SEA COMPACT 400 User manual

Sistemi elettronici

di Aperture Porte e Cancelli

FITTING AND CONNECTION INSTRUCTIONS

ENGLISH

The Compact 400/800 consists of a hydraulic pump and a

hydraulic jack, both of which coupled in a supporting box

treated with cataphoresis.

The pump unit casing, which is used as an oil tank, contains the

electric motor, fluid pump, distributor and hydraulic oil.

It is also provided with an adjustable slowing-down device in

the two stop phases of the leaf .

The wheeling unit is composed by a double piston connected to

a rack which engages with the pinion of the leaf dragging shaft.

Gates up to 2 meters long can be securely locked using the

operators internal hydraulic locking system, thus ensuring

perfect keeping in closing and in opening.

For gate in excess of stated value: A hydraulic non locking

operator should be used in conjunction with a separate electrical

locking device to ensure keeping in closing.

For rotation angles not included between 90°-100 and 130°-

140° respectively, slowing down is either in closing or in

opening.

In case of power failure: The operator's internal hydraulic locking

can be released using a special key and the gate used manually.

(versions with slow-down only)

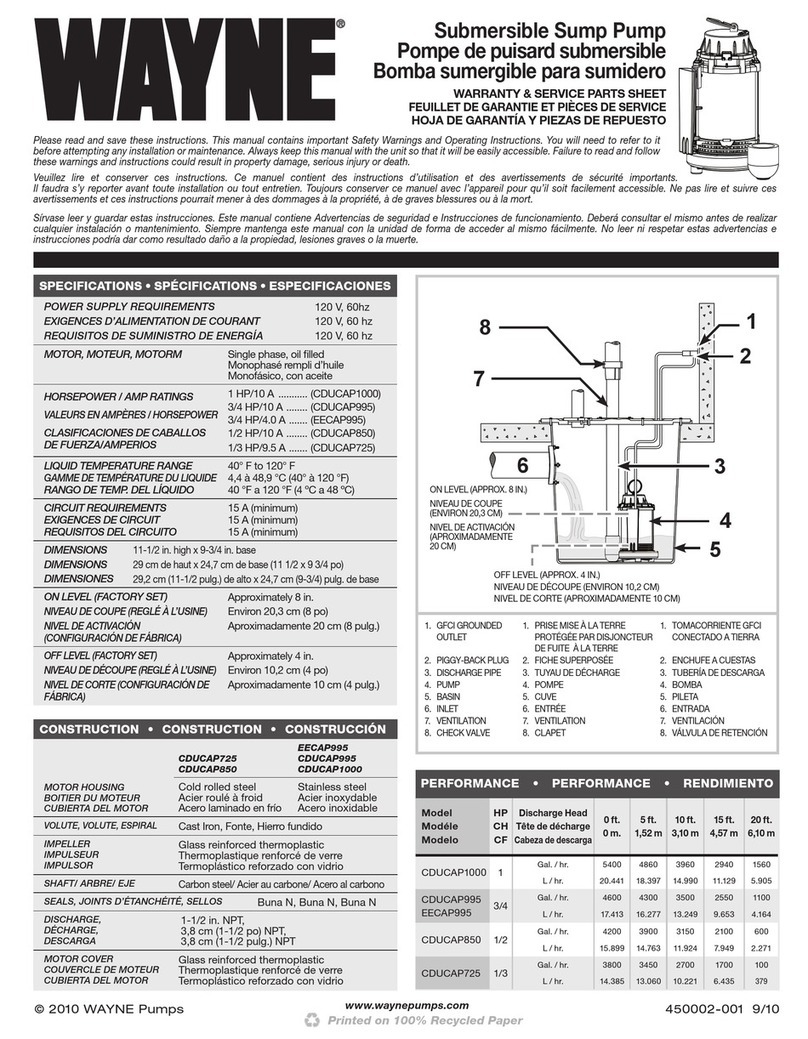

1Release Cover

2 Release Extention

3 Braking regulation screw

(where provided)

4 Exit hole for electric cables

5 By-pass regulation

Compact 400 Compact 800

230 V (±5%) 50/60 Hz

220 W

1,1 A

1400 rpm

45

50 bar

40 bar

-20°C +55°C

130°C

56 da Nm

12,5uF

13 Kg 13,8 Kg

IP55

400 Kg 800 Kg

Versions with slow-down

REV 02 - 09/2005

6Filling oil Cap

7 Oil level indicator

8Water draining hole

9Draining screw

10 Screw for braking regulation stop

MAIN PARTS NOMENCLATURE

1. GATE ARRANGEMENT

You must do some checks on the gate to see if fitting a

COMPACT system is possible:

A. (Make sure that) the fixed and moving parts of the gate are

strong and non-deformable;

B. the weight of each gate leaf must not exceed 400 Kg

(Compact 400), 800 Kg (Compact 800) ;

C. the hinges and general structure must be in good condition

and the gate must move smoothly throughout its travel;

E. as the limit switches are not provided within the actuator, it is

necessary to install mechanical limit switches stops to be fixed to

the ground in closing and in opening (Fig. 3).

D. the upper hinge alone is sufficient to install the unit; those

which are unnecessary can be eliminated (the lower and that in

the middle if exists);

DIMENSIONS (mm)

cod. 67410085

TECHNICAL DATA

Power supply

Motor Power

Absorbed current

Motor rotation speed

Cycles hour (with a 20°C temperature)

Max Pressure of the 0.50 lt pump in use

Max Pressure of the 0,75 lt pump in use

Operating temperature

Thermal protection intervention

Max torque

Starting capacitor

Weight

Protection class

Maximum weight of the gate

Braking regulation

11

22

33

44

55

66

77

88

99

1010

33

218

209

50

395 - 4 0*

4

2 meters

COMPACT

400

AC

4 meters

800 Kg

400 Kg

Max leaf weight Max leaf width

Underground hydraulic operators

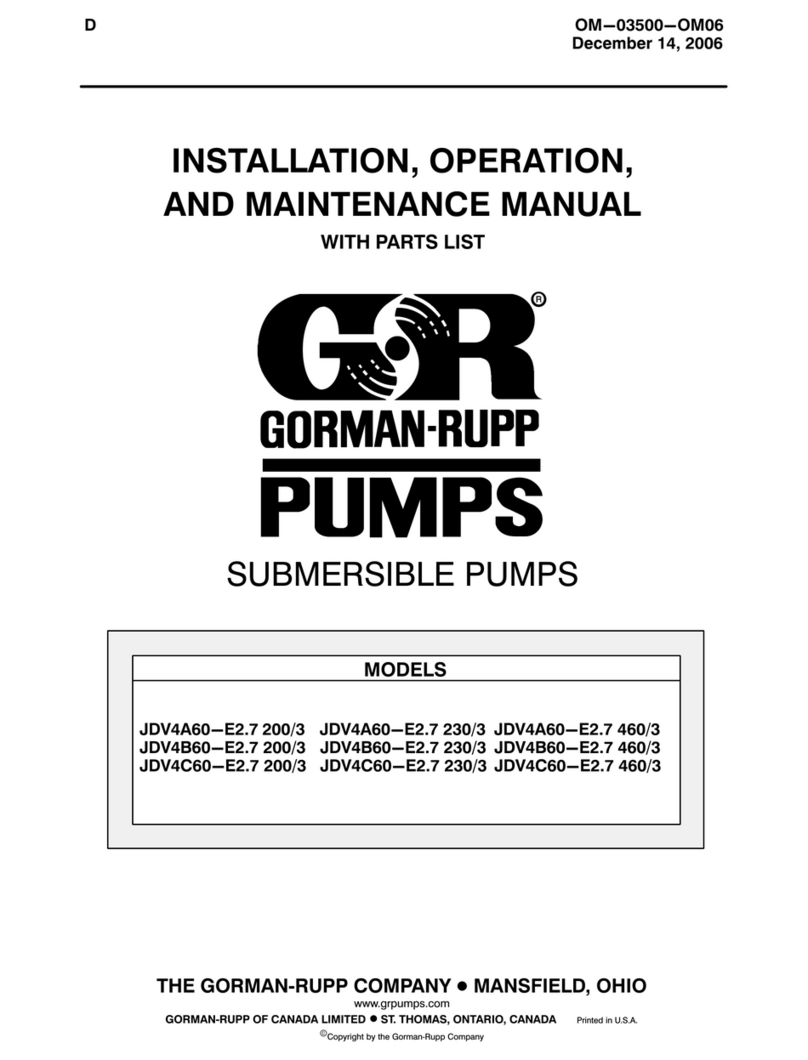

GRAPHIC FOR THE USE OF COMPACT 400

AND COMPACT 800 OPERATORS

COMPACT

400

AC

COMPACT 400 SB

(With electric lock)

COMPACT

400

SB (w.e.l.)

COMPACT

800 AC

COMPACT 800

AC

COMPACT 800 SB

(With electric lock)

COMPACT 800

SB

(With electric lock)

Fig. 1 * 180° version

Fig. 2

13/32

COMPACT 400 (with and without slowdown)

COMPACT 800 (with and without slowdown)

Sistemi elettronici

di Aperture Porte e Cancelli

Fig. 7

2.2. Inside the excavated pit you have to plan:

-rain water drainage;

-a water waste pipe in flexible plastic of about 40 mm of

diameter to put inside the provided hole of the box before it is

concreted (Fig. 5). It must be brought until the drain of the

sewer line;

-a sheath for the passage of electrical cables of about 20 mm

of diameter which must be brought to the proximity of the

electric connection box (Fig. 5).

Fig. 6

2. CARRYING BOX INSTALLATION

2.1. The hole which contains the carrying box must have the

approximate dimensions mentioned in Fig. 4.

For a correct placing, it is obbligatory to follow closely the quote

of 60 mm which corresponds to the minimum distance of the

rotation axis from the pillar.

Fig. 4

600 - 640*

450

220

* Compact 400 180°/Compact 800 180° box versions

dimensions (mm)

Fig. 3

Limit switch stop

in opening

Limit switch stop

in closing

2.3. Before concreting the carrying box, use a level to make it

perfectly horizontal to the ground (Fig. 6) and perpendicular to

the axis of the gate (Fig. 7).

The axis of the upper hinge of the gate must correspond exactly

to the axis of the carrying box shaft.

Follow the distance of 50 mm closely between the carrying box

cover and the base of the gate (Fig. 2) remembering that the U-

shaped iron will be inserted on it (see the paragraph 3).

Fig. 5

Sheath for electric

cables passage

Flexible pipe

for water draining

Electric

connection box

2.4. Put the jointed splined shaft into the upper hole of the

carrying box and fix it with the provided screw (Fig. 8)

Fig. 8

REV 02 - 09/2005cod. 67410085 14/32

Sistemi elettronici

di Aperture Porte e Cancelli

3. LEAFASSEMBLING

Before installing the gate make sure that the concrete has

hardened into the foundation hole.

3.1. Assemble the gate shoe which consists of a U-shaped iron

piece with a length of about 250 mm, which has an inside part like

the thickness of the leaf.

3.2. Place the bush on the U-shaped iron referring to the rotation

axis of the leaf hinge (Fig. 9);

Fig. 9

u-shaped iron

leaf rotation axis

bush

leaf

3.3. solder the bush carefully to the iron to closely follow the

perpendicularity with the rotation axis (Fig. 10)

NOTICE: The soldering waste must not fall on the operator, try to

protect it or solder away from it.

Fig. 10

Fig. 11

3.4. close off one end of the U-shaped by welding from the

post\pier side a suitable piece of plate.

3.5. Liberally grease the splined pinion on the box.

3.6. Put the U-shaped iron into the shaft of the carrying box.

3.7. Place the gate leaves on the U-shaped iron (Fig. 11) and

connect them to the hinges in the upper part.

It is important not to weld the gate leaf directly to the shoe.

3.8. Be careful not to place the leaf outside the axis (Fig. 12 and

13), but make sure the shaft corresponds to the hinge rotation

axis remembering that the minimum distance from the pillar is 60

mm (Fig. 14).

Fig. 12

Fig. 13

Fig. 14

REV 02 - 09/2005cod. 67410085 15/32

60 mm min.

Sistemi elettronici

di Aperture Porte e Cancelli

5. RELEASE SYSTEM

5.1. To release act as follows:

- Use the supplied key top surface to open the release cap which

protects the extention previously installed (Fig. 19)

- Put the key into the release extention and turn the handle of

about 180° anti-clockwise (Fig. 20)

- Take the key off and close the hole with the release cap.

5.2. To stop again act as follows:

- Use the supplied key top surface to open the release cap

- Put the key into the release extention and turn the handle

clockwise until it stops.

- Take the key off and close the hole with the release cap.

Fig. 19

Fig. 20

4.2. It is important to identify the right operator and the left

operator, in any case the release system must be always placed

inside the place of residence.

Make reference to Fig. 16.

inside part

outside part

release release

Fig. 17

4.3. Put the operator inside the carrying box by hand (Fig. 17)

and couple the pinion of the operator with the pinion of the box

using the jointed splined bush (Fig. 18).

Fig. 16

4. INSTALLATION OF THE OPERATOR

4.1. Before putting the operator into the carrying box, install the

release extention (Fig. 15).

Release

extention

Fig. 15

4.4. Carry out the electrical connections to the control unit as

described in the instructions supplied with SEAcontrol unit.

After ending all the operations in the installation of the above

mentioned carrying box, of the gate and the operator, try to do

some moves slowly by hand verifying that there are not irregular

frictions and that the movement is uniform for the whole range.

Notice: to do this last operation, release the operator as

described in the next paragraph.

Fig. 18

jointed

splined

bush

REV 02 - 09/2005cod. 67410085 16/32

Sistemi elettronici

di Aperture Porte e Cancelli

8. CABLE LAYOUT (Fig. 23)

9. RISK EXAMINATION

The points pointed by arrows in Fig. 24 are potentially

dangerous. The installer must take a thorough risk examination

to prevent crushing, conveying, cutting, grappling, trapping so

as to guarantee a safe installation for people, things and animals

(

).

Re. Laws in force in the country where installation has been

made.

Fig. 24

7. BRAKING REGULATION (where present)

7.1. It is possible to regulate the leaf slowdown in opening and in

closing, through the braking adjusting screw (Fig. 22).

7.2. To regulate slowdown operate as follow:

- Loosen the blocking screw of braking regulation

- Act on the adjusting screw clockwise to have a higher braking

and a speed decrease;

- Act on the adjusting screw anti-clockwise to have a lower

braking and a speed increase;

- After the regulation fix the blocking screw of braking

regulation.

For rotation angles not included between 90°-100 and 130°-

140° respectively, slowing down is either in closing or in

opening.

Braking regulation screw

Opening/closing

Fig. 22

Blocking screw for

braking regulation

1) Warning notice

2) Compact operator

3) Left photocell

4) Right photocell

8) Electronic control unit

9) Receiver

10) 16A-30mA differential switch

11) Electric lock (SB version only)

5) Key switch

6) Antenna

7) Flashing warning lamp

Fig. 23

5

4X1,

4X1,5

21

5

X,

X,

315

2X1,5

35

X1,

X1 5

3 ,

X1

1 ,5

2,

X

1

5

x5

1RG8

1

2

3

4

2

5

67

8

9

10

11

NOTICE

As for misunderstandings that may arise refer to your area distributor or call

our help desk. These instructions are part of the device and must be kept in

a well known place. The installer shall follow the provided instructions

thoroughly. SEA products must only be used to automate doors, gates and

wings. Any initiative taken without SEA Srl explicit authorization will

preserve the manufacturer from whatsoever responsibility. The installer

shall provide warning notices on not assessable further risks. SEA s.r.l. in

its relentless aim to improve the products, is allowed to make whatsoever

adjustment without giving notice. This doesn’t oblige Sea to up-grade the

past production. SEA s.r.l can not be deemed responsible for any damage

or accident caused by product breaking, being damages or accidents due

to a failure to comply with the instructions herein. The guarantee will be

void and the manufacturer responsibility (according to Machine Law) will

be nullified if SEA Srl original spare parts are not being used.

This is a

quotation from the GENERAL DIRECTIONS that the installer must read

carefully before installing. Packaging materials such as plastic bags, foam

polystyrene, nails etc must be kept out of children’s reach as dangers may

arise.

The electrical installation shall be carried out by a professional technician

who will release documentation as requested by the laws in force.

6. REGULATION OF THE PUSHING FORCE

The pushing force or anti-crushing force must be valued by hand

or better with a dynamometer and in both the ways of rotation.

To regulate such force act as follow:

act on the by-pass valves with the provided key clockwise to

increase the force, anti-clockwise to decrease it (Fig. 21).

The adjustment is carried out

with the gate moving and will

not change the speed of the

leaf.

Notice: The maximum

regulation is of 15Kgf

following the UNI EN 12453

law.

The motor run time is the last

adjustment to make. It

should be set 2 to 4 seconds

higher than it takes to the

gate to reach its stop. (this

last regulation must be done

on the electronic control

unit).

Fig. 21

REV 02 - 09/2005cod. 67410085 17/32

Sistemi elettronici

di Aperture Porte e Cancelli

DECLARATION OF CONFORMITY

SEAdeclares under its responsibility that the products

Compact 400, Compact 800

meet the essential requisites provided for by the following

European Directive and following changes:

89/392/CEE (Machine Directive)

89/336/CEE (Electromagnetic Compatibility Directive)

73/23/CEE (Low Tension Directive)

SAFETY PRECAUTIONS:

All electrical work should conform to current regulations. A 16 A

0,030 A differential switch must be incorporated into the source

of the operators main electrical supply and the entire system

properly earth bonded. Always run mains carrying cables in

separate ducts to low voltage control cables to prevent mains

interference.

INTENDED USE:

Compact 400 and Compact 800 undergrounded operators have

been designed to be used only for the automation of swing

gates.

SPARE PARTS:

To obtain spare parts contact:

SEAs.r.l. -Zona Ind.le, 64020 S.ATTO Teramo Italia

SAFETYAND ENVIRONMENTAL COMPATIBILITY:

Don’t waste product packing materials and/or circuits.

When being transported this product must be properly

packaged and handled with care.

MAINTENANCEAND OUT OF SERVICE:

The decommission and maintenance of this unit must only be

carried out by specialised and authorised personnel.

NOTE: THE MANUFACTURER CAN NOT BE DEEMED

RESPONSIBLE FOR ANY DAMAGE OR INJURY CAUSED

BY IMPROPER USE OF THIS PRODUCT.

SEA reserves the right to do changes or variations that may be

necessary to its products with no obligation to notice.

PERIODICAL MAINTENANCE

Check the oil level

(Trasparent cap n.7 in Fig. 1)

Change the oil

Verify the functionality of the by-pass valves

(check the force in opening and closing)

Check the release function

Verify the slowdown regulation (where present)

Verify the wear condition of the splined shaft

and of the splined bush

Check the correct drain of the rainwater

Check the integrity of the connection cables

Annual

2 years

Annual

Annual

Annual

Annual

Annual

Annual

All the above described operations must be made exclusively by

an authorized installer.

REV 02 - 09/2005cod. 67410085 18/32

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS JDV4A60-E2.7 200/3 Installation, operation and maintenance manual

Garland

Garland GEISER 491 FE instruction manual

Mindray

Mindray BeneFusion uVP Instructions for use

Wilo

Wilo VeroLine-IP-E Installation and operating instructions

Mouvex

Mouvex AK Series Installation, operation & maintenance instructions

Xylem

Xylem Ai1 Series product manual