Sea-Bird Scientific SBE 38 User manual

User manual

SBE 38 Digital Oceanographic

Thermometer

Document No. SBE38

Release Date: 2023-08-30

Version: A

Firmware: 2.0.0

425-643-9866

seabird.com

Table of Contents

Section 1 Safety information............................................................................................................ 3

1.1 Hazard information....................................................................................................................... 3

1.2 Equipment labels.......................................................................................................................... 3

Section 2 SBE 38 quick start guide................................................................................................ 5

Section 3 Specifications.................................................................................................................... 7

3.1 Mechanical................................................................................................................................... 7

3.1.1 Bulkhead connector............................................................................................................7

3.1.2 Dimensions..........................................................................................................................7

3.2 Analytical .................................................................................................................................... 7

3.3 Electrical ..................................................................................................................................... 8

Section 4 Set up sensor and verify operation.............................................................................. 9

4.1 Install software............................................................................................................................. 9

4.2 Set up and test RS232 communication........................................................................................ 9

4.3 Cable length and external power............................................................................................... 10

Section 5 Deployment and recovery.............................................................................................13

5.1 Data formats............................................................................................................................... 13

Section 6 Maintenance..................................................................................................................... 15

6.1 Clean bulkhead connectors........................................................................................................ 15

6.2 Examine O-rings........................................................................................................................ 16

6.3 Replacement parts..................................................................................................................... 16

Section 7 Command reference.......................................................................................................17

7.1 RS232 commands...................................................................................................................... 17

7.2 RS485 commands...................................................................................................................... 18

Section 8 Change interface............................................................................................................. 19

Section 9 General information....................................................................................................... 21

9.1 Warranty..................................................................................................................................... 21

9.2 Service and support................................................................................................................... 21

9.3 China RoHS disclosure table..................................................................................................... 21

1

Table of Contents

2

Section 1 Safety information

Please read this entire manual before this equipment is unpacked, set up, or operated.

Pay attention to all danger, warning, and caution statements. Failure to do so could result

in serious injury to the operator or damage to the equipment.

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury.

NOTICE

Indicates a situation which, if not avoided, may cause damage to equipment. Information that

requires special emphasis.

1.1 Hazard information

WARNING

This product can expose the user to chemicals with silica, crystalline (airborne particles of

respirable size), which is known to the State of California to cause cancer and birth defects or

other reproductive harm. For more information, go to www.P65Warnings.ca.gov.

NOTICE

The manufacturer is not responsible for any damages due to misapplication of misuse of this

product including, without limitation, direct, incidental and consequential damages, and disclaims

such damages to the full extent permitted under applicable law. The user is solely responsible to

identify critical application risks and install appropriate mechanisms to protect process during a

possible equipment malfunction.

1.2 Equipment labels

Read all labels and tags attached to the equipment. Personal injury or damage to the

equipment could occur if not observed. A symbol on the equipment is referenced in the

manual with a precautionary statement.

Electrical equipment marked with this symbol may not be disposed of in European domestic or public disposal

systems. Return old or end-of-life equipment to the manufacturer at no charge to the user.

EFUP: Hazardous material exists over the threshold of GB/T 26572.2011. The number in the center of

the symbol is the Environmentally Friendly Use Period as specified by SJ/T 11364-2014, China's

marking for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products.

This product should be recycled after its environmentally friendly use period.

3

Safety information

4

Section 2 SBE 38 quick start guide

This quick start guide gives the steps necessary to make sure that the SBE 38 sensor

operates correctly and collects data before it is deployed.

This quick start guide and user manual applies to both RS232 and RS485 models.

What's in the box:

• SBE 38

• CD—has software, calibration files, documentation

• I/O cable with 9V battery snap connector and battery.

1. Install the manufacturer-supplied software on a PC (refer to Install software

on page 9 for details.)

2. Connect the sensor to the PC and double-click on SeaTerm.exe to start the software.

3. Set up the sensor for deployment (refer to Set up sensor and verify operation

on page 9 for details.)

a. If necessary, make sure that all data stored in the sensor is transmitted to a PC.

b. Set the date and time (DateTime)

c. Configure the data collection settings.

d. Send the DS and DC commands to verify the setup.

e. For autonomous data collection, send StartNow to start operation immediately.

Send StartDateTime= or StartLater to start at a user-selected time in the future.

4. Immediately after the sensor is recovered from a deployment:

a. Use the software to turn off the sensor.

b. Rinse the sensor with fresh water.

c. Keep the sensor out of direct sunlight between deployments.

5. To store the sensor, flush the sensor thoroughly with clean water, then dry. Attach the

dummy plug.

5

SBE 38 quick start guide

6

Section 3 Specifications

3.1 Mechanical

Material Titanium

Depth rating 10,500 m

Weight in air, water 0.9, 0.5 kg

3.1.1 Bulkhead connector

Contact Function MCBH4MP

1 Ground

2 RS232 or RS485A RX

3 RS232 or RS485B TX

4 Voltage in

3.1.2 Dimensions

3.2 Analytical

Range -5 to 35 °C

Accuracy ±0.001 °C (1 mK)

Stability 0.001 °C (1 mK) in 6 months, certified

Resolution 0.00025 °C (0.25 mK)

Calibration -1 to 32 °C

7

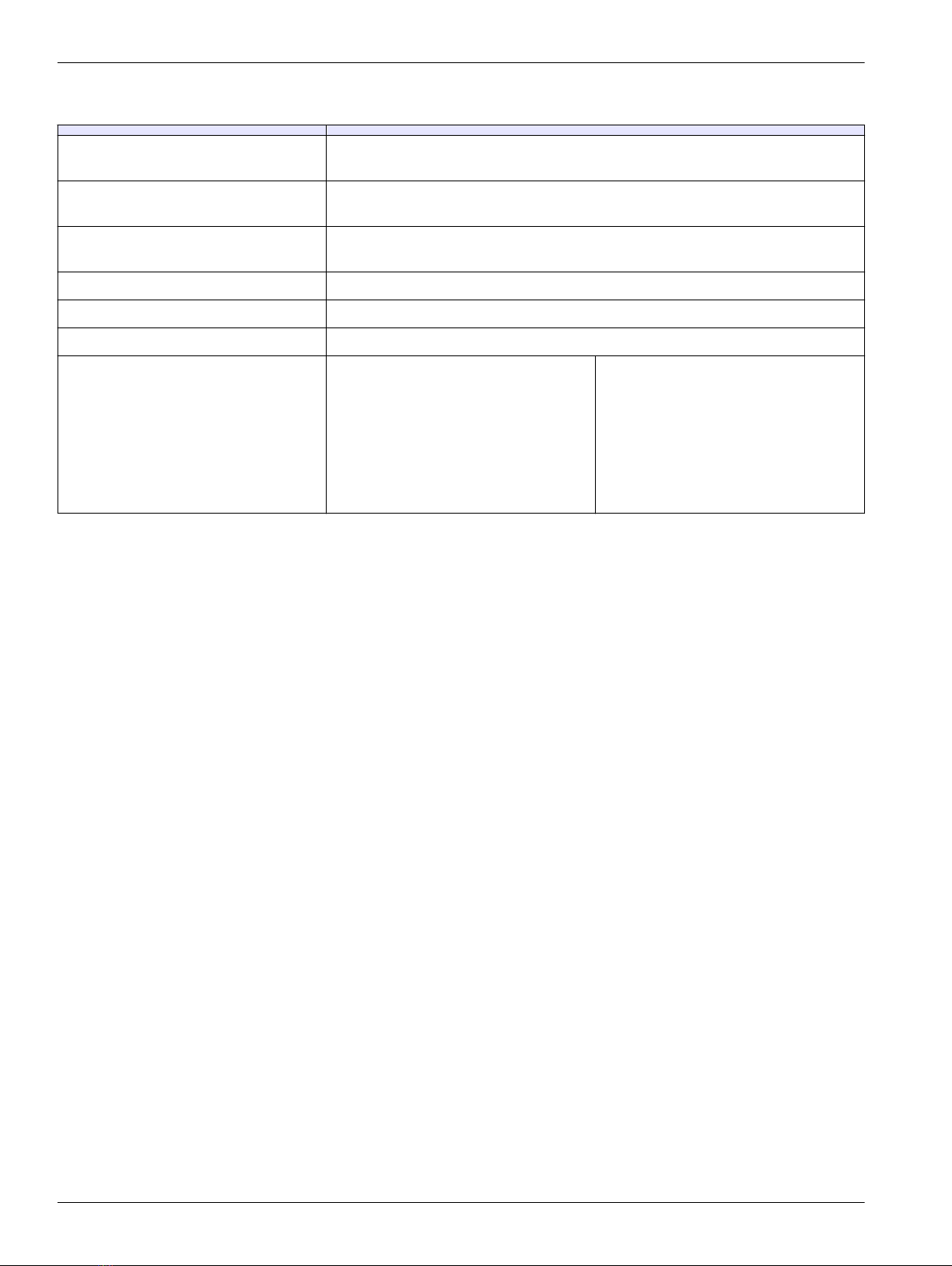

3.3 Electrical

External power RS232: 8–15 VDC @ 15 mA avg

RS485 half duplex: 8–15 VDC @ 10 mA avg

Current draw, data collection RS232: 6.3 mA @ 12 V (navg=1)

RS485: 3.5 mA @ 12 V (navg=30)

Current draw, low power RS232: 6.2 mA @ 12 V (navg=1)

RS485: 3.5 mA @ 12 V (navg=30)

Baud rates 1200, 2400, 4800, 9600 (default), 19200, 38400

Response time 500 msec

Self-heating error less than 200 µK

RMS noise, 8.5 °C

NAvg = number of A/D cycles per

sample.

Interval between samples, seconds =

(2/15 × NAvg) + 1/3

NAvg

1

2

4

8

16

32

Noise °C

0.000673

0.000408

0.000191

0.000133

0.000081

0.000052

Specifications

8

Section 4 Set up sensor and verify operation

The SBE 38 Digital Oceanographic Thermometer is a high-accuracy temperature

recorder that transmits real-time data in ASCII, in °C or in raw counts, through either an

RS232 or RS485 serial interface. The user can use a PC to see the data in real-time, and

it can be stored to a PC or data logger.

The SBE 38 operates in one of three ways:

• RS232 full duplex, with one SBE 38 connected to the interface

• RS485 half duplex, with one SBE 38 connected to the interface

• RS485 half duplex, with several RS485 sensors on one pair of wires.

When power is supplied, the SBE 38 reads its EEPROM, which includes calibration

coefficients and other setup information. The SBE 38 samples and transmits temperature

data continuously, or will wait for a command to start data collection.

The SBE 38 is frequently used as a remote temperature sensor with a SBE

21 thermosalinograph or a SBE 45 Micro thermosalinograph to get accurate sea surface

temperatures. Seasave and SBE Data Processing software can be used to see and

process the entire data stream when the SBE 38 is used with the SBE 21, SBE 45, or

SBE 16 or 19plus V2. If the SBE 38 is used with the SBE 25plus, data cannot be seen in

real-time.

Set up the hardware and install the software for the sensor to make sure that it operates

correctly before a deployment.

4.1 Install software

Make sure that the sensor is connected to the PC through the serial connector on the

supplied cable. A serial-to-USB adapter is necessary. Make sure that the USB driver

software is installed on the PC so that there is communication between the sensor and

the PC.

1. Install the SeasoftV2 software from the manufacturer-supplied CD.

2. Double-click on Seaterm.exe to start the launcher. If this is the first time the software

is opened, a SeaTerm Setup window opens. The software automatically connects at

the default baud rate of 9600 but will try others if necessary. The software

automatically looks for the serial port number of the connected sensor.

3. At the Instrument Type dropdown, select SBE 38.

4. Push OK to close this window.

The main window opens. The area on the top shows the menu of available

commands. The large area below shows commands and the responses from the

sensor to those commands.

4.2 Set up and test RS232 communication

Use the manufacturer-supplied cable to connect the sensor to the PC and a 9 V battery if

it is not already connected.

1. Start Seaterm.

2. From the Configure menu, select SBE 38 RS232.

Seaterm232 opens.

Table 1 Toolbar menu buttons

Connect enable communication with the sensor.

Disconnect the sensor so the COM port on the PC is available again.

Coefficients shows the calibration coefficients stored in the sensor.

Capture Capture sensor response on the screen to a file with a .cap extension. Push Capture again to turn off this function.

9

3. Change any settings in the SBE 38 Configuration Options window.

a. Select the applicable COM port.

b. Baud rate: 9600 is default.

c. Data bits: 8.

d. Parity: none.

e. Mode: RS232 or RS485.

f. Push OK to save the settings.

4. In the Communications menu, select Options/cycle baud when connecting.

5. Select Connect.

The software tries to connect to the SBE 38 at the baud rate set in Step 3.b. If it

cannot, it will try all other possible baud rates to try to connect. When it connects, the

display will show SBE 38 V 2.0.0 S/N xxxx then S>. If the user does not see the

S> prompt, select Connect again and make sure the correct sensor was selected in

the Configure menu and the settings were entered correctly in the Configuration

Options window. Make sure that the cable is connected correctly.

6. Select Status on the toolbar to see the SBE 38 status information:

SBE 38 V 2.0.0 S/N = xxxx

NAVG=1

Not sampling data

Automatically start sampling on power up

Default interface is RS-232

7. Enter TS then push Enter to take a sample.

If the output format was set to converted data (Format=C) with four digits to the right

of the decimal (Digits=4): 23.7658 shows, where23.7658 = temperature in °C. This

value should be approximately the ambient temperature. The SBE 38 is ready to

configure and deploy.

4.3 Cable length and external power

Calculate IR loss for real-time data collection for use with external power.

1. The communications IR loss should be 1 V or less when real-time data is transmitted.

The 38 will not transmit data if the IR loss is greater than 1V because of the

difference in ground potential.

2. Supply enough power so that sufficient power is available to the sensor after IR loss

is calculated.

Limit IR loss to 1 V to transmit real-time data

Maximum communications current draw × common wire resistance on the power wire =

limit to the length of the cable.

Vlimit = 1 V = IRlimit

Maximum cable length = Rlimit ÷ wire resistance/foot.

I = current required by SBE 38 = 15 mA for RS232, or 10 mA for RS485 (RS485).

Set up sensor and verify operation

10

Example 1:

What is the maximum cable length that can supply power to the SBE 38 with 18 gauge wire? Is the cable length the limiter at

1200 baud?

Rlimit = Vlimit ÷ I = 1 V ÷ 0.015 A = 67 ohms

Maximum cable length = 67 ohms ÷ 0.0064 ohms/ft = 10417 ft (3176 m)

3176 m > 800 m (maximum distance the SBE 38 can transmit data at 1200 baud) so IR loss is not the limiter for this

example.

Example 2:

Same as above, but with four SBE 38 sensors powered from the same power supply.

Rlimit = Vlimit ÷ I = 1 V ÷ (0.015 A × 4 SBE 38s) = 17 ohms

Maximum cable length = 67 ohms ÷ 0.0064 ohms/ft = 10468 ft (3190 m)

3190 m > 800 m (maximum distance the SBE 38 can transmit data at 1200 baud) so IR loss is not the limiter for this

example.

Table 2 Common wire resistances

Gauge Ohms/ft.

12 0.0016

14 0.0025

16 0.0040

18 0.0064

19 0.0081

20 0.0107

22 0.0162

24 0.0257

26 0.0410

28 0.0653

Table 3 Maximum cable length and baud rate

Length, m Baud rate

1600 600

800 1200

400 2400

200 4800

100 9600

50 19200

25 38400

16 57600

8 115200

To use the Seaterm232 software to see data in real-time, Select the Capture menu, enter

a file name, then push Save. This data file cannot be processed by Plot39 or SBE

Data Processing software because it does not have the required headers and format.

To process data with this software, transmit the data from SBE 39plus to a PC.

Supply sufficient power to 39plus

The power requirement depends on sufficient voltage at the power source after IR loss:

Set up sensor and verify operation

11

Example 1:

What is the maximum distance to supply power to the RS232 SBE 38 with 18 gauge wire and a 8.5 V power supply at

1200 baud?

The input power specification for the SBE 38 is 8–15 volts. A 0.5 IR drop would still supply enough power to the SBE 38.

V=IR

0.5 volts = 0.015 amps × (0.0064 ohms/foot × cable length) Cable length = 5208 ft (1588 m).

Note that 1588 m > 800 m, the maximum distance SBE 38 can transmit data at 1200 baud, so the IR loss does not limit the

distance.

Example 2:

Same as above but with four SBE 38 sensors powered from the same power supply

0.5 volts = (0.015 amps × 4 SBE 38s) × (0.0064 ohms/foot × cable length) Cable length = 130 ft (39 m).

Note that 397 m < 800 m, the maximum distance SBE 38 can transmit data at 1200 baud, so the IR loss limits the distance.

Use a higher voltage power supply or a 12 or 14 gauge wire to supply sufficient power.

Set up sensor and verify operation

12

Section 5 Deployment and recovery

Set up the sensor hardware for deployment. Make sure the SBE 38 is attached correctly

to any frame, and that all cables are attached correctly and the lock collars are tight. The

manufacturer recommends that the sensor is deployed with the thermistor end down to

keep sediment out of the thermistor.

Refer to the section on Cable length and external power on page 10 for details on the

correct length of cable to use.

Refer to the Command reference on page 17 section for details on specific commands

to control the SBE 38.

Use one of the sequences below to start data collection.

•AutoRun=Y: supply power to start to continuously collect data.

•AutoRun=N: send Go to start to continuously collect data immediately, or TS or TH

to take a single sample.

Deploy the SBE 38.

Recovery

WARNING

If the user thinks that a sensor has water in the pressure housing: Disconnect the

sensor from any power supply. Put on safety glasses and make sure that the sensor is

pointed away from the body and other people. In a well ventilated area, use the purge

port (if the sensor is so equipped), or very SLOWLY loosen the bulkhead connector to

let the pressure release.

To stop the SBE 38, push Enter, then send Stop, or remove power to the sensor. Make

sure to flush the SBE 38 with fresh water, then dry, and attach the dummy plug and lock

collar.

5.1 Data formats

Data from the SBE 38 is either converted or raw. Each line of data ends with a carriage

return and line feed.

Converted data

ttt.ttt

where t = temperature, °C.

The number of digits to the right of the decimal point is user-selected with the Digits=

command.

Raw data

nnnnnn.n

where n = counts

13

Deployment and recovery

14

Section 6 Maintenance

WARNING

If the user thinks that a sensor has water in the pressure housing: Disconnect the

sensor from any power supply. Put on safety glasses and make sure that the sensor is

pointed away from the body and other people. In a well ventilated area, use the purge

port (if the sensor is so equipped), or very SLOWLY loosen the bulkhead connector to

let the pressure release.

6.1 Clean bulkhead connectors

NOTICE

Do not use WD-40® or petroleum-based lubricant on bulkhead connectors. It will cause damage to

the rubber.

Damaged connectors can cause a loss of data and additional costs for service.

Damaged connectors can cause damage to the sensor and make it unserviceable.

Use silicone-based lubricants only.

Examine, clean, and lubricate bulkhead connectors at regular intervals. Connectors that

are not lubricated increase the damage to the rubber that seals the connector contacts.

The incorrect lubricant will cause the failure of the bulkhead connector.

1. Apply isopropyl alcohol (IPA) as a spray or with a nylon brush or lint-free swab or

wipes to clean the contacts.

2. Flush with additional IPA.

3. Shake the socket ends and wipe the pins of the connectors to remove the IPA.

4. Blow air into the sockets and on the pins to make sure they are dry.

5. Use a flashlight and a magnifying glass to look for:

Any corrosion.

Cracks, scratches, or other damage on the

rubber pins or in the sockets.

Separation of the rubber from the pins.

Swelled or bulging rubber pins.

6. Use a silicone-based lubricant on each of the contacts of the bulkhead connector.

The manufacturer recommends any of the products listed below.

• 3M™ Spray Silicone Lubricant (3M ID# 62-4678-4930-3). Make sure to let it dry.

• Dow Corning Molykote® III Compound (DC III)

• Dow Corning High Vacuum Grease® (DC 976 V)

15

• Dow Corning 4 Electrical Insulating Compound® (DC 4)

• Dow Corning Molykote 44 High Temperature Grease® (DC 44)

Use a finger to put a small quantity (approximately 1 cm in diameter) of silicone

grease on the socket end of the connector and push as much of the lubricant as

possible into each socket. Do not use too much lubricant, as that will prevent a good

seal.

7. Connect the connectors.

8. Use a lint-free wipe to clean any unwanted lubricant from the sides of the connectors.

6.2 Examine O-rings

NOTICE

Do not use petroleum-based lubricants on O-rings. It will cause damage to the O-rings.

Damaged O-rings can cause the sensor to flood and make it unserviceable.

Examine the O-rings on the sensor every time they are exposed—on the connector end

flange and other parts. O-rings must be pristine. If there is any question about whether an

O-ring is clean and undamaged, replace it with a new one.

1. Dry the O-rings and O-ring grooves with a lint-free cloth or tissue.

2. Examine each O-ring to make sure there is no damage, dirt, lint or hair on it.

3. Replace an O-ring if necessary.

4. Apply a small quantity of silicone-based Parker Super O Lube® or Dow Corning® high

vacuum grease to each O-ring.

• The lubricant helps the O-ring move into its groove with no twist, which can

compromise the seal.

• Do NOT use petroleum-based lubricants on any O-ring.

6.3 Replacement parts

Part

number

Description Application Quantity

231361 Plastic temperature sensor guard Attaches to end flange to protect temperature

sensor

1

30931 O-ring, Parker 2-214 N674-70 Install in end flange groove 1

801263 MCIL4FS to DB9S I/O cable with battery snap,

2.4 m

from SBE 38 to PC 1

171398.1 MCIL4FS dummy plug and lock collar Bulkhead connector protection 1

Maintenance

16

Section 7 Command reference

7.1 RS232 commands

Enter commands to the SBE 38 in upper- or lower-case letters and push Enter to send

commands. The SBE 38 sends ? CMD if an invalid command is entered.

If the sensor does not respond with an S> prompt when a command is sent, push Enter

to get the S> prompt.

Status

DS show status and setup parameters. Equivalent to Status on the software toolbar

Note: if the voltage is below 6.5 volts, the display shows WARNING: LOW BATTERY VOLTAGE!!

Setup

Interface=x x=232: RS232 interface

x=485: RS485 interface

Baud=x x= baud rate, default 9600. Supported rates: 1200, 2400, 4800, 9600, 19200, 38400

Format=x x=C: transmit converted data, °C

x=R: transmit raw data, counts

Digits=x x= the number of digits, 0–6, to the right of the decimal point for converted data. Applies only if Format=C

NAvg=x x= A/D cycles to average per sample, 1–127

AutoRun=x x=N or 1: wait for command when power is supplied

x=Y or 0: start continuous data collection automatically when power is supplied

Notes: • The baud rate sent to the SBE 38 must agree with the Seaterm software rate.

• The SBE 38 transmits data after it completes the previous and before it starts the next sample.

• To start data collection immediately after AutoRun=Y is sent, turn power off, then on again, or send Go.

Data collection

Go start continuous data collection now

Start

StartNow

start data collection

Stop stop continuous data collection

push Enter to get the S> prompt, then enter Stop

TS take one sample and transmit data

TSR take one raw (counts) sample

TH take one sample and hold data in the buffer

SH transmit data from the buffer

SL transmit data from last sample from the buffer

SLT transmit data from last sample from the buffer, then take one new sample and hold data in buffer

Notes: • To capture real-time data to a file, select Capture on the toolbar in the software and enter a file name. Do

this before you start data collection.

• If the voltage drops below 6.5 volts for ten consecutive scans during data collection, the SBE 38 stops and

sets the status to low battery.

• It may be necessary to send Stop several times to get a response from the SBE 38.

Coefficients

DC show calibration coefficients

17

CalDate=S S=temperature calibration date

A0=F F=temperature A0

A1=F F=temperature A1

A2=F F=temperature A2

A3=F F=temperature A3

Slope=F F=temperature slope, default 1.0

Offset=F F=temperature offset, default 0.0

F= floating point number. S= string with no spaces.

The date shown is the date the calibration date. Calibration coefficients are set by the manufacturer and should be the same

as the values on the Calibration Certificate for the SBE 38.

7.2 RS485 commands

It may be necessary to enter @@ before all commands to make sure the buffer is clear.

For example, S>@@#01DS.

Global

TxDelay=x x= delay after the SBE 38 transmits a response until the transmitter is disabled, 1–500 milliseconds Default 25

RxDelay=x x= delay after the SBE 38 receives a command until the transmitter is enabled, 1–500 milliseconds Default 25

GData command all SBE 38s to take one sample and hold the data in the buffer until they receive DATAii, SH, SL,

SLT, if #iiIDReq=N, or #iiSH, #iiSL,#iiSLT, if IDReq=Y

AData see above. GData and AData are the same, included for compatibility with RS485 MicroCATS

Get Data

Dataii transmit data from SBE38 with ID = ii, 0–99, when a GData or AData command was sent

ID Required

IDReq=Y use #ii, 0–99, before commands to individual sensors. Use this setting for systems with multiple

RS485 sensors on one pair of wires. IDReq=Y does not require #ii but subsequent commands to any sensor

do require #ii

#iiIDReq=N do not use #ii before a command to a single sensor. use this setting when there is only one SBE 38

IDReq=N does require #ii but subsequent commands to any sensor do not require #ii

ID (used when only on SBE 38 is online)

ID? show SBE38 ID, where ID = ii, and ii is 0–99, and whether ID is required before commands to a single sensor

*ID=ii set the SBE 38 ID to ii, 0–99. Send *ID= two times because the SBE 38 requests verification

if there is more than one RS485 sensor online when this command is sent, all sensors online will be

set to the same ID

Do not set AutoRun=Y on a system with more than one RS485 SBE 38 on a pair of

wires. Only one sensor at a time can transmit data in real-time on the RS485 interface.

Do not send Go to more than one RS485 sensor. The system cannot transmit a

command to one SBE 38 at the same time another sensor transmits real-time data.

To collect data continuously: if AutoRun=Y or Go is used, set NAvg= to a value greater

than or equal to 30.

Command reference

18

Table of contents