2

Before installation, please ensure that the following requirements are met:

1. Professional configuration of the device in line with its use

2. Installation of the device in line with the assembly and operational manual

3. Operation of the device in the scope of the approved conditions of use

4. Regular visual checks in line with the manufacturer’s instructions

Intended use

General use

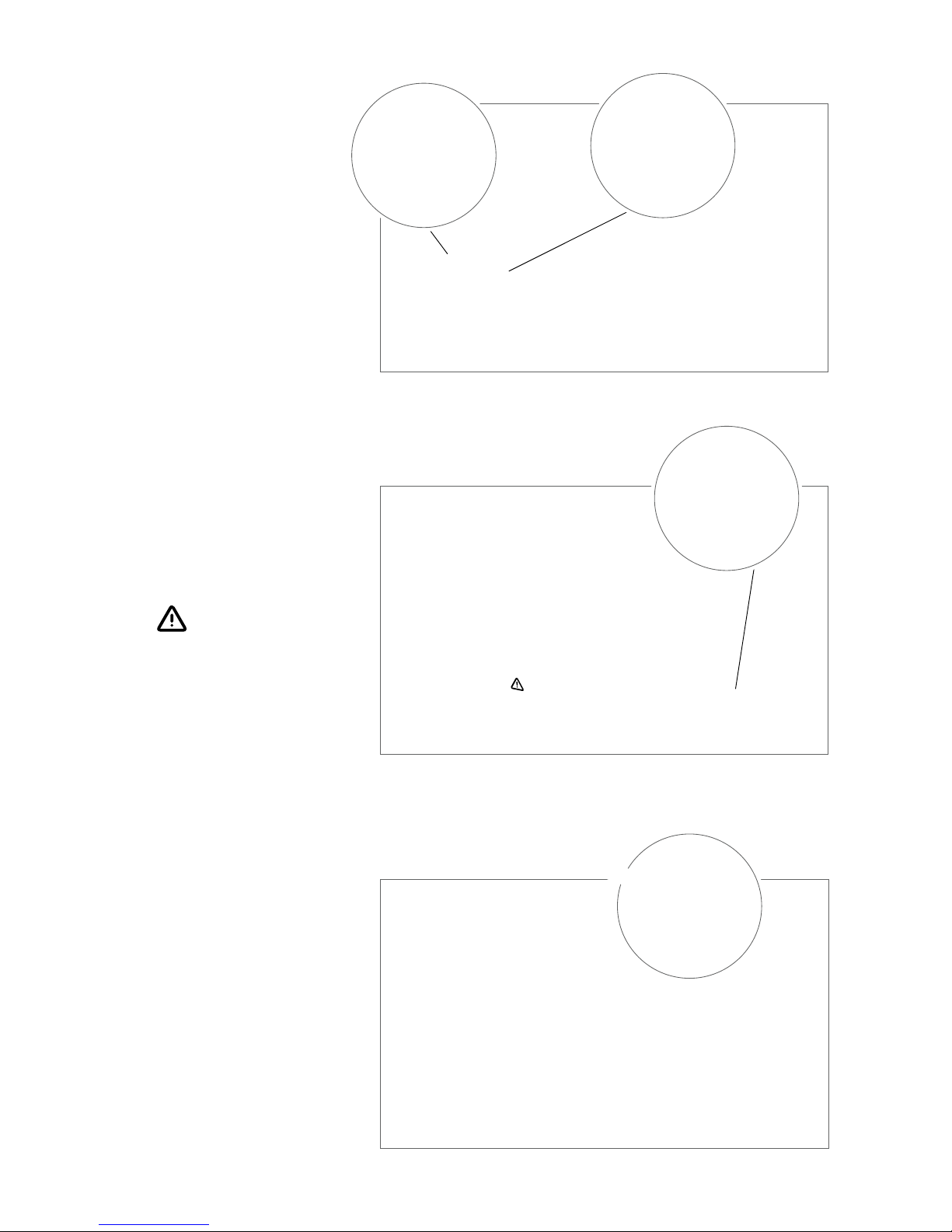

AirScrape is a Contact Free Conveyor Belt Skirting system which hovers freely above

the conveyor belt, eliminating skirt friction and belt damage. Its unique array of

inward facing hardened steel diagonal blades, deflects larger particles inwards

while using the airflow of the conveyor belt and conveyed material to create an

inward suction, sucking or drawing any dust and fine particles back into the product

flow.

Component modification

Modifications of components and deviating configurations, installations, operations

and maintenance are subject to written approval of ScrapeTec. Failure to observe

these instructions could lead to increased risk of injury and damage.

Warning instructions

• During operation, unpredictable belt movements may occur, with a danger of

crushing. Owners must take appropriate safety measures (safety guards, warning

notice).

Safety measures during installation and maintenance work

• Installation and maintenance work on AirScrape blades must only be performed

when the conveyor belt is stationary and locked out. Cordon off the work area.

The work must be approved by the responsible works manager.

• Always use appropriate PPE.

• Always seek the owner’s permission if you need to perform welding or cutting (hot

work permits).

• If there is a risk of working at heights (working at heights permit) use of scaffolding,

railings, safety nets and harnesses and all other relevant safety equipment is

strongly advised.

• Before commissioning the Contact Free Conveyor Belt Skirting AirScrape, always

ensure that the work site is completely clear and parts, such as scaffolding, lifting

gear and tools are removed from the area. All guards have to be refitted to the

previous locations.

• Check that all screwed connections are securely tightened following any

commissioning and maintenance work.

• Use original parts only.