the warranty:

1. Improper use, incorrect installation, incorrect commissioning and unauthorized

maintenance.

2. Operator assembles / disassembles the product independently.

3. Force majeure (lightning, earthquake, terror, flood etc.).

To ensure a long service life, we recommend regular maintenance and professional

inspection.

Intervals Maintenance Work

Yearly 1. Check the correct rotation of the fan.

Disconnect the fan from power supply for further maintenance work!

Secure the maintenance area on the floor as well.

2. Check all safety bracing devices.

3. Check all fastening screws and connecting elements

4. Check the electrical connections and cabling.

5. Check the gearbox for oil leakage.

6. Check all suspension and connection elements.

7. Check the wing connection bolts under the base plate

8. Check the wings and engine components for damage.

9. Check all fan components for signs of corrosion,

discoloration, pitting and metal spalling.

10. Check the guy wires for damage or abrasion.

11. Removal of dust and dirt particles from wings and motor.

Every five years (or every 20,000 operating hours)

▪Check the oil level, carry out an oil change if necessary.

If a fan runs with strong unusual noises or vibrations, this indicates that the mechanical parts

are damaged. Switch off the fan immediately and carry out a comprehensive inspection

and maintenance.

In the event of faults within the warranty period, please do not try to correct them yourself.

Please contact your manufacturer.

www.monsterfans.com info@monsterfans.com 20

8Packaging Units

A MonsterFan is delivered in two wooden boxes.

Picture: Wooden Box Fan Blades Picture: Wooden Box Motor

Type

Diameter

Dimensions

Weight

Total

MF-C24

7.3 m (24 ft.)

Box Motor:

950 mm*830 mm*520 mm

Box fan blades:

3700 mm*420 mm*450 mm

180 kg

127 kg

307 kg

MF-C20

(on request)

6.1 m (20 ft.)

Box Motor:

950 mm*830 mm*520 mm

Box fan blades:

3100 mm*420 mm*450 mm

180 kg

117 kg

297 kg

MF-C16

4.9 m (16 ft.)

Box Motor:

950 mm*830 mm*520 mm

Box fan blades:

2500 mm*420 mm*450 mm

180 kg

107 kg

287 kg

MF-C12

3.6 m (12 ft.)

Box Motor:

950 mm*830 mm*520 mm

Box fan blades:

2100 mm*420 mm*450 mm

180 kg

97 kg

277 kg

This manual suits for next models

4

Table of contents

Other Schwank Fan manuals

Popular Fan manuals by other brands

Klimawent

Klimawent SMART-EC-1300 Use and maintenance manual

STIEBEL ELTRON

STIEBEL ELTRON LTM dezent 300 NHR Installation

Lasko

Lasko 2711 user manual

Westinghouse

Westinghouse Sparta series instruction manual

Greenheck

Greenheck RSF Series Installation, operating and maintenance manual

Airflow

Airflow Uno hab Installation kit