Seagull 2C-LP427B User manual

1

XP-DT325B

4B-2053A

Thermal Barcode Printer

User’s Manual

Direct Thermal Printer

Please keep the user’s manual properly for reference

2C-LP427B

Contents

Copyright statement............................................................................................................................ 1

I. Product............................................................................................................................................. 2

II. Receiving........................................................................................................................................3

2.1 Unpacking and checking accessories............................................................................................3

2.2 Printer components.................................................................................................................... 4

2.2.1 Front view.................................................................................................................................. 4

2.2.2 Rear view................................................................................................................................... 4

III. Installation.....................................................................................................................................5

3.1 Install the printer........................................................................................................................... 5

3.2 Install the label.............................................................................................................................. 6

3.3 Install the external label holder - optional.................................................................................... 7

IV. LED indicator and button functions..............................................................................................9

4.1 LED indicator................................................................................................................................9

4.2 General button functions............................................................................................................... 9

4.3 Boot function.................................................................................................................................9

4.3.1 Gap/black mark sensor detection...........................................................................................10

4.3.2 Gap/black mark sensor detection, printing self-test value and entering the debugging mode11

4.3.3 Printer initialization............................................................................................................... 14

4.3.4 Skip the AUTO.BAS program............................................................................................... 15

V. Printer Diagnostic Tool...............................................................................................................16

5.1 Enable the Diagnostic Tool program........................................................................................ 16

5.2 Printer settings...........................................................................................................................17

5.3 Calibrate the paper sensor with the printer diagnostic tool...................................................... 18

5.3.1 Auto correction.......................................................................................................................18

VI. Troubleshooting........................................................................................................................ 19

6.1 Common problems....................................................................................................................19

VII. Simple maintenance procedures of the printer........................................................................23

Update history................................................................................................................................. 24

1

Copyright statement

Information in this subject to change without notice and does not represent a commitment on the part. No

part of this manual may be reproduced or transmitted in any form by any means, for any purpose other

than the purchaser’s personal use, without the expressed written permission..

2

I. Product

Thank you for purchasing our 4B-2053A series thermal barcode printer. This

desktop printer will provide you with safe, reliable and efficient printing at a reasonable

price. By using it, the roll labels can be printed in a wide range of texts or graphic formats.

Meanwhile, its superior function and easy operation make it your best choice among the

thermal barcode printers of the same level.

The 4B-2053A series printer provides thermal printing. The printing speed is

adjustable from 2.0, 3.0, 4.0, to 5.0 inches per second. It applies to a variety of printing

materials, including paper rolls, paper slices and fan-fold labels. In addition, the printer

has the built-in 1D and 2D barcodes that are commonly used, a TTF font and eight sets of

English numeric fonts in different sizes, and supports printing in 4 different directions.

And through the zoom function, the fonts can be enlarged. All these will enable you to

improve the label printing efficiency significantly.

3

II. Brief

2.1 Unpacking and checking accessories

This printer is specially packaged to protect against possible damage in transit. However,

since the printer may still be subjected to unexpected damage during transportation, you are

kindly required to check the packaging and all units carefully when receiving the printer. In

case of obvious damage, please contact the sales dealer directly and indicate the severity of

the damage. If necessary, you should keep the packaging materials for returning the printer.

Once you have received your barcode printer, place it on a clean, steady table and carefully

remove the packaging material. Check if the following items are included:

One printer x1

One disk x1

One paper roll shaft (1" core) x1

Two baffles for paper roll shaft x2

One USB cable x1

One power cord x1

One copy of quick installation guide x1

Dealer's options:

WIFI (factory optional)

Bluetooth (factory optional)

User's options:

External paper roll holder (O.D. 214 mm with 1" or 3" core)

Bushing of paper roll shaft: 1.5", two x2

4

2.2 Printer components

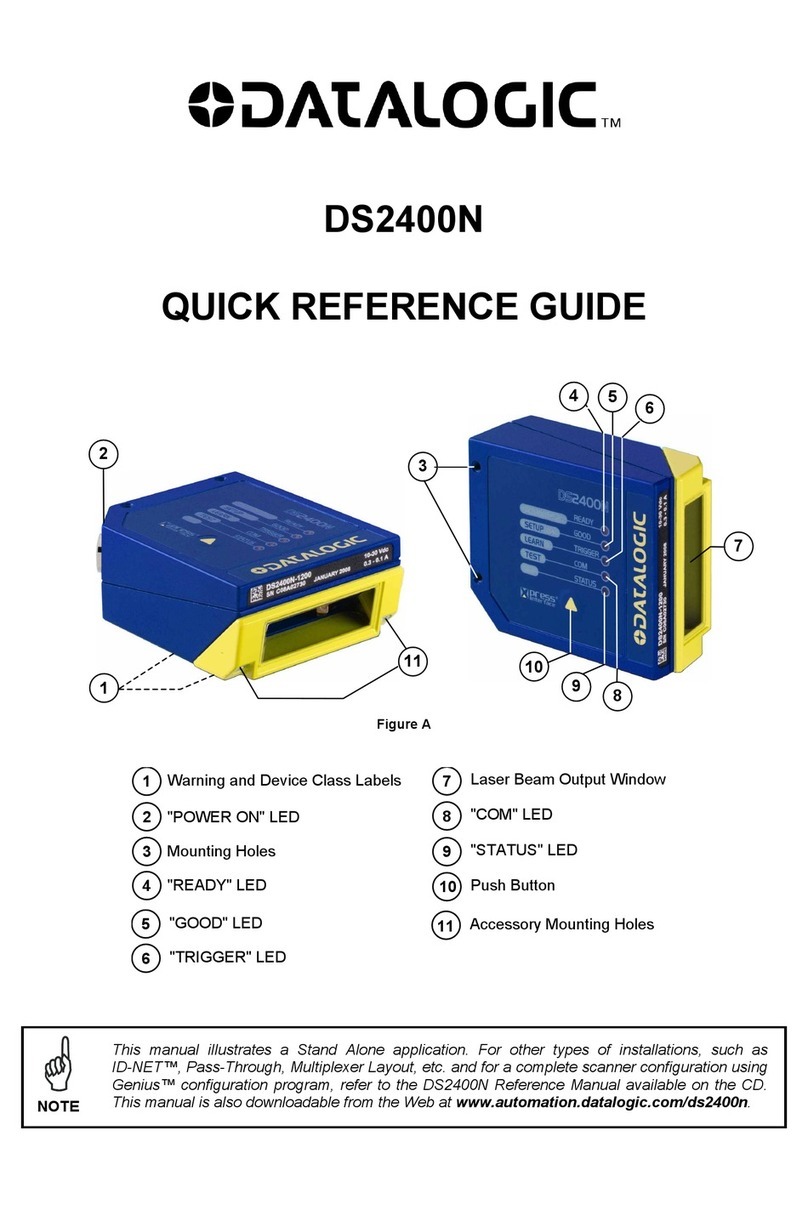

2.2.1 Front view

2.2.2 Rear view

1.

Power switch

2. USB interface

3. Power interface

Note: The transmission interfaces of the printer in the picture will vary depending on the model

of machine you purchase. For the actual transmission interface, please refer to the catalog

specifications.

Paper exit

Printer cover

Hook for cover

LED

Feed

Pause

Transparent lid

123

5

III. Installation

3.1 Install the printer

1. Place the printer on a smooth surface and make sure the power is off.

2. Plug one end of the parallel port cable, serial port cable or USB cable into the slot on the

back of the printer, and connect the other end of the cable to the appropriate slot of your

computer.

3. Plug the power cord into the power slot on the back of the printer and plug the other end

into an AC socket.

Note: Make sure the printer power is switched off when you plug the power cord into the

power slot on the back of the printer

6

3.2 Install the label

1. Insert the paper roll shaft into the paper roll and insert it into the paper roll shaft bushing.(*If

the paper roll you are using has a core of 1 inch, remove the 1.5" paper roll shaft bushing, and

simply use the paper roll shaft only.)

*1.5"纸卷轴榇套

纸卷

打印面朝上

纸卷轴

固定片

2. Push the printer cover release button forward with both hands to open the printer cover.

3. Place the label roll on the label roll holder. (Print side up)

4. Pass the label through the paper guide and pull the label over the rubber roller.

Print head

Paper guide

Rubber roller

1.5” Paper roll

shaft bushing

Print side up

1’’ Paper roll shaft

Paper roll

Fixing piece

Printer cover

Label holder

7

5. Close the printer cover.

Note: To avoid poor printing quality, make sure the printer cover is closed tightly.

3.3 Install the external label holder - optional

1. Fix the external label holder on the bottom of the printer.

2. Place the label roll on the external label holder.

External label holder

8

3. Push Hook for cover forward with both hands to open the printer cover.

4. Route the label from the external paper feed through the external paper guide and into the

printer.

5. Pass the label through the paper guide and pull the label over the rubber roller.

6. Turn the knob so that the paper guide has the same width as the label and contacts slightly the

label.

7. Close the printer cover.

External paper feed

9

IV. LED indicator and button functions

This series of models is equipped with 2 sets of gear drive motors that can handle 300 printers. It

has one button and one indicator that can display three colors. Pressing the button in conjunction

with different colors or collaborating with the power switch will enable the printer to start multiple

functions, such as: feeding paper, pausing the printer, calibrating the label, printing the self-test

value, initializing the printer, etc., Details are described as follows.

4.1 LED indicator

LED indicator color

Description

Blue (fixed)

Power on, printer standby to print

Blue (flashing)

The printer is downloading data or the printer is paused

Purple

The printer is clearing data

Red (fixed)

The printer cover is opened

Red (flashing)

Printing errors occur, such as: out of paper, paper jam, or

memory error, etc.

4.2 General button functions

1. Paper feeding

When the printer is ready (LED blue fixed), click the button and the roll label will advance to

the front of the next label paper.

2. Pausing of printing operation

While the printer is printing, clicking the button will pause the operation. At this point, the

power indicator light flashes blue. Click the button again to resume the printing.

4.3 Boot function

This printer has four boot functions that can be used to set or test the printer's hardware. These

functions can be activated by holding down the button and releasing it with the light signal when

the machine is started.

Please follow the steps below to start the boot function:

1. Turn off the printer.

2. Turn on the printer while holding down the button.

3. Release the button with the light signal indicating the required function, as listed in the table

below.

Boot function

Indicator color cycle mode:

Indicator light signal

Function

Purple

Blue

Red

Purple

Blue

Blue

(Flashing 5 times)

(Flashing 5 times)

(Flashing 5 times)

(Fixed blue)

1. Gap/black mark sensor detection

Release the button

2. Gap/black mark sensor detection,

printing self-test value and entering the

debugging mode

Release the button

3. Printer initialization (restore factory

defaults)

Release the button

4. Skip the AUTO.BAS program

Release the button

10

4.3.1 Gap/black mark sensor detection

This test aims to determine the sensitivity of the label paper sensor after the printer is turned on. When

the user installs a new paper roll of a different specification or initializes the printer and restores it to

the factory default value, the label paper gap sensor needs to be re-measured. The gap detection or

black line mark calibration will be completed with your last set value as the reference value. The

default value of this printer sensor is set to gap calibration.

Please follow the steps below:

1. Turn off the printer

2. Turn on the printer while holding down the feed button

3. When the indicator light flashes red after the first purple, release the feed button

Indicator color cycle mode:

Purple Blue Red (flash 5 times) Purple (flash 5 times) Blue (flash 5 times) Blue (fixed)

Note:

Whether the printer roll label sensor detects the gap or the black mark depends on the GAP or BLINE

commands sent to the printer (with your last set value as the reference value, the default value of the

printer sensor is set to gap calibration); for more information on GAP and BLINE commands, please

refer to the TSPL2 programming manual

11

4.3.2 Gap/black mark sensor detection, printing self-test value and entering the

debugging mode

This test aims to determine the sensitivity of the label paper sensor after the printer is turned on.

When the user installs a new paper roll of a different specification or initializes the printer and

restores it to the factory default value, the label paper gap sensor needs to be re-measured. The

gap detection or black line mark calibration will be completed with your last set value as the

reference value. The default value of this printer sensor is set to gap calibration.

Please follow the steps below to calibrate the label paper by the sensor:

1. Make sure that the label paper is properly installed

2. Turn off the printer

3. Turn on the printer while holding down the feed button

4. When the indicator light flashes purple after the first purple, release the feed button

Indicator color cycle mode:

Purple Blue Red (flash 5 times) Purple (flash 5 times) Blue (flash 5 times) Blue (fixed)

5. The sensor will calibrate the label paper and the printer will print out the self-test value, and

finally enter the debugging mode and print out the value

6. Turn the machine off and on again to return the printer to the normal printing mode

Note:

Before carrying out the label paper sensor calibration, first confirm the type of label to be detected

with Diagnostic Tool or GAP/BLINE commands. For more information on GAP and BLINE

commands, please refer to the TSPL2 programming manual

12

Self test

When the sensor calibration is completed, the printer prints out the self-test value. Before connecting the

printer to your computer, you can use self-test to confirm that the printer is functioning properly. The

printed self-test value can be used to check the printing quality of the print head and to know the internal

settings of the printer.

Printer internal settings printed in the self-test mode

Model & firmware version

Machine serial number

Print head mileage

Check code

Serial port setting

Character set

Country code

Printing speed

Printing density

Paper size (width, height)

Black mark or gap size (vertical gap,

offset)

Sensor strength

Ethernet setting

information (optional)

Stored file information

Print head

check sample

13

Debugging mode

After the self-test is printed, the printer system enters the debugging mode. In the debugging mode, all

roll labels will be printed in machine code. The ASCII strings on the left are the data received by the

system. The data on the right are printed from the strings on the left, in hexadecimal values. This

function is provided for users or engineers to debug programs. You only need to turn off and on the

power again to leave the debugging mode and return to the normal printing mode.

ASCII string

Hexadecimal value

data corresponding to

the ASCII string listed

on the left

14

Note:

1. A4"wide label paper is required to print all debugging mode data

2. Turn off and on the power to leave the debugging mode and return to the normal printing

mode, or press the FEED button to return to the standby state.

4.3.3 Printer initialization

The printer initialization function is to clear the downloaded files in the memory (DRAM) and restore

the print parameters to the factory default settings.

Please follow the steps below to complete the initialization:

1. Turn off the power

2. Hold down the feed button and turn on the power. At this point, the power indicator light color will

cycle as follows

Indicator color cycle mode:

Purple Blue Red (5 flashes) Purple (5 flashes) Blue (5 flashes) Blue (fixed)

3. Release the feed button when the power indicator is flashing blue. At this point, the printer will be

reset, and then the power indicator will flash purple once, and finally the indicator will be blue

ready.

After initialization, the printer configuration is restored to its default values as follows:

Parameters

Defaults

Speed

127 mm/sec (5 ips) (203DPI)

Density

8

Label width

3.15” (80 mm)

Label height

7.9” (180 mm)

Sensor type

Gap sensor

Gap setting

0.16” (4.0 mm)

Printing direction

0

Reference point

0,0 (upper left corner)

Offset

0

Tear-off mode

On

Peel-off mode

Off

Characters

850

Country code

001

Clear flash

No

15

4.3.4 Skip the AUTO.BAS program

The TSPL2 command language allows the user to load an auto-execute file (AUTO.BAS) into the

flash memory. When the printer is turned on, it will be automatically executed according to the file

loaded by the user. When you want to skip the AUTO.BAS after power-on, you can use this boot

function to ignore this auto-execute file.

Please follow the steps below to skip AUTO.BAS:

1. Turn off the power.

2. Hold down the feed button and turn on the power. At this point, the power indicator light color

will cycle as follows.

Indicator color cycle mode:

Purple Blue Red (5 flashes) Purple (5 flashes) Blue (5 flashes) Blue (fixed)

3. Release the FEED button when the indicator light is fixed blue.

4. The printer will skip the AUTO.BAS program.

16

V. Printer Diagnostic Tool

Diagnostic Tool is an easy-to-use window-type utility program that allows you to check the current

status and settings of the printer, download graphic files, programs, font files, etc., and complete

firmware updates according to the actual need. Moreover, it supports creation and download of

dot-matrix fonts, transmission of commands or files and so on. By using it, you can complete the

printer setup, check the printer status and troubleshoot the printer usage problems more easily.

5.1 Enable the Diagnostic Tool program

1. Move the mouse cursor to the Diagnostic Tool image and double click the

left mouse button.

2. After it is started, the main screen shows 4 management pages (printer settings, file

management, communication tools, system printer settings).

17

5.2 Printer settings

1. Select the connection interface between your computer and the printer.

The default communication interface of

this printer diagnostic tool program is

USB, so if the computer is connected

through USB cable for transmission, no

changes need to be made to the settings

2. Click on a function you intend to set in the "Printer Settings".

3. The printer functions in the Printer Settings management page are described as below.

Description

Sensor Calibration

Set Ethernet network

Set Printer RTC Time Parameters

Restore Factory Defaults and Reboot

Restart the Printer

Print Test Page

Print Self-test Page

Enter Printer Debugging Mode

Ignore the AUTO.BAS File

Set the Diagnostic Tool Password

18

5.3 Calibrate the paper sensor with the printer diagnostic tool

5.3.1 Auto correction

1. Make sure the paper is installed correctly and the print head is closed.

Note: The paper sensor of this model is adjustable. Please make sure that the gap or black mark of

the paper will pass through the triangle symbol of the gap sensor (gap sensor position)or the

black mark sensor

Gap sensor

Black mark sensor

2. Turn on the printer.

3. Start the Diagnostic Tool and set the transmission interface (the default is USB).

The default communication interface of

this printer diagnostic tool program is

USB, so if the computer is connected

through USB cable for transmission, no

changes need to be made to the settings

4. Click on "Sensor Calibration".

5. Select the paper type and click on "Calibration". The printer will automatically feed the paper

to calibrate the sensor.

Gap sensor

Gap sensor

Mark sensor

Mark sensor

This manual suits for next models

1

Table of contents