Scion 456-GC User manual

Reference Manual

CO/CO2 Analyzer

SCION Instruments HQ SCION Instruments NL BV

Suite 34, Livingston Business Centre, 4462, Goes,

Kirkton Road South, Livingston, Stanleyweg 4.

EH54 7FA, Scotland, UK. The Netherlands

Tel: +44 1506 300 200 Tel: +31 113 348 926

sales-[email protected] sales-[email protected]

www.scioninstruments.com www.scioninstruments.com

Revised February 2019

© 2015 Scion Instruments

SCION Instruments

Scion Instruments CO/CO2Analyzer Page 2

SECTION CONTENTS

INTRODUCTION...........................................................................................................3

INSTRUMENT SPECIFICATIONS ............................................................................4

INSTALLATION OF COLUMNS, FLOW AND PRESSURE SETTING ..............5

TUNING OF THE CO/CO2 CHANNEL.....................................................................6

OPERATION ..................................................................................................................9

TROUBLE SHOOTING.............................................................................................. 11

STEP BY STEP............................................................................................................ 12

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 3

INTRODUCTION

The CO/CO2Analyzer Channel is an analytical tool principally developed for

the simultaneous determination of carbon monoxide, methane and carbon

dioxide in various gaseous hydrocarbon matrices or pure-gas samples.

The sample is injected by means of a gas-sampling valve onto a series of

Hayesep-R columns. The first fraction, containing the components of

interest is sent to a methanizer-FID combination; the rest of the sample is

backflushed.

The CO/CO2Analyzer Channel is set for the determination of the mentioned

components down to sub ppm levels.

The instrument is tuned during Final Test to its proper settings. Do

not change any flow or pressure settings unless it is requested.

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 4

INSTRUMENT SPECIFICATIONS

The instrument specifications are published in the corresponding Data

Sheet

Every instrument is fully tested; the results of the tests, as well as the

methods used during these tests, are presented as part of this manual (refer

to section 1).

START UP

At initial START-UP as well as after a longer idle period,

follow the instructions below:

•

Connect all the gases to the instrument.

•

Switch the power on.

•

Load the appropriate method.

•

Check the flow settings.

•

Condition the system as described in this manual.

•

Do not make any changes to the methods

•

The system is ready for injections.

For a new system there is no need to do any flow measurement or

flow tuning before power-up. The instrument is tuned and tested in

our factory in Goes.

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 5

INSTALLATION OF COLUMNS, FLOW AND PRESSURE SETTING

Tuning of the analyzer is only necessary in case new columns are

installed or after flow of pressure settings have been changed. New

columns have to be preconditioned, prior to installation!

Tuning of the analyzer is only necessary in case new columns are installed or

after flow or pressure settings are changed.

Make sure, the instrument is connected to the minimum gas supply

pressures as indicated in the pre installation requirements (in section 2 of

this manual).

For more detailed information concerning the configuration of the

instrument, please, refer to the drawing section (section 6 of this manual).

The drawing also outlines the way the analyzer channel has been

incorporated into the gas chromatograph.

Regularly check and replace filters in order to maintain the quality of

the gas supply as described in the pre installation requirements.

Replacement columns:

SC15892: SS COLUMN HAYESEP R 2.6M. (pre-column)

SC15886: SS COLUMN HAYESEP R 1M. (analytical column)

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 6

TUNING OF THE CO/CO2 CHANNEL

Connect the columns according the flow schematics given in Section 6

and adjust the flows (if necessary) at an oven temperature of 50°C.

Take very good care not to create any dead volume.

•Set the injection/backflush valve V1 to the inject (+) position.

•Disconnect both columns from the pressure point Tee and connect both

columns to each other using a 1/8” union.

•Set the front EFC-24 pressure to give a flow of 20 ml/min measured at the

FID outlet.

•Remove the 1/8 “union between the two columns and reconnect the

columns at the pressure point union Tee.

•Set the middle EFC-24 pressure to give a flow of 25 ml/min measured at the

FID outlet.

•Program for each EFC-24 module the total flow as mentioned in the

'OPERATION' paragraph.

•Adjust the Hydrogen Manual Flow Controller to give a flow of 20 ml/min

measured at the FID outlet (Note: total carrier plus Methanizer hydrogen is

45 ml/min)

•Set the injection/backflush valve to the load(-) position. Set the needle valve

NV-1 controlling the backflush flow to 20 ml/min, to be measured at vent 1.

Check all connections for leakages.

It is advised to use an electronic leak detector, since 'Snoop' or

equivalent soap solutions contaminate the analytical flowpath of

your instrument.

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 7

The system is now ready for conditioning

Run the method continuously overnight to condition all columns.

Inject a reference sample, containing all relevant components, preferably in

helium or nitrogen. The result should look like Figure 1.

Set the backflush of the Hayesep columns to allow full recovery of the CO2.

Depending on the sample matrix, pure-gases or ethylene or propylene and

depending on the sample loop installed, the optimum backflush time may

be different. The optimum backflush time must be determined for the

individual matrices. See Figure 2 for trace determination of CO and CO2in

propylene.

Figure 1: CO/CO2analyzer example chromatogram (sample loop: 0.5 ml)

The individual concentrations are around 50 ppm in nitrogen.

Minutes

0

1

2

3

4

5

6

7

8

9

10

Vol

ts

0.005

0.010

0.015

0.020

0.025

0.030

Vol

ts

0.005

0.010

0.015

0.020

0.025

0.030

Detector 1

CO

CH4

CO2

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 8

All factory tests are performed using helium as the carrier gas. However,

nitrogen or hydrogen may be used as the carrier gas. The choice depends

on the final application. If another gas as helium is the carrier gas, the

various detector flows as well as the method need to be adapted to the new

situation.

Figure 2: Example chromatogram of propylene matrix (sample loop: 5 ml)

The concentration of Carbonmonoxide is 100 ppb.

Minutes

1

2

3

4

5

6

7

8

9

Vol

ts

0.002

0.003

0.004

0.005

0.006

0.007

0.008

0.009

Vol

ts

0.002

0.003

0.004

0.005

0.006

0.007

0.008

0.009

Detector 1

CO

CH4

CO2

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 9

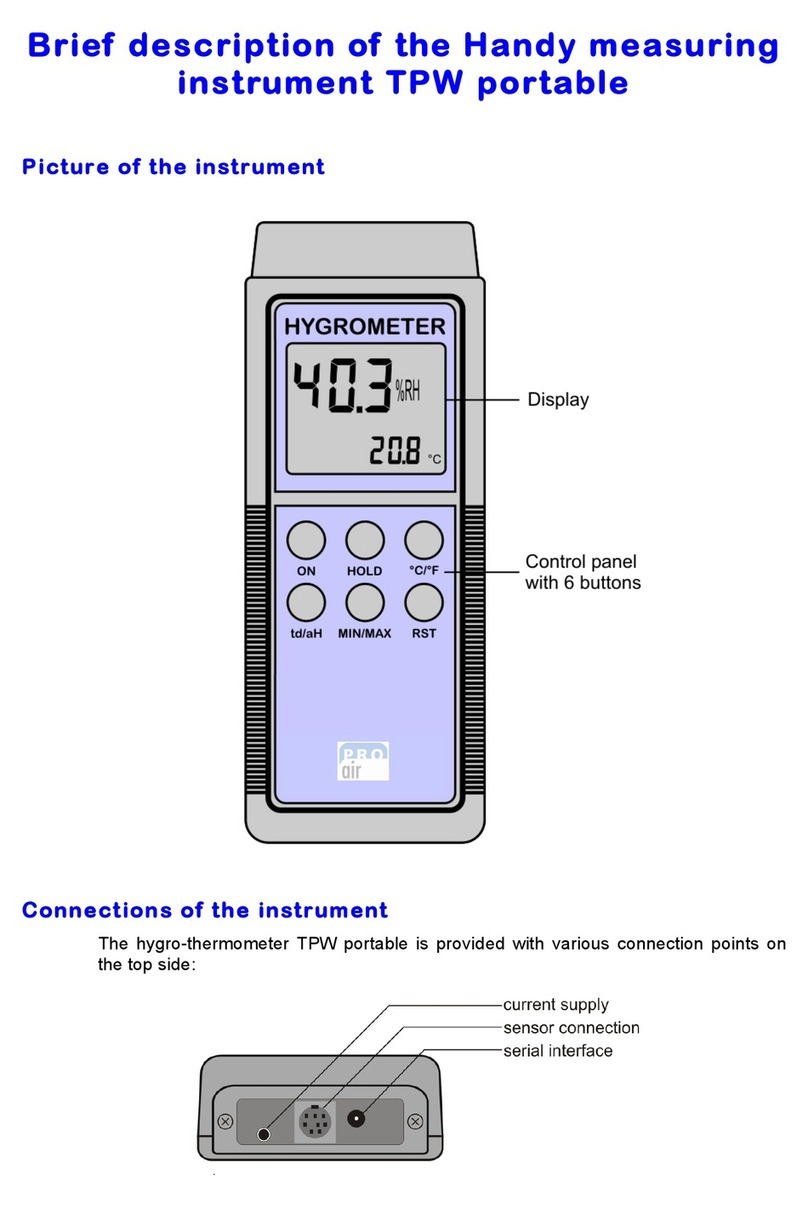

OPERATION

An operational method is preloaded in the instrument.

Listed below is an example method; settings determining the application

may be different.

Sample delivery:

V1 (IBV)

V2 (S)

Initial

-

-

initial state

0.10

-

+

sample flush

0.80

-

-

sample flush (stop)

1.00

+

-

injection

4.50

-

-

backflush

Flow/Pressure

Front EFC-24 (He):

Pressure (PSI)

Hold (min)

Initial:

27.5

15

Total Flow: 50 ml/min

Middle EFC-24 (He):

Pressure (PSI) Hold (min)

Initial:

14.5

15

Total Flow: 50 ml/min

Column Oven:

Temp(ºC)

Rate(ºC/min)

Hold(min)

Total(min)

Initial

50

0

15.00

15.00

Valve Oven:

Temp: 100 (ºC)

Methanizer Oven:

Temp: 400 (ºC)

Flow (H2) 20 ml/min

Detector (Middle FID):

Temp: 200 (ºC)

Range: 12

Time Constant: slow

Front DEFC 11:

Air flow: 300 ml/min

H2: 10 ml/min

Make up: 15 ml/min N2

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 10

This method is only valid in case the instrument is equipped with one

CO/CO2 Analyzer channel only. Refer to section 1 for the actual method(s),

whenever the instrument has combined channels.

Never interrupt an analytical run. The complete cycle has to finish.

The sample has to be connected to the 'sample in' at the right-hand side of

the instrument. The 'sample out' is preferably connected to a fume hood or

other exhaust.

At the beginning of the run, the sample loop is flushed for about 1 minute

(this is part of the method). Just before injection, the sample flow is stopped

to allow equilibration of the sample to atmospheric pressure.

In case there is a large difference in concentration between two consecutive

runs it is advised to allow for a pre-flush of the sample loops before starting

the automated run. This is done by manually activating the sample solenoid.

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 11

TROUBLE SHOOTING

For problems related to the basic hardware and electronics of the gas

chromatograph, as well as injectors and detectors, refer to the 456-GC user

manual.

In case of any analytical problem, it is always advised to record an analysis

using a reference sample. The result, including full details can be submitted

to your local Scion Instruments service department to judge performance.

The presence of oxygen in the sample will influence the (accurate)

determination of carbon monoxide. This is due to the oxidation of deposited

carbon on the methanizer, and almost coëlution of oxygen and carbon

monoxide.

If a hydrocarbon gas, ethylene or propylene is the sample matrix, the

backflush time must be set to have maximum recovery for carbon dioxide in

combination with complete backflush of the matrix components. High

amounts of hydrocarbons will create excess deposition of carbon on the

methanizer column, reducing the methanizer lifetime.

Trace impurities of oxygen and carbon dioxide in the carrier gases, may

easily influence the determination at low levels. Increased noise levels will

have a negative influence on the limits of detection. Carefully follow the pre-

installation requirements concerning carrier gas purity and filter

requirements.

The methanizer needs to be replaced in case of:

•severe peak tailing for carbon monoxide and carbon dioxide

•variations in the conversion efficiency of the methanizer

•missing carbon monoxide and carbon dioxide.

CONSUMABLES

Partnumber Description

03-923720-31 Nickel catalyst column

03-911600-02 30 % Nickel Nitrate on Chrom PAW 100-120 mesh

SC15892 SS column Hayesep R2.6M

SC15886 SS column Hayesep R 1M

BRF0102 Super Clean™ Gas Filter OXYGEN

BRF0101 Super Clean™ Gas Filter MOISTURE

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 12

STEP BY STEP

Step by step customer drawings CO/CO2Analyzer

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 13

Fill position

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 14

Inject position

Scion Instruments

Scion Instruments CO/CO2Analyzer Page 15

Backflush position

Table of contents