fig. 3

fig. 4

4. MAINTENANCE

5. DECLARATION OF CONFORMITY

4.1. Cleaning

Keep the drill ventilation slots clean and free from obstructions. If available, blow compressed air into the vents to clear

any accumulated dust (safety goggles must be warn when undertaking this process).

Keep the outer case of the drill clean and free from grease. DO NOT wash with water or use solvents or abrasives.

Declaration of Conformity We, the sole importer into the UK, declare that the products listed here are in conformity with the following standards and directives.

The construction files for these products are held by the Manufacturer and may be inspected

on request by contacting Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Power Tools.

Cordless Hammer Drill

& Battery Charger

Models: CP2440VHK & CB2405BC

73/23/EEC LV Directive

89/336/EEC EMC Directive

98/37/EC Machinery Directive

93/68/EEC CE Marking Directive

Signed by Mark Sweetman 20th January 2005

01284 757500 sales@sealey.co.uk www.sealey.co.uk01284 703534

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No responsibility is accepted for the incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions, call us on 01284 757525 and leave your full name and address, including post code.

e-mail Web

CP2440VHK - 1 - 210105

3.2. DRILLING INSTRUCTIONS (Ensure that you read, understand and comply with all the Section 1 safety instructions)

p

p

WARNING! Always wear approved safety glasses when drilling.

3.2.1. Preparation

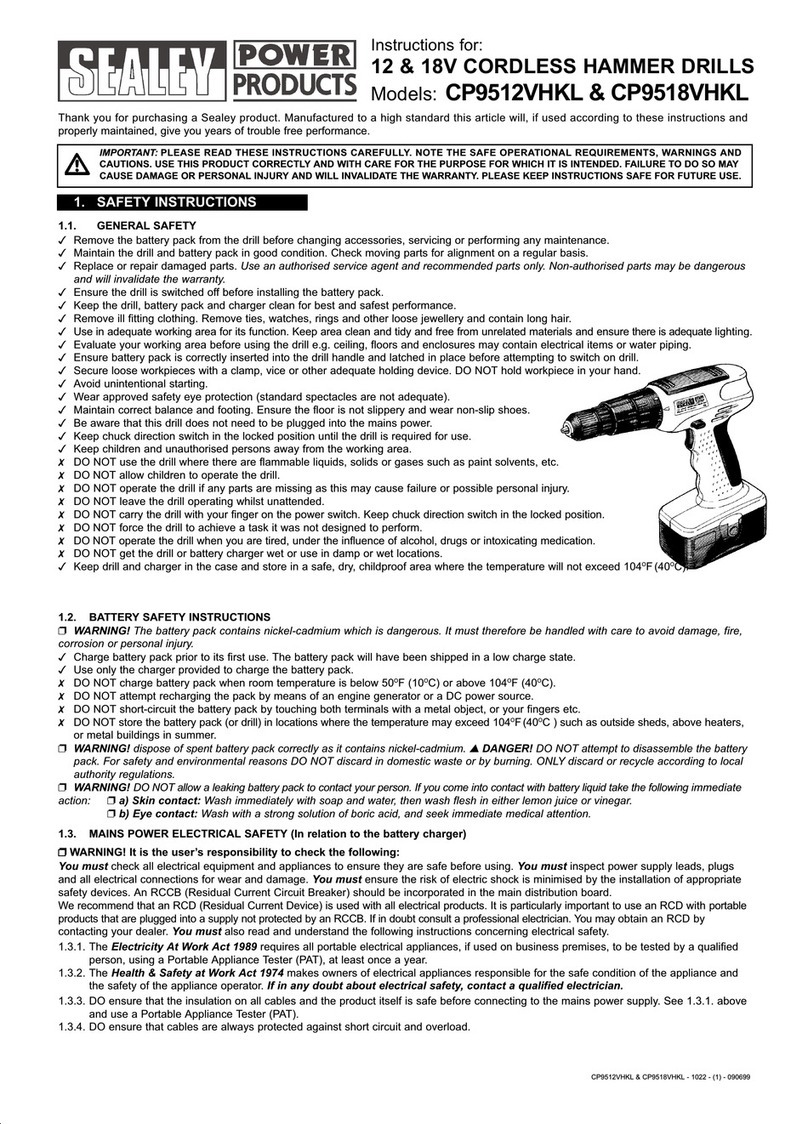

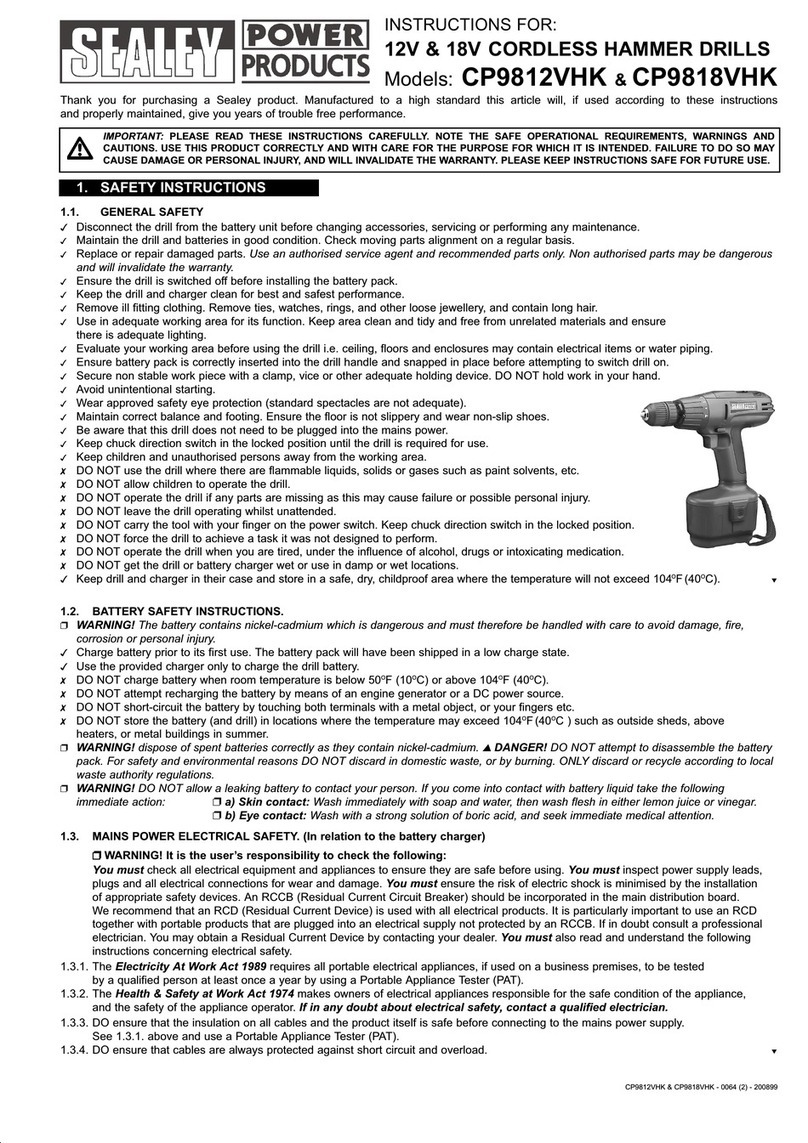

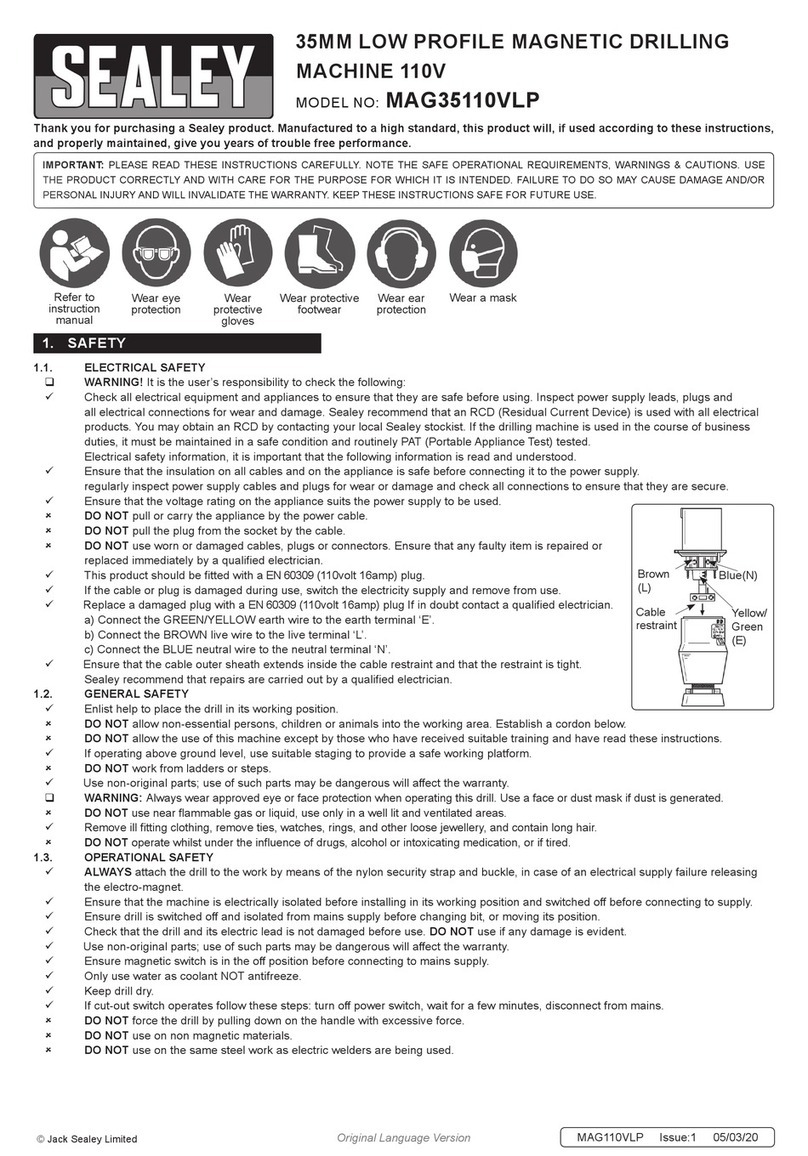

1. Open the chuck by holding the rear collar (fig. 3.2) and turn the front chuck collar (fig. 3.1).

2. Insert the required bit fully into the chuck and tighten.

3. Check the drill to ensure the direction switch (fig. 3.6) is in the mid (locked) position.

4. Fit the battery pack to the drill handle.

5. Press the direction switch (fig. 3.6) in from the right, as you view drill from rear (as held), for clockwise rotation,

and press in from the left for anti-clockwise rotation (withdrawing drill bits, undoing screws).

NOTE: Do not attempt to change direction of rotation while the drill is running.

3.2.2. Drill Speed

1. Speed of the drill is controlled by the electronic variable speed switch (fig. 3.5). Press the switch gently for a slow speed and progressively

increase the pressure on the switch to produce correspondingly higher speeds.

2. The maximum revolutions may also be adjusted by changing the two speed switch (fig. 3.7).

NOTE: DO NOT change the speed range whilst the drill is running.

3.2.3. Torque setting (fig. 3.4)

Torque is the amount of turning force applied by the drill. Torque setting 1 on the dial (fig. 3.4) is the lowest and will apply the

least effort - to the final turns of a screw, for example. The torque becomes progressively greater with increased setting numbers,

up to 8.

The drill symbol position givesmaximum torquewith no clutch effect. The combination of variable speed and variable torque gives

maximum drilling/screw driving efficiency.

The lower torque settings are suitable for driving small screws and drilling with fine drill bits, to prevent shearing of the screws/bits.

Screws/bits of larger diameter permit higher torque settings to be used.

3.2.4. As a screw or bolt driver

1. Lock the appropriate tool bit in the chuck. Select the shortest length bit possible to ensure greatest control.

2. A small pilot hole may be required to ease the path of the screw, especially in hard woods.

3. Set a low torque to begin with, gradually increasing the torque if necessary.

4. To remove screws, press direction switch in from the left for reverse (anti-clockwise).

5. When finished, remove the bit from the chuck, clean drill and bit and store in the carry case.

3.2.5. Hammer action (fig. 3.3)

pWARNING! DO NOT use the hammer action with metal/wood drill bits as these may shatter. Use only with masonry bits.

The hammer action, with a masonry drill bit, is used to assist drilling into concrete, stone and masonry. To use the hammer function rotate

the control ring (fig. 3.3) to select the hammer symbol on the control ring. To disengage the hammer function turn the control back

in the direction of the drill symbol on the control ring. Note: DO NOT shift to hammer when the drill is running as this

may damage the machine.

3.2.6. Drilling

p

p

WARNING! Ensure that you read and understand Section 1 safety instructions before using the drill.

1. If the workpiece to be drilled is loose it should be secured in a vice or with clamps to keep it from turning as the drill bit rotates.

2. When drilling metals, use a light oil on the drill bit to keep it from overheating. Oil will prolong bit life and improve the drilling action.

3. For hard, smooth surfaces use a centre punch to mark desired hole location. This will prevent bit from slipping as you start to drill.

4. A pilot hole may be necessary to assist the final size drill through the workpiece.

Lock a pilot drill in the chuck. Follow steps 5 to 8 below and drill a pilot hole at the centre punch mark where the final hole is to be drilled.

Insert the final sized bit. Hold the drill firmly, place the tip of the bit in the pilot hole and depress the trigger.

5. Move the drill bit into the workpiece applying only enough pressure to keep the bit cutting.

DO NOT force the drill or apply side pressure to elongate the hole.

6. Regularly withdraw the drill bit from the hole in order to clear cuttings.

7. Ease the pressure of drilling when the bit is about to break through the far side of the workpiece.

p

p

WARNING! Be prepared for drill bit binding or break through. When these situations occur the bit has a tendency to grab and the drill

will kick, which could cause loss of control. If not prepared, this loss of control may result in damage and/or personal injury.

8. If the bit jams in the workpiece or if the drill stalls, release the trigger switch immediately. Place the drill in reverse to assist release of the bit.

9. After a long period of continuous operation, allow the drill to run with no load and at maximum speed to cool the motor.

p

p

WARNING! Drill bits can become very hot during use. Allow to cool or hold with a cloth for removal.

When finished, remove bit from chuck, clean drill, clean, and, if necessary, re-sharpen bit and store in a safe, dry, childproof area.

3.2.7. Additional features

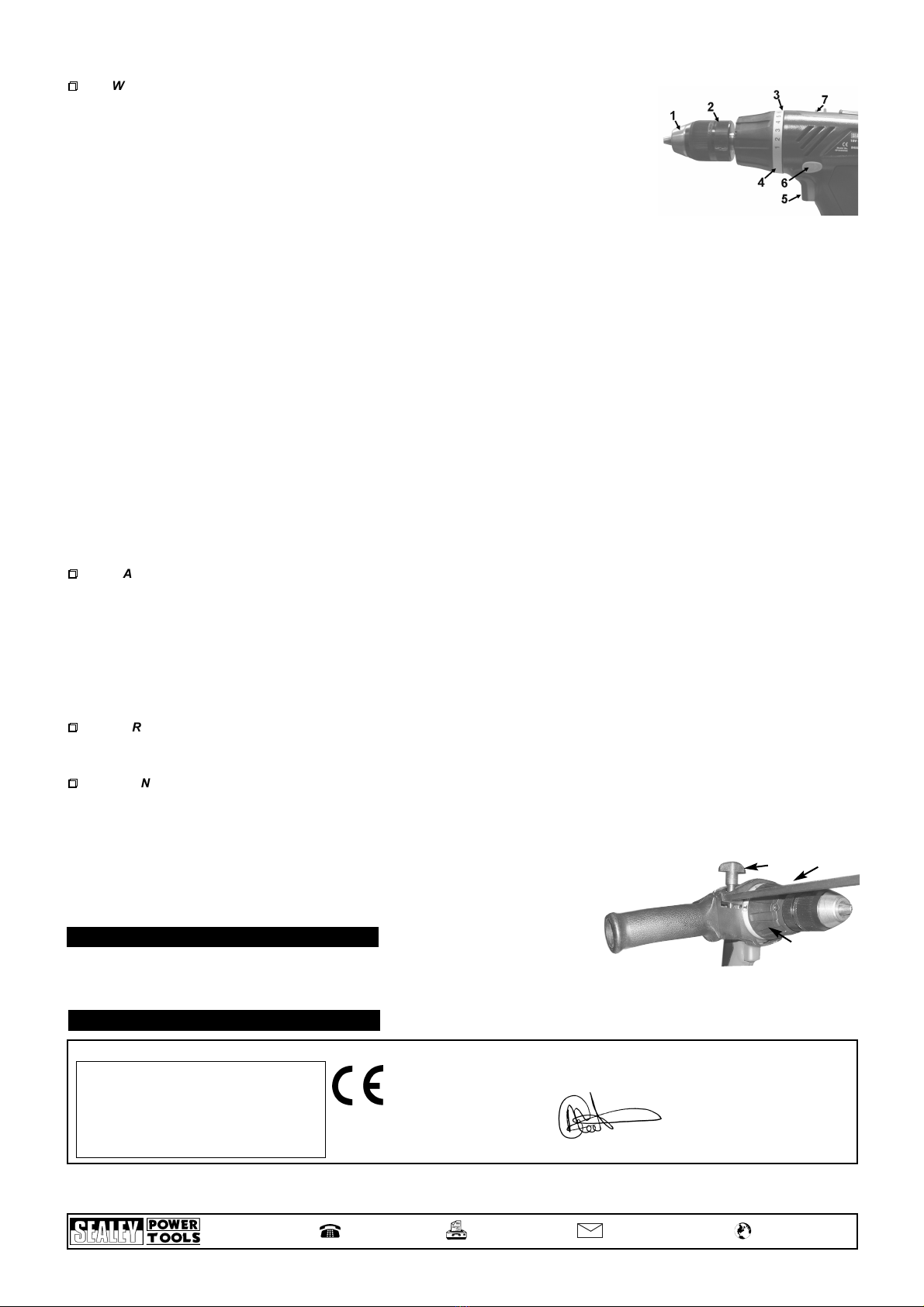

The front handle (fig.1.10) helps to control the drill in use. Loosen the clamp screw (fig.4.1) and slide handle over front of drill

housing ensuring the recess in the clamp ring fits over the underside of the drill (fig.4.2). When correctly located the clamp will sit

immediately behind the variable torque control ring. The clamp can be fitted to suit left or right handed positions. Firmly tighten the

clamp screw to secure the clamp in position.

The depth gauge (fig.4.3) gives accurate and repeatable control over drilling depth. In order to fit, and

subsequently to adjust, the gauge rod it is necessary to loosen the front handle clamp

screw (fig.4.1). When the rod position is correct,

firmly tighten the clamp screw.

1

2

3