SAFETY

READ ALL INSTRUCTIONS BEFORE USE. FAILURE TO

FOLLOW THESE PRECAUTIONS COULD RESULT IN INJURY TO

YOURSELF AND OTHERS

1. Use the Metabolic shaker on an individual 15A mains outlet

only. DO NOT OVERLOAD THE CIRCUIT.

2. Ensure that the equipment and the power supply cord does not

come into contact with hot surfaces.

3. This unit is only to be used by properly trained laboratory staff.

4. If the supply cord is damaged, it must be replaced with a new

cord assembly available from the suppliers agent.

5. Use only earthed outlets matching the serial plate voltage.

6. Have equipment installed by a qualied personnel in accordance

with local codes and ordinances.

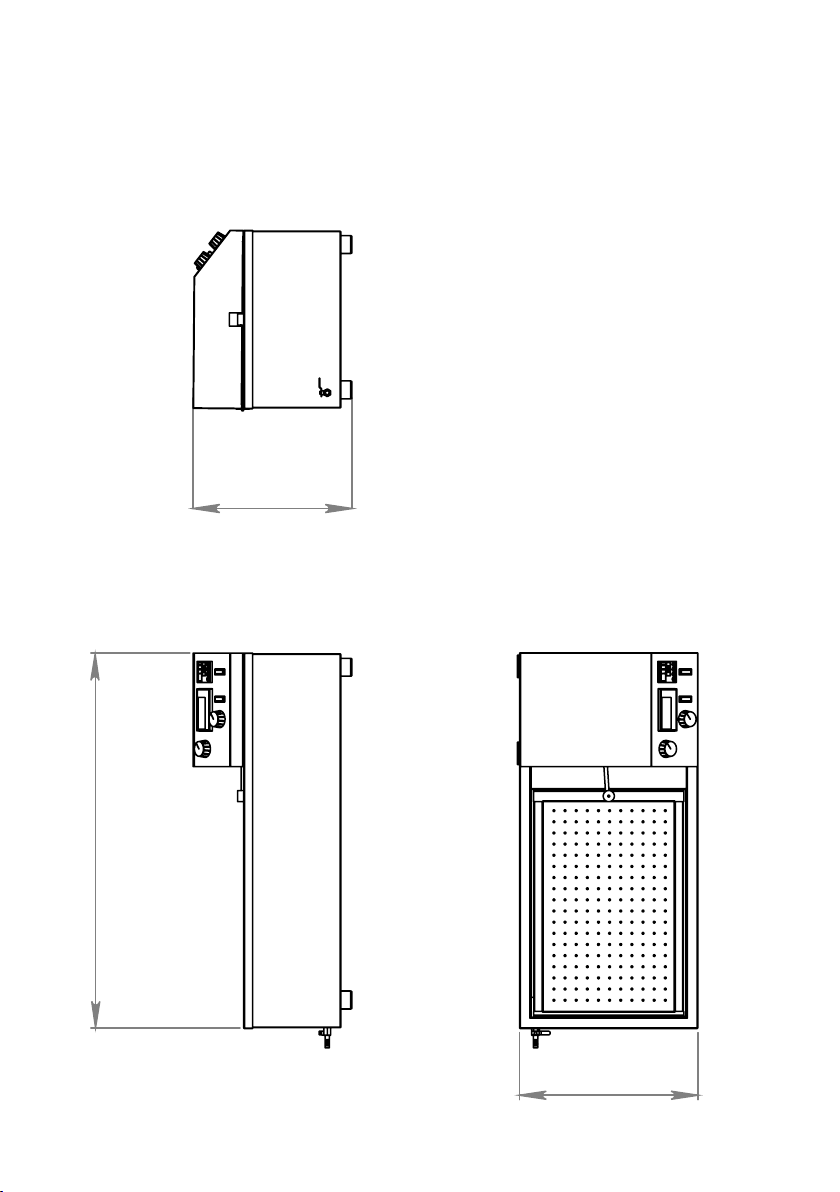

7. Use equipment in a at level position.

8. Do not operate if equipment has been damaged or is malfunc-

tioning in any way.

9. These units are designed to run only on alternating current

(A.C.) DO NOT CONNECT TO DIRECT CURRENT (D.C)

WARNING

Electric Shock Hazard.

Keep water and other liquids from entering the inside

of the equipment. Liquid inside the equipment could

cause an electrical shock

Do not spray water or cleaning products. Liquid could contact the

electrical components and cause a short circuit or an electrical shock.

Do not use equipment if power cord is damaged or has been modied

SAFETY RECOMMENDATIONS

1. When loading and unloading the shaker platforms, turn the

speed control to a slow setting and switch off the mains

switch.

2. Be aware of the range of movement of the platform and keep

objects clear of the shaker before switching on.

3. Never let the tank run dry as this will result in over heating of the

elements.