5

want to make sure it's free to drop before you let the screen surface go down. Getting that layer

backwards-wound in the case is a disaster.

9) Connect the Mains supply ground and neutral to the green& yellow wire and to the blue wire of the

motor, respectively. Then connect the live of the Mains to the central contact of the rocker switch, the

brow motor wire to the UP positionof the rocker switchand the black motor wire to the down position.

10) Don't worry about the tape on the weight bar. You can get that off after you drop the screen. After

youare sure the black backing is free to drop and all other blue bits are off the screen, plug it in and hit

the down button.

11) Check that the lower limit is ok, then remove any remaining blue bits.

12) Check the vertical turnbuckles at the weight bar. Make sure they’re not bound up, either with the

cables twisted at the top of the eyelet, or the threads on the bar. If they are, the bar will be artificially

lifted, resulting in waves. Straighten any twisted cable and wiggle the bar to get it off the threads.

13) Check how the vertical cable and turnbuckles retract up into the screen case. You want them to

easily retract up into the case, without getting caught or hung up on either the front side of the case

near the foam strip, or the back side. If you hear any “clunk” sound, or see the motor bog downbefore

the screen is all the way up, check that these turnbuckles aren’t getting hung up. The fix is to just grab

the metal portion of the weight bar and rotate a few degrees to better align the turnbuckles into the slot.

14) If there is provided a remote control system, disconnect completely the rocker switch and connect

the motor wires to the control system. See the corresponding chapter below.

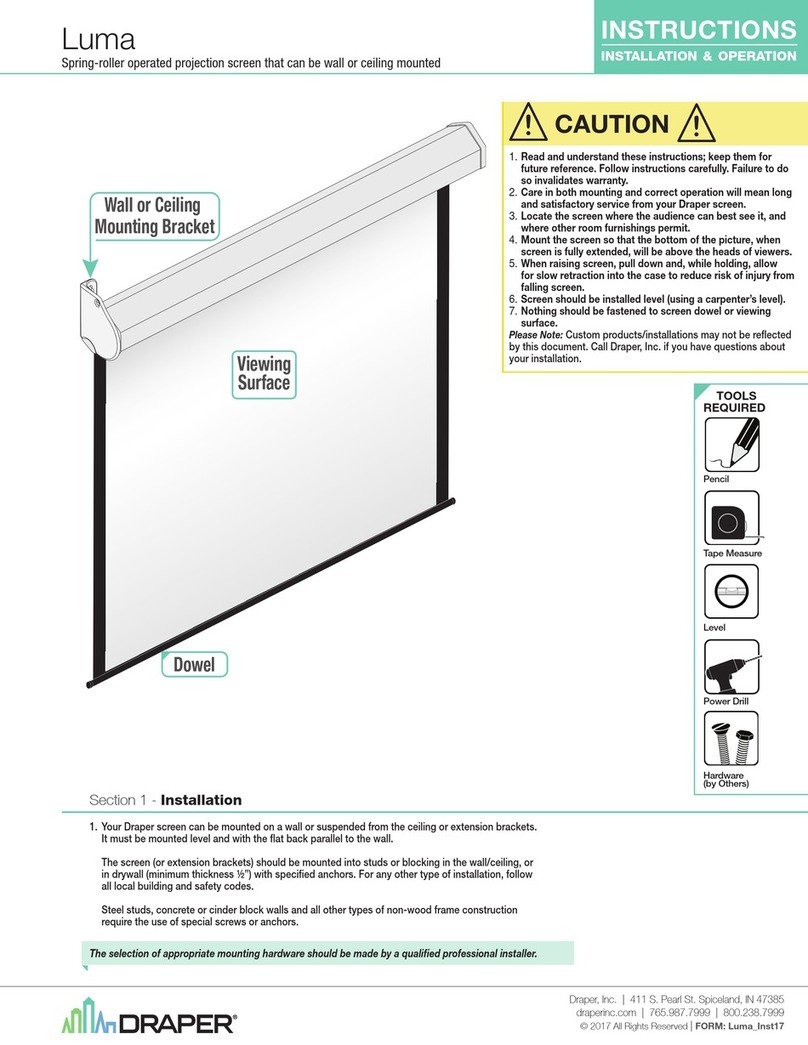

Ceiling Mount

1) Look on the top side (since it's a ceiling mount) and you'll see the metal DIN rail that will mount to the

wall. The front side of the rail is painted to matchyour case color. There are two screws fixing this into

the case for shipment. Loosenthese two screws to get the rail out and note

how the French cleat design works. You'll be doing the opposite on the

ceiling.

2) Locate the bag in the white remote box that has the five stainless steel

truss-head screws. These screws are intended for most standard ceilings

and wood joists. If you have a nonstandard ceiling type, just make sure that

you use appropriate load-bearing screws mounted into load-bearing

members. The DIN bar can accommodate up to #12 screws. The screen

weighs approximately 50-70 pounds, but you must make sure the mounting

technique you’re using is rated for at least 4 times that weight.

Mark where your DIN rail bar is to be mounted to the ceiling joists. Install

using the included SS screws (or your substitute). At least three screws,

securely mounted into your joists, are required. If you have a very curvy ceiling, you can space out a

screw or two with washers. You don't want the DIN rail to be curvy, or else the case won't engage all

the way.

Giving the DIN rail a little squeeze with pliers will narrow the distance the case needs to engage

onto, making it an easier mount.