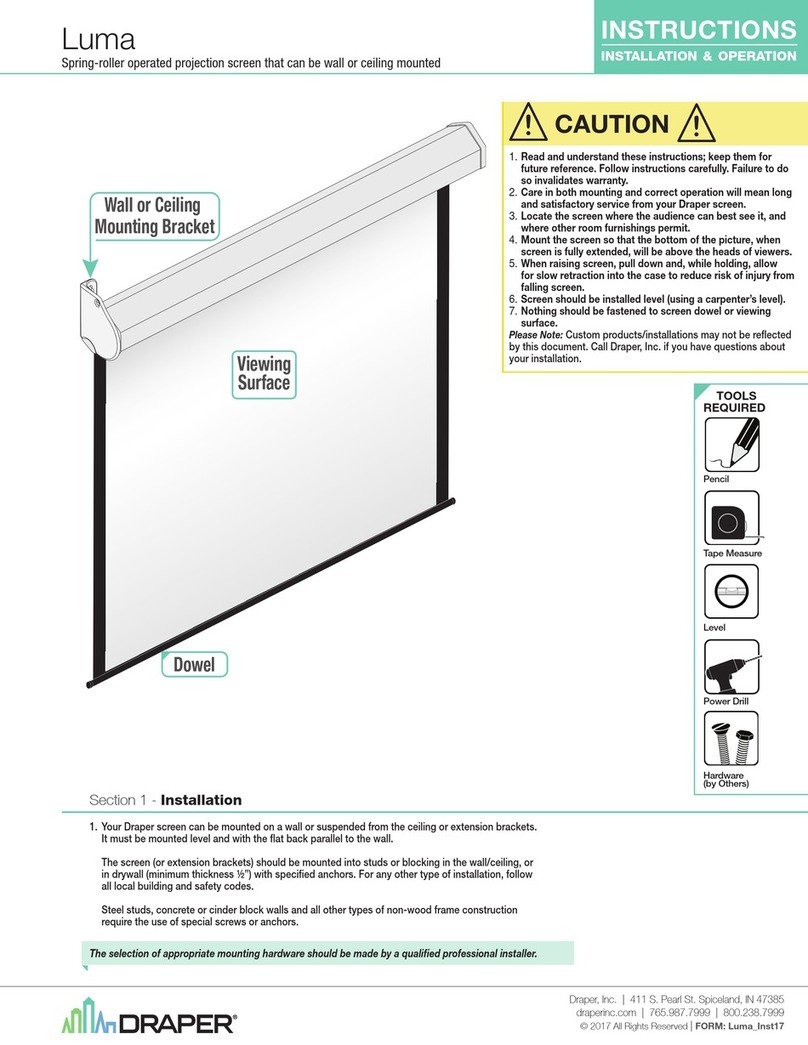

11.Connect the 2 motors to the corresponding XLR 3 (or 4) pins type

connectors on the connection box behind the central part of the subframe

12.Connect the connection box to the CB2/5 or CB2/10 control unit with the

provided 6 pin connector, and connect the CB2/5 (10) to mains

13.Operate the motors to check the stops adjustments using the “open” and

“close” green buttons on the top right of the remote –for RF / IR or

“open” and “close” command from RS232 devices you use

14.Check carefully in the “open” position that when the leading edge of the

mask is at rest, the motor is off (put your hand on the roller and check

that it’s not vibrating or heating).

15.If the motor is still on, it means that the stop adjustment has been lost

during transport. In that case, you will have to readjust mechanically the

stop to have the mask leading edge exactly aligned with the edge of the

main frame profile. You can adjust the stops with a Hex key (provided) at

the motor head.

16.Check carefully in the “close” position that the leading edge defines

exactly an aspect ratio of 1.33

17.Repeat this checks for both motors