INSTRUCTIONS FOR:

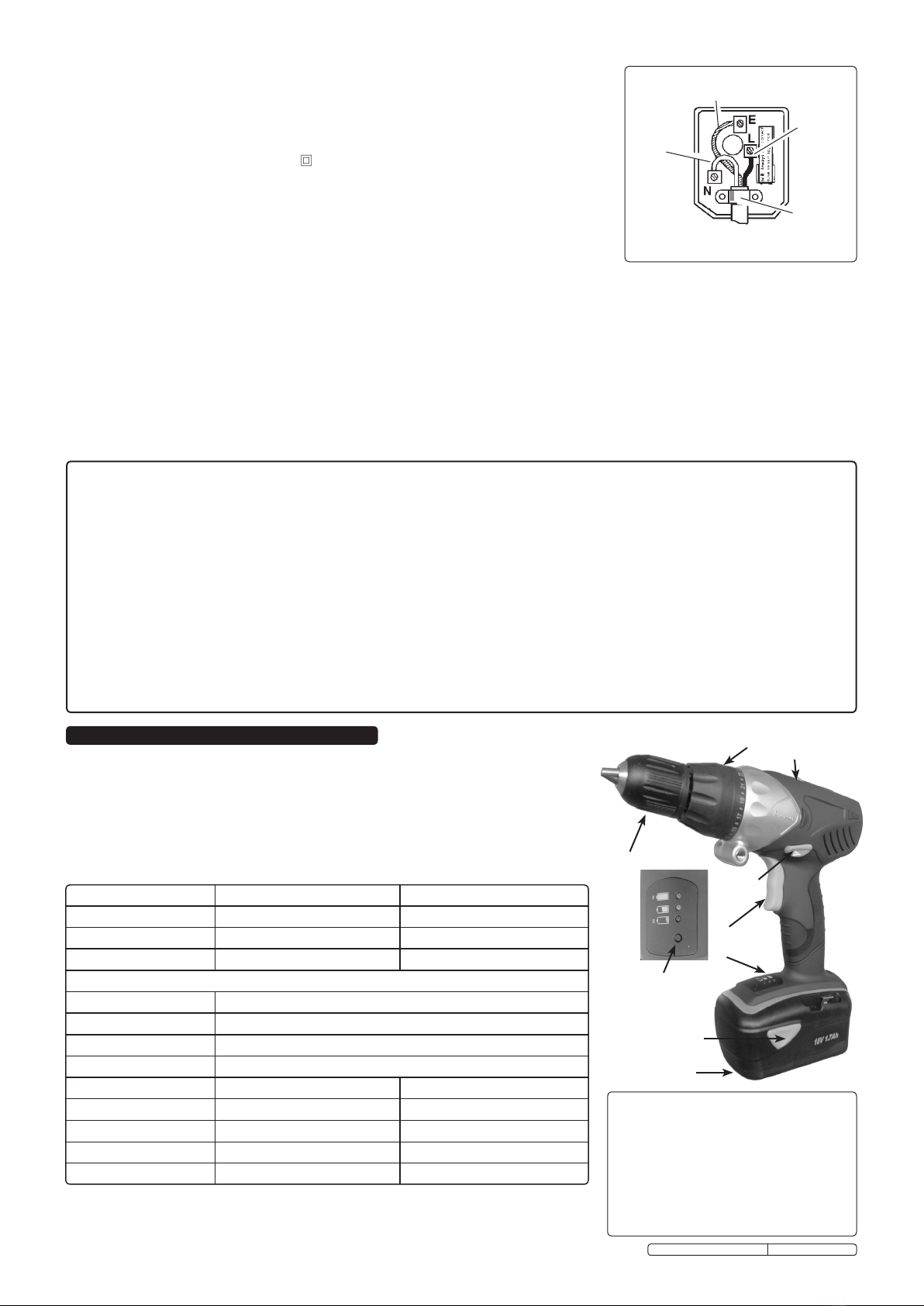

CORDLESS HAMMER DRILL/DRIVER

14.4V/18V SUPER TORQUE

MODEL Nos: CP3014VHK & CP3018VHK

Thank you for purchasing a Sealey product. Manufactured to a high standard this article will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND

CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY.

PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1.1. GENERAL SAFETY

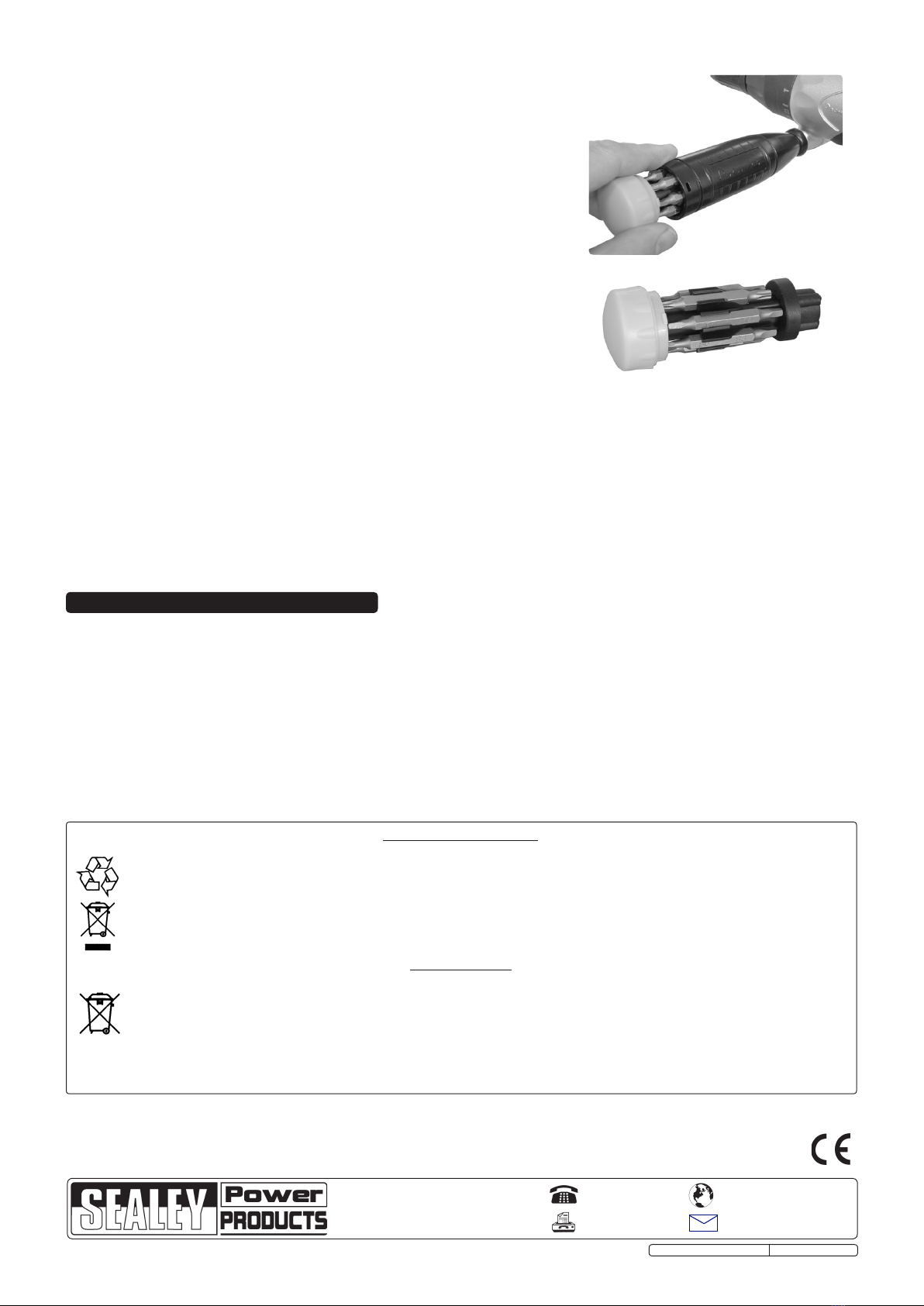

Remove the battery pack from the drill before servicing or performing any maintenance.

Maintain the drill and battery pack in good condition.

Replace or repair damaged parts. Use an authorised service agent and recommended parts only. Unauthorised parts may be

dangerous and will invalidate the warranty.

Ensure that the drill is switched off before installing the battery pack.

Keep the drill, battery pack and charger clean for optimum performance.

Remove ill fitting clothing. Remove ties, watches, rings, any loose jewellery and contain long hair.

Evaluate the work area before using the drill e.g. ceiling, floors and enclosures may contain electrical items or water piping.

Ensure battery pack is correctly inserted onto the drill handle and latched in place before switching on drill.

Secure loose workpieces with a clamp, vice or other adequate holding device. DO NOT hold workpiece in your hand.

Avoid unintentional starting.

Wear approved safety eye protection (standard spectacles are not adequate).

Maintain correct balance and footing. Ensure that the floor is not slippery and wear non-slip shoes.

Be aware that this drill does not need to be plugged into the mains power.

Keep chuck direction switch in the locked position until the drill is required for use.

Keep children and unauthorised persons away from the working area.

DO NOT use the drill where there are flammable liquids, solids or gases such as paint solvents, etc.

DO NOT allow children to operate the drill.

DO NOT operate the drill if any parts are missing as this may cause failure or possible personal injury.

DO NOT carry the drill with your finger on the power switch. Keep chuck direction switch in the locked position.

DO NOT use the drill for a task it is not designed to perform.

DO NOT operate the drill when you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT get the drill or battery charger wet or use in damp or wet locations.

Keep drill and charger in the case and store in a safe, dry, childproof area where the temperature will not exceed 104°F (40° C).

1.2. BATTERY SAFETY INSTRUCTIONS

WARNING! The battery pack contains nickel-cadmium which is dangerous. It must therefore be handled with care

to avoid damage, fire, corrosion or personal injury.

Charge battery pack prior to first use. The battery pack will have been shipped in a low charge state.

Use only the charger provided to charge the battery pack.

DO NOT charge the battery pack when room temperature is below 50°F (10°C) or above 95°F (35°C).

DO NOT attempt recharging the pack by means of an engine generator or a DC power source.

DO NOT short-circuit the battery pack by touching both terminals with a metal object, or your fingers etc.

DO NOT store the battery pack (or drill) in locations where the temperature may exceed 104°F (40°C) - such as outside sheds, above

heaters, or metal buildings in summer.

WARNING! Dispose of spent battery pack in line with local authority guidelines as it contains nickel-cadmium.

DANGER! DO NOT attempt to disassemble the battery pack. For safety and environmental reasons DO NOT discard in domestic

waste or by burning. ONLY discard or recycle according to local authority regulations.

WARNING!

DO NOT allow a leaking battery to contact your person.

If you come into contact with battery liquid take the following immediate action:

a) Skin contact: Wash immediately with soap and water, then wash flesh in either lemon juice or vinegar.

b) Eye contact: Wash with a strong solution of boric acid and seek immediate medical attention.

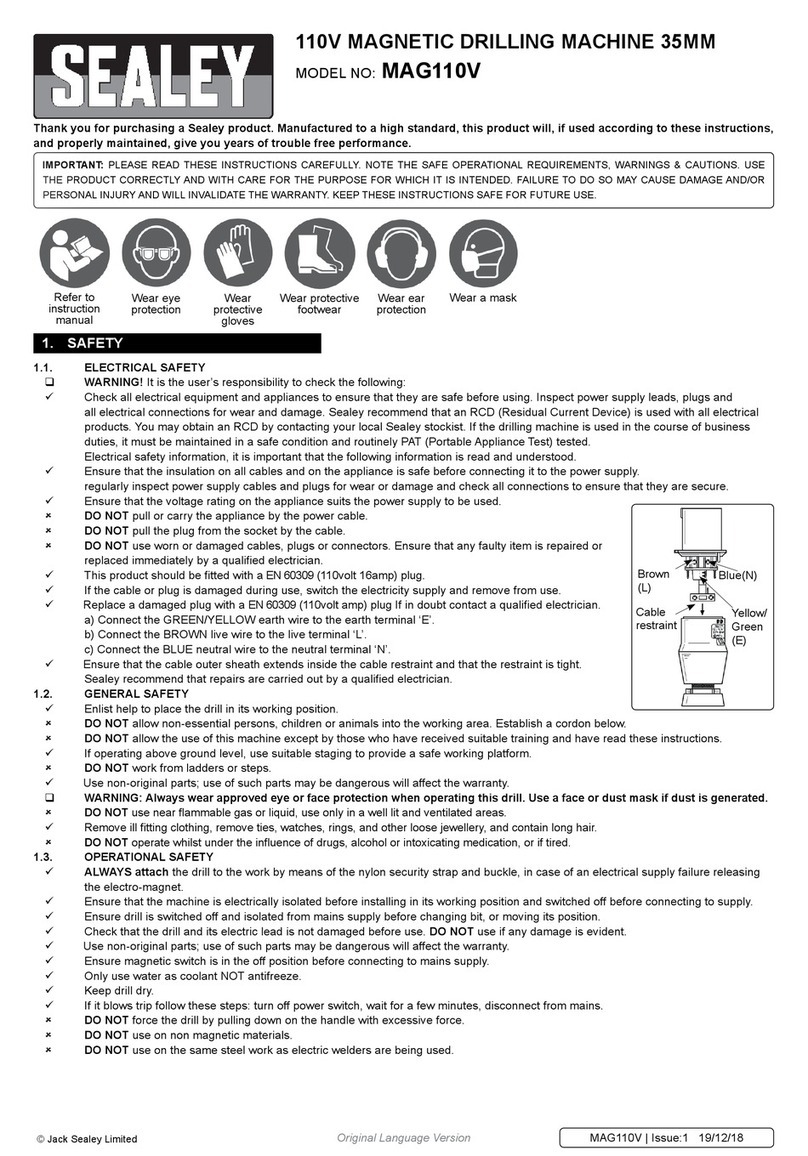

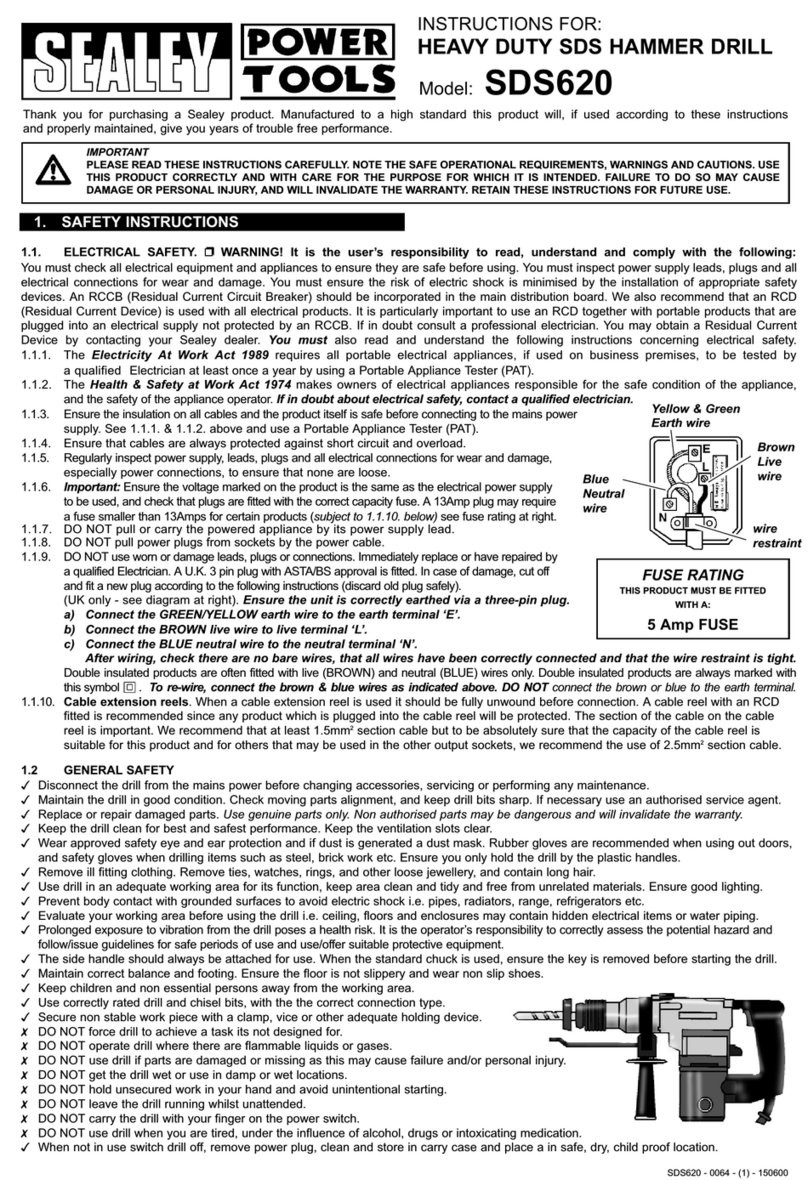

1.3. MAINS POWER ELECTRICAL SAFETY (In relation to the battery charger)

WARNING! It is the owner’s responsibility to check the following:

You must check all electrical equipment and appliances to ensure they are safe before using. You must inspect power supply leads,

plugs and all electrical connections for wear and damage. You must ensure that the risk of electric shock is minimised by the

installation of appropriate safety devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main distribution

board. We recommend that an RCD (Residual Current Device) is used with all electrical products. It is particularly important to use an

RCD with portable products that are plugged into a supply not protected by an RCCB. If in doubt consult a qualified electrician. You

may obtain an RCD by contacting your dealer. You must also read and understand the following instructions concerning electrical

safety.

1.3.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by a qualified

person, using a Portable Appliance Tester (PAT), at least once a year.

1.3.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of the appliance and

the safety of the appliance operator. If in any doubt about electrical safety, contact a qualified electrician.

1.3.3. Ensure that the insulation on all cables and the product itself is safe before connecting to the mains power supply. See 1.3.1. above

and use a Portable Appliance Tester (PAT).

1.3.4. Ensure that cables are always protected against short circuit and overload.

1.3.5. Regularly inspect power supply leads, plugs and sockets for wear, damage or loose connections.

1.3.6. Check that the voltage marked on the product is the same as the power supply to be used and check that the plug is fitted with the

correct capacity fuse.

Original Language Version CP3014VHK, CP3018VHK Issue: 5 - 11/01/12