11/19NT 1003-E00 09.12 AK O - AK I e

5. MECHANICAL SEALS (continued)

After opening the pump (see § 4.) :

To remove a taper lock shaft coupling

1. Dismantle the coupling of the pump.

For the standard coupling supplied by MOUVEX, loo-

sen the hexagonal socket head screws, and by repla-

cing one of them in the slot provided for this purpose to

release the tapered lock bushing.

For any other coupling, please refer to the supplier's

instructions.

2. Remove the shaft key 508.

To remove the bearing cover 705

1. Unscrew the screws 706 and washers 721.

2. Remove the bearing cover 705.

3. Check the condition of the lip seal 707.

To dismantle the front cover 401 of the pump (please

consider also to § 4.1)

1. Loosen the bolts 409 and nuts 409a.

2. Remove the front cover 401.

3. Remove the seal 403 and check its condition.

If the front cover does not easily separate, tap it lightly

with a plastic mallet to separate it progressively.

4. Extract the piston 301 (please also consider § 4.2).

To dismantle the bearing 703

1. Remove the circlip 704 using circlip pliers or a screw-

driver, taking care not to damage it.

2. Remove the washer 731.

3. Remove the shaft 501 from the bearing 703 by tapping

it lightly with the plastic mallet on the drive side of the

pump. Hold the shaft 501 firmly during dismantling.

4. Remove the protection circlip 733.

To dismantle the bearing cage 701

1. Separate the bearing cage 701 by tapping it with a

plastic mallet.

2. Remove the bearing cage seal 717 and check its condition.

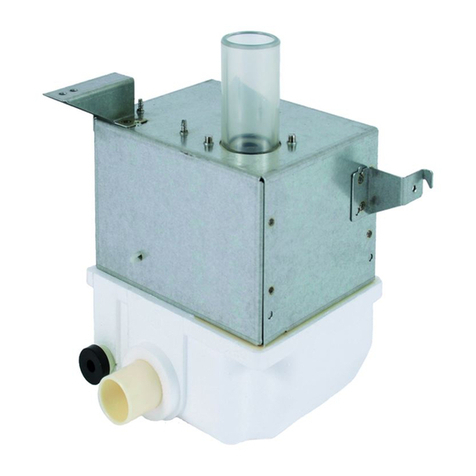

To dismantle the complete stationary part 610 of the

mechanical seal

1. Remove the stationary part of the mechanical seal 604

2. Remove the 'O' ring 605 from the holder and check its

condition.

To dismantle the rotating part 697

1. Remove the rotating part 697 from the shaft 501, taking

care not to scratch it (especially in the case of FEP

encapsulated 'O' rings. Check the condition of shaft sur-

face, rub it down with emery paper No 320 if scratched).

5.3 Assembly

Assembly of the rotating part 697

1. Mount the rotating part 697 on the shaft 501 (with the

assembly cone for the FEP 'O' rings) taking care not to

scratch the shaft (extremely important in the case of

the assembly of FEP 'O' rings. Check the condition of

the shaft surface, rub it down with emery paper No320

if scratched). Align the 2 lugs of the rotating part 697

with the 2 grooves on the shaft 501.

2. Clean the seal surface on the rotating part with a soft

cloth if it is dirty. Be careful not to scratch the surface

of the seal.

To assemble the complete stationary part 610 of the

mechanical seal

1. Clean the 'O' ring groove in the bearing cage 701.

2. Locate the 'O' ring 605 in the bearing cage 701.

3. Place the stationary part of the seal 604 in the bearing

cage 701, taking care to align the pin located in the rol-

ling bearing cage 701 with the groove on the stationa-

ry part of the seal 604.

4. Clean the surface of the seal with a soft cloth if it is

dirty. Be careful not to scratch the surface of the seal.

Assembly of bearing 703

1. Place the protection washer 733 in the bearing cage

701.

2. Position the shaft 501 with the rotating part 697 in the

bearing cage 701 with the washer 733.

Be careful not to knock the 2 surfaces of the seals.

3. Position the bearing 703 on the end of the shaft 501.

Tap the shaft lightly with a plastic mallet (NOT THE

PUMP DRIVE END).

4. Place the shaft 501 drive end up in a vice, resting on

the bearing cage 701, and tap on the inside of the bea-

ring 703 with the tube (the tube willl have an internal

diameter slightly larger than the internal diameter of the

ball bearing) and the plastic mallet until you see the cir-

clip groove 704 on the shaft. Be careful not to damage

the seal (tap lightly on the tube).

5. Assemble the washer 731 and the circlip 704 on the

shaft 501.

NOTICE : We recommend the use of a hand press.

Remounting the piston 301

Assembly of front cover 401

1. Clean the seal housing 403 and mount the seal 403.

2. Replace the front cover 401, taking care that the pis-

ton guide block is well assembled in its housing taking

care not to damage the seal 403.

3. Tighten the bolts 409 with the nuts 409a.

To assemble the rolling bearing cage 701

1. Clean the cage seal 717.

2. Assemble the cage seal 717 on the bearing cage 701.

3. Position the shaft 501 in the pump.

4. Fill the bearing 703 with grease (see § MAINTENANCE).

5. Reassemble the cover 705, grease the lip of the lip

seal 707 to ease assembly.

6. Replace the screws 706 and their washers 721.

697 comprising:

612

613

614

615

616

610 comprising:

604

605