Service Manual

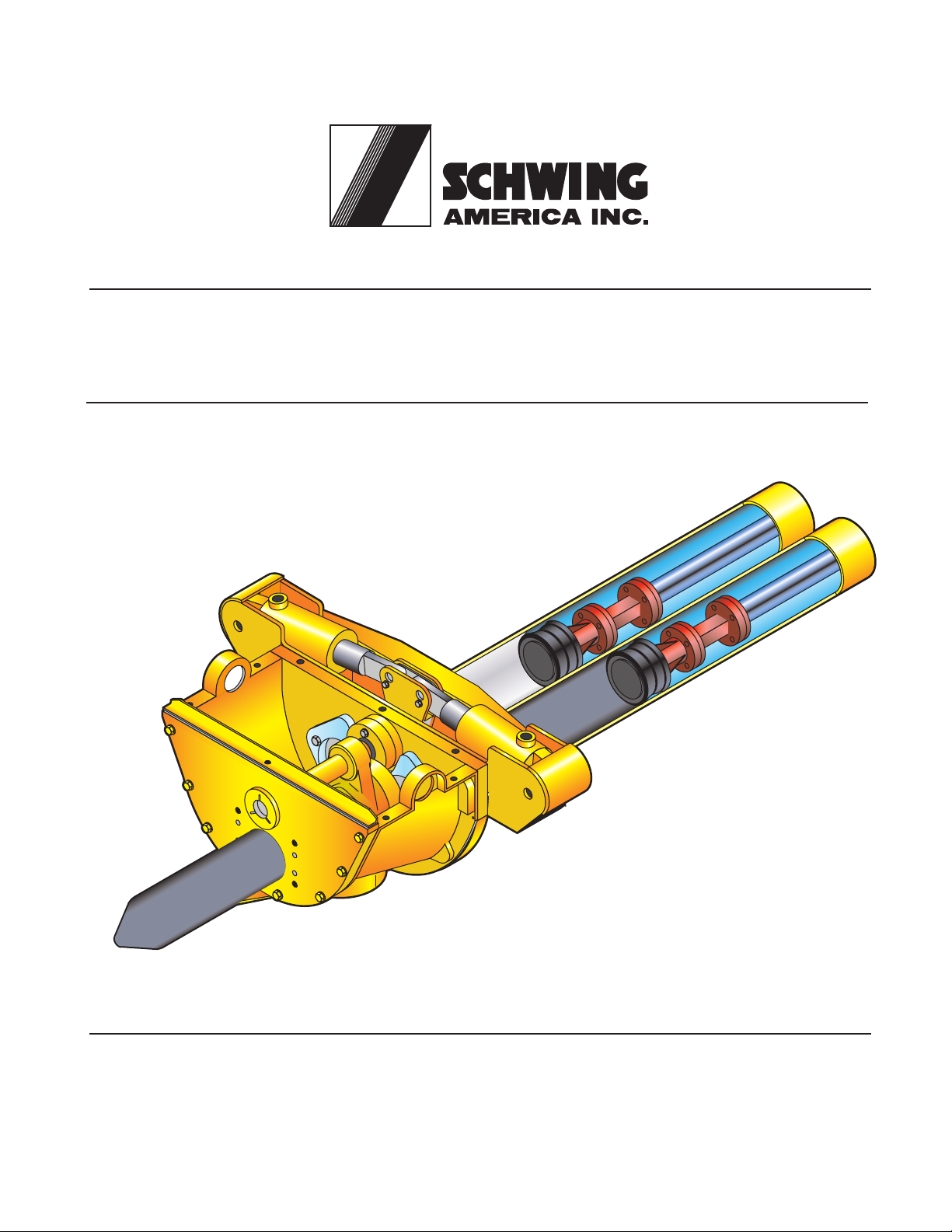

Small Rock Valve

1

Small Rock Valve

Safety Instruction

When performing maintenance on Schwing Equipment, the safety regulations must be followed. The observation

of these regulations is the responsibility of the maintenance personnel. The following are some supplementary rec-

ommendations.

1. WARNING! Read and understand the operation manual of the machine before attempting any repairs. If in

doubt, call the manufacturer. Incorrectly done repairs endanger operational safety of the machine.

2. WARNING! Burning hazard! Never work on a hydraulic system with hot oil.

3. WARNING! Falling hazard! If you cannot work at ground level, you must use a suitable work platform.

4. WARNING! If maintenance work requires that you use a crane, hoist, fork truck, etc., you must read and

understand the safety regulations for that equipment.

5. WARNING! If working the machine requires that it be operated, and you are not qualified as an operator, you

must get someone who is qualified to assist you.

6. WARNING! If you will be working in a hidden area inside the machine, protect yourself by taking the key

from the ignition and putting a “DO NOT OPERATE” sign on the controls. In the case of electrically driven

units, disconnect the main circuit breaker and lock it in the disconnected position.

7. WARNING! Never activate the system hydraulics without checking if another workman is in a hidden posi-

tion. Always yell “CLEAR”, and allow time for response, before starting the prime mover.

8. WARNING! Never use gasoline or diesel fuel as a cleaning solvent. This is critical to remember when clean-

ing hydraulic oil reservoirs, because gas and diesel fuels are highly explosive, and gasoline or diesel fuel traces

left in the oil may ignite when compressed.

9. WARNING! Always use the correct tools for the job. Tools should be kept clean, and in good condition.

10. If you see a co-worker engaging in an unsafe practice, explain the dangers. Safety is always in the hands of

those on the job.

11. WARNING! Never work on a pressurized hydraulic system. Stop the prime mover and relieve the accumulator

circuit (if so equipped) before you open the hydraulic system.

WARNING

READ FIRST!