RRE2-A/101

3/27 rre2-a101_g_en_101

Contents History of revisions.........................................................................................4

Related documentation...................................................................................4

1. Introduction..........................................................................................5

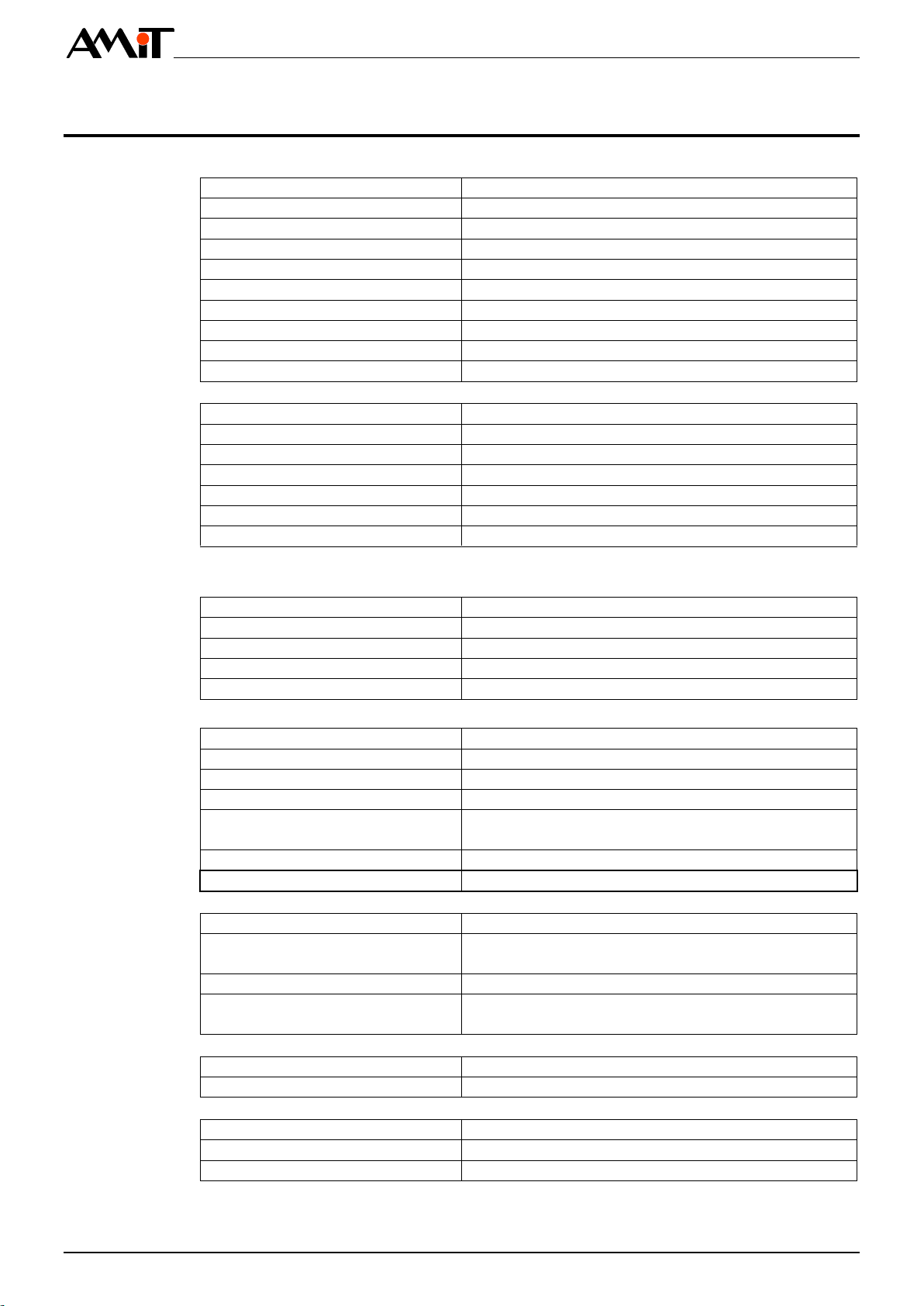

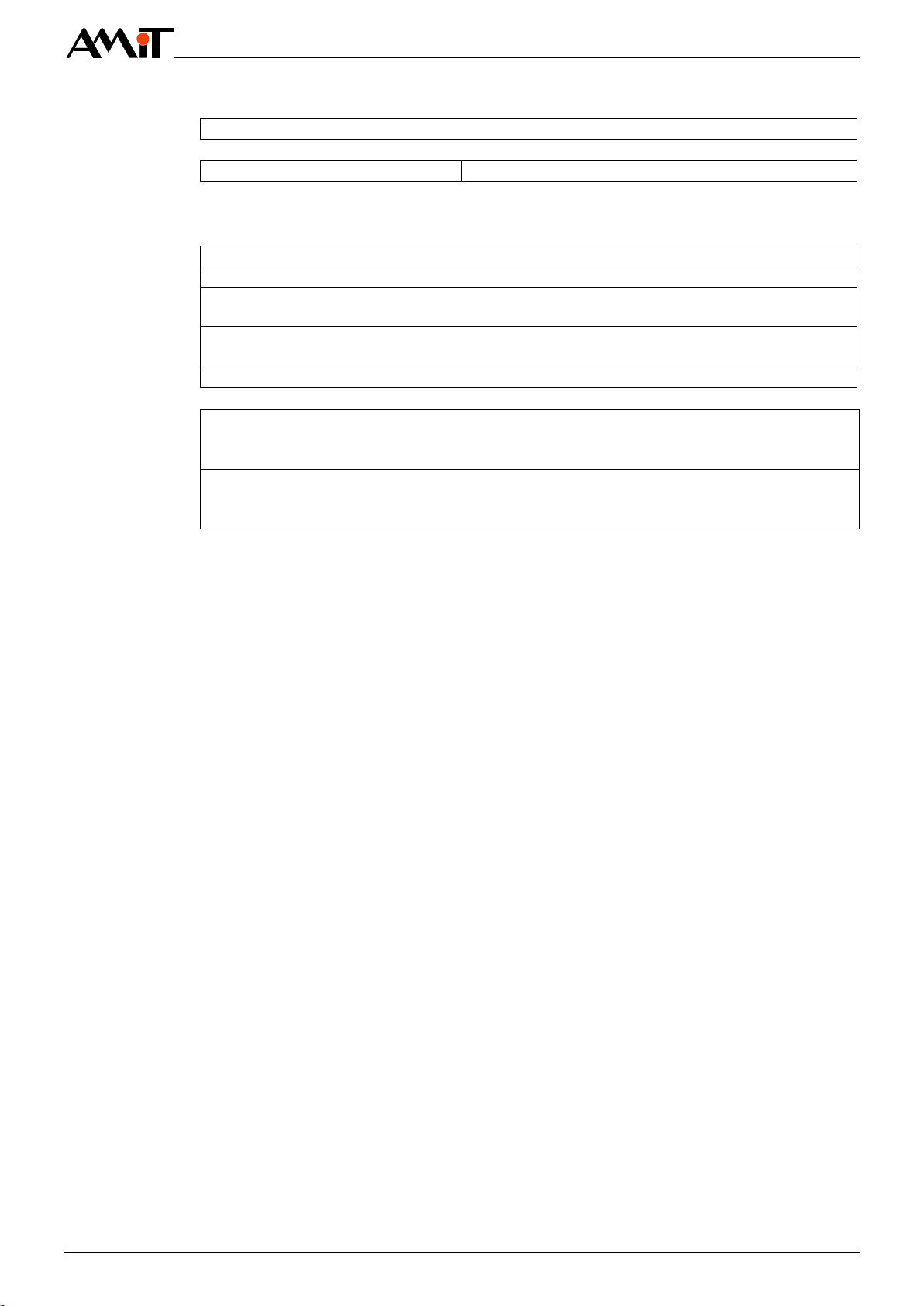

2. Technical parameters..........................................................................6

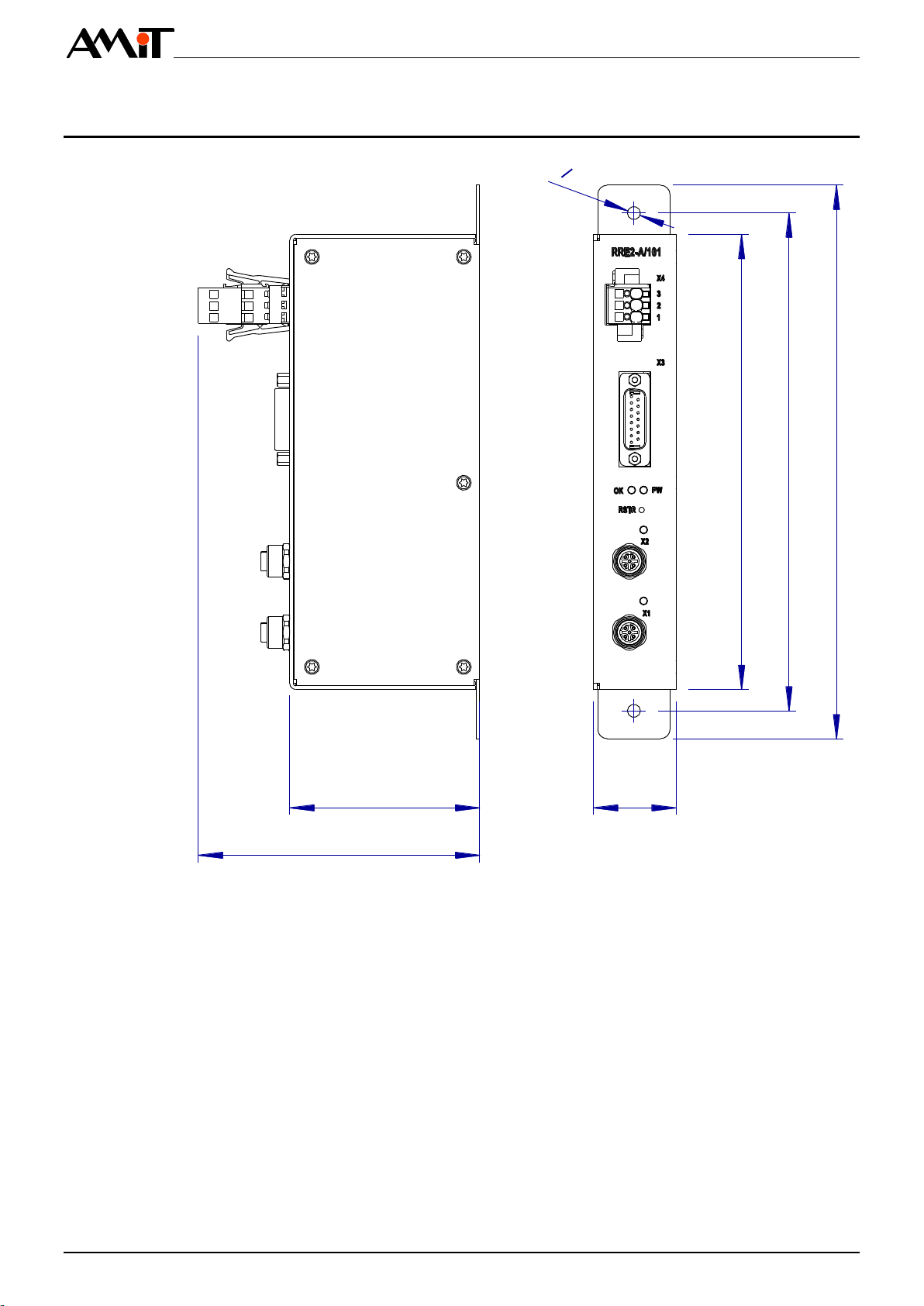

2.1. Dimensions.....................................................................................................8

2.2. Recommended drawing symbol .....................................................................9

3. Unit marking.......................................................................................10

3.1. Producer type label.......................................................................................11

4. Conformity assessment ....................................................................12

4.1. Other tests....................................................................................................12

5. Elements on the front panel..............................................................14

6. Power supply......................................................................................15

7. Inputs ..................................................................................................16

8. Ethernet...............................................................................................17

9. System LEDs......................................................................................18

10. Configuration .....................................................................................19

10.1. Factory setting..............................................................................................19

11. Mounting.............................................................................................20

11.1. Mounting instructions....................................................................................20

11.2. Mounting apertures.......................................................................................20

11.3. Installation rules............................................................................................21

12. Factory settings .................................................................................22

12.1. Software equipment......................................................................................22

13. Ordering information and completion .............................................23

13.1. Completion ...................................................................................................23

14.Packing ...............................................................................................24

15. Storing.................................................................................................25

16. Maintenance .......................................................................................26

17. Waste disposal...................................................................................27