CRAFT-TIG-Series | Version 1.06 3

Contents

1 Introduction.............................................................................................. 4

1.1 Copyright .............................................................................................4

1.2 Customer service.................................................................................4

1.3 Limitation of liability..............................................................................5

2 Safety........................................................................................................ 5

2.1 Symbol explanation .............................................................................5

2.2 Qualification of the staff .......................................................................6

2.3 Personal protective equipment............................................................6

2.4 General safety instructions ..................................................................7

2.5 Safety markings on the welding machine............................................7

3 Intended Use............................................................................................ 8

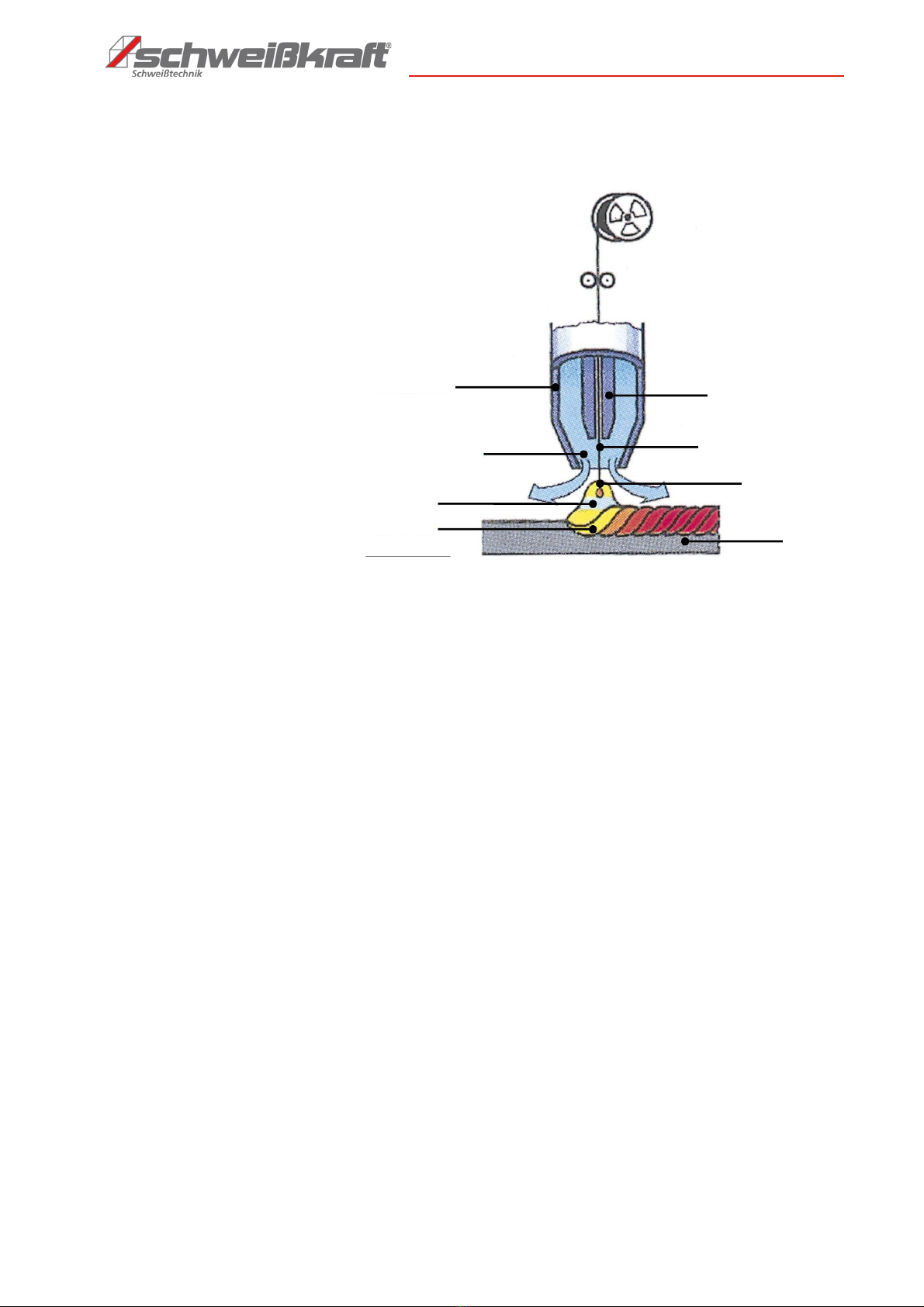

4 Principle of operation.............................................................................. 9

4.1 Principle of tungsten inert gas welding ...............................................9

4.2 Principle of manual arc welding (MMA)...............................................10

5 Technical Data.....................................................................10

5.1 Table....................................................................................................10

5.2 Type plate............................................................................................12

6 Transport, packaging, storage...........................................12

6.1 Transport..............................................................................................12

6.2 Packaging............................................................................................12

6.3 Storage ................................................................................................12

6.4 Installation conditions ..........................................................................12

7 Scope of delivery.................................................................13

8 TIG-Inverter characteristics...............................................13

8.1 Function principle ................................................................................14

8.2 Volt-Ampere Characteristic..................................................................15

8.3 Duty cycle and thermal protection.......................................................16

8.4 Assembly of equipment (TIG/WIG)......................................................16

8.5 Polarity connection (MMA)...................................................................18

9

Description of the operating and connection elements

.......19

10 Welding..............................................................................27

10.1 Welding methods...............................................................................31

10.2 Welding current .................................................................................31

10.3 2-T operation......................................................................................31

10.4 4-T operation......................................................................................31

10.5 Pulse function ....................................................................................32

10.6 Starting with welding..........................................................................32

10.7 TIG welding........................................................................................33

10.8 Welding with rod electrode (MMA)....................................................34

10.9 TIG welding........................................................................................35

10.10 Argon ARC welding application ......................................................35

11 MMA welding.....................................................................38

12 Electrical connection........................................................39

13 Welding instructions.........................................................39

13.1 Notes to the welding technology .......................................................40

14 Care and maintenance......................................................42

15 Troubleshooting................................................................44

16 Disposal, Recycling of old equipment.............................50

16.1 Decommission ...................................................................................50

16.2 Disposal of electrical equipment .......................................................50

16.3 Disposal via municipal collection points............................................51

17 Spare parts........................................................................51

17.1 Spare parts order...............................................................................51

17.2 Spare parts drawings ........................................................................52

18 Wiring diagram..................................................................54

19 Electrical circuit diagrams................................................56

19.1 Electrical circuit diagram CRAFT-TIG 201 DC P PULSE ...................56

19.2 Electrical circuit diagram CRAFT-TIG 253 DC PULSE ......................57

20 EC Declaration of Conformity..........................................58

21 Notes..................................................................................59