Figure

5B- \

58-2

6C-

I

6C-2

.-,

'-2

'-2

,-.

.-,

.-s

.-,

.-.

8-10

8-11

8-

12

8-1 2

8-\3

8-14

8-\5

8-\6

8 -

17

8-18

FROST

MATTER

LIST

OF

ILLUSTRATI

O:-;S

(ConI)

Modol 28O/SP-14 OC

Control

Circuits

_

Simplified,

Modol 28O/SP-14

Tension

Control

Circui

t _

Simpllfied,

I

nterconnecting

Cabling

, Model 275

El

ec

:

ronlcs

Assembly

Panel,

."

lode

12

75

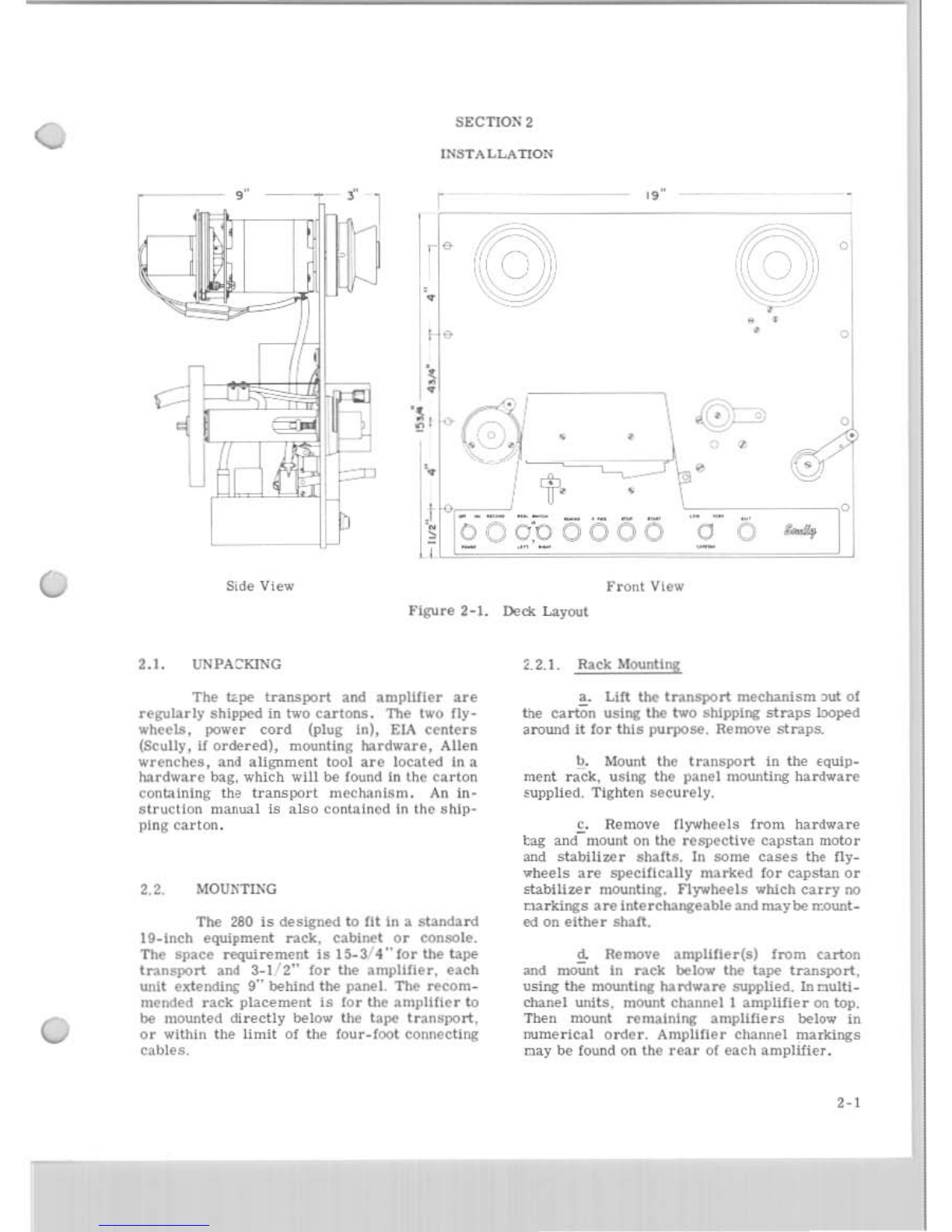

Side View of

Tape

Transport

. . . . .

Magnetic

Head

Assemb

ly, Expl

oded

Vi

ew

.

Tape

Break

Arm

Assembly

...

Auto:n

atic

Front

Shteld

Assembly

. .

Au\

o:natic

Tape

Lifter

Asse

mbly

OC PO"'er Supply,

Schematic

Diagram

Model 280

and

Early

Model

28O/SI'-14,

Power

and

Control

Circuits,

Schematic

Diagram

• . . . . . . . . . . . . . . .

Model 280 wi

th

Motion

Scnsing,

Po,,

'

er

and

Control

Circu!!s,

Schematlc

Dcagram . . . • • • . . . . . . . . . . , , . . . . . . .

Model 28O/SP-14, POwer

and

Contro

l

Circuits,

Schematic

Diagram

Mo,,",

l

28O/SP-14

with Motion

Sensing,

Power

and

Control

Circuits

,

Schematic

Diagram

. . . . . .

..

."...

Model 275

Reproducer,

Po,,-er

and

Con

lro

l

Ci;cuits,

Schematic

Diagram.

Elec

t

ronics

Schematlc

Diagram,

All

V

ersions

of M

odel

21)0

(Sheet J

01

2

Sheets).

.•..

....

.

..

..

. . . . .

Elec

t

ronics

Schematlc

Diagra

m,

All V

ers

i

ons

of

Moool 280 (Sheet 2

01

2She

e

tsl.

. . . . . . , • ,

....

.

..

.

Electronics

Circuit

Cards,

All Mooo is 280,

Parts

location

Diagram

Mode l 275

Electronics

Schematic

Diagram

.

Model 275

Electronics

Clrcu

il

Cards

,

Parts

Location

Diagrams.

Interconnecting

Ca ble

Schematic,

All

\Iodels

280 .

Model 275,

Interconn

ec

ting

Cable

Schematic

..

. .

Remote

Control

Unit,

Cat.

No, 504210100 -01.

Schematic

Diagram

(for Motion Sensi

ng

M

odels

280 a nd

280/SP-14)

.

""'-

6B-3

68-4

6C-2

6C-3

8-5/8_6

8-1/8-8

8-9/8-10

8-11/8_12

8-13/8-14

8-15/8-15

8-17(8-18

8-19/8-20

8-21/8·22

8-23/8-24

8-25

8-25

8-26

8-27

8-28

8-29/8-30

8-31/8-32

8-33/8-34

Iii