Instructions for:

VARIABLE SPEED PILLAR DRILLS

Models: GDM150B/VS & GDM200F/VS

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

GDM150B/VS & GDM200F/VS - 1 - 110402

1.1. ELECTRICAL SAFETY

p WARNING! It is the responsibility of the owner and the operator to read, understand and comply with the following:

You must check all electrical products, before use, to ensure that they are safe. You must inspect power cables, plugs, sockets and any other

connectors for wear or damage. You must ensure that the risk of electric shock is minimised by the installation of appropriate safety devices.

A Residual Current Circuit Breaker (RCCB) should be incorporated in the main distribution board. We also recommend that a Residual Current

Device (RCD) is used. It is particularly important to use an RCD with portable products that are plugged into a supply which is not protected

by an RCCB. If in any doubt consult a qualified electrician. You may obtain a Residual Current Device by contacting your Sealey dealer.

You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity at Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by a qualified

electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances

and the safety of the appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply. See 1.1.1. and 1.1.2.

and use a Portable Appliance Tester.

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply cables and plugs for wear or damage and check all

connections to ensure that none is loose.

1.1.6. Important: Ensure that the voltage marked on the appliance matches the power supply

to be used and that the plug is fitted with the correct fuse - see fuse rating at right.

1.1.7. DO NOT pull or carry the appliance by the power cable.

1.1.8. DO NOT pull the plug from the socket by the cable.

1.1.9. DO NOT use worn or damaged cables, plugs or connectors. Immediately have any faulty

item repaired or replaced by a qualified electrician. When an ASTA/BS approved UK

3 pin plug is damaged, cut the cable just above the plug and dispose of the plug safely.

Fit a new plug according to the following instructions (UK only).

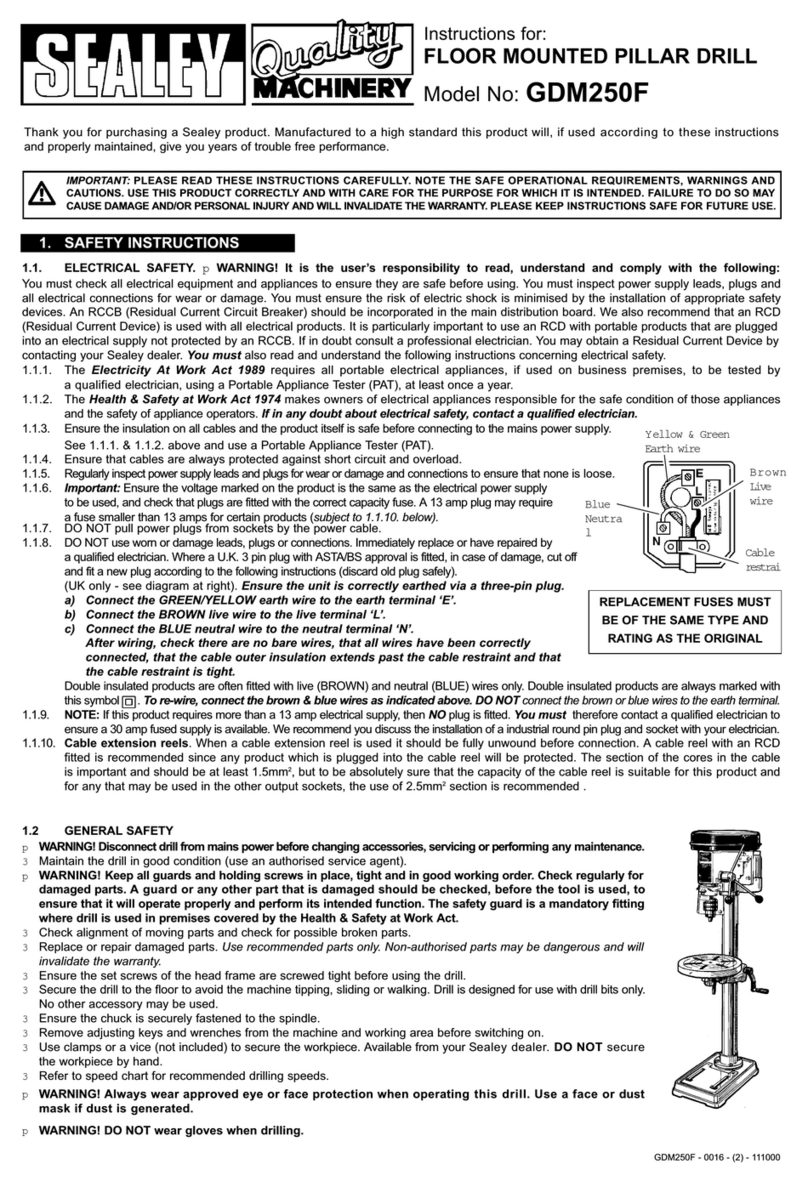

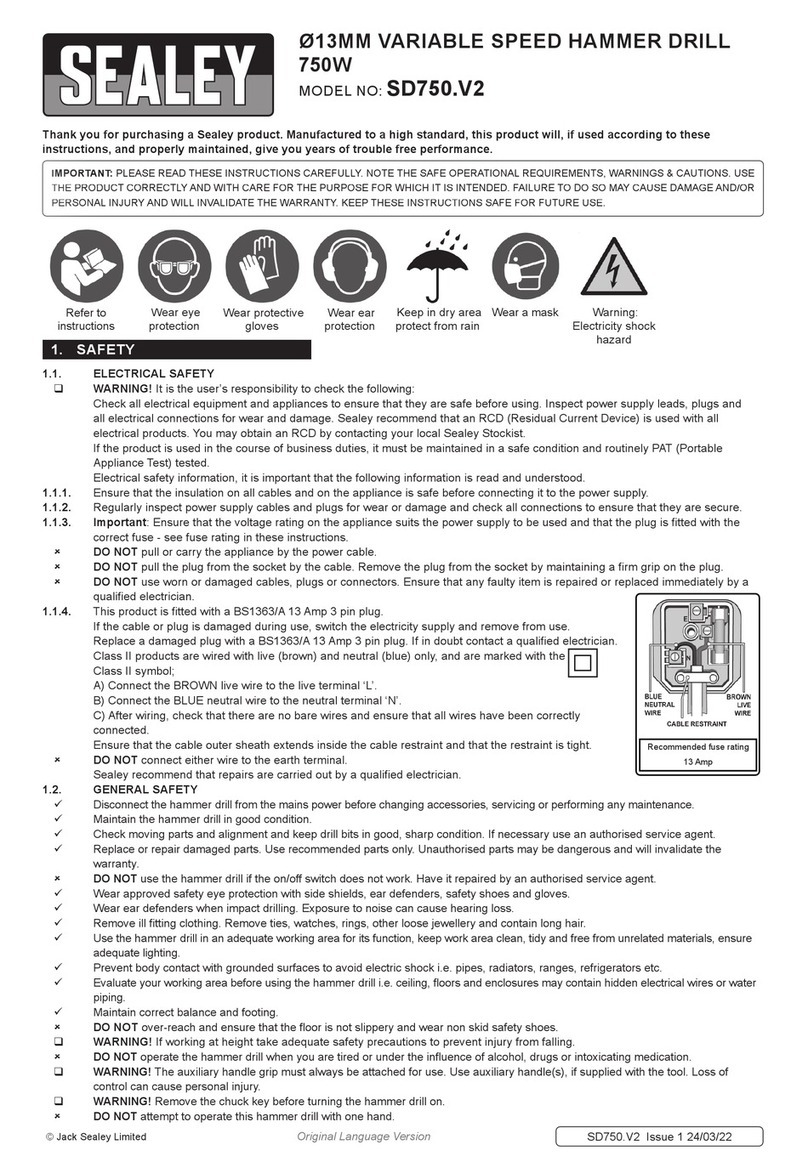

a) Connect the GREEN/YELLOW earth wire to the earth terminal E.

b) Connect the BROWN live wire to the live terminal L.

c) Connect the BLUE neutral wire to the neutral terminal N.

d) After wiring, check that there are no bare wires, that all wires have been correctly connected, that the cable outer insulation

extends beyond the cable restraint and that the restraint is tight.

Double insulated products, which are always marked with this symbol , are fitted with live (brown) and neutral (blue) wires only.

To rewire, connect the wires as indicated above - DO NOT connect either wire to the earth terminal.

1.1.10. Products which require more than 13 amps are supplied without a plug. In this case you must contact a qualified electrician to ensure that a

suitably rated supply is available. We recommend that you discuss the installation of an industrial round pin plug and socket with your electrician.

1.1.11. If an extension reel is used it should be fully unwound before connection. A reel with an RCD fitted is preferred since any appliance

plugged into it will be protected. The cable core section is important and should be at least 1.5mm2, but to be absolutely sure that the

capacity of the reel is suitable for this product and for others which may be used in the other output sockets, we recommend the use of

2.5mm2section cable.

1. SAFETY INSTRUCTIONS

FUSE RATING 13 AMP

Blue

Neutral

Wire

Yellow & Green

Earth Wire

Cable

Restraint

Brown

Live

Wire

1.2. GENERAL SAFETY

pWARNING! Disconnect drill from mains power before changing accessories, servicing or performing any maintenance.

3Maintain the drill in good condition (use an authorised service agent).

pWARNING! Keep all guards and holding screws in place, tight and in good working order. Check regularly for

damaged parts. A guard, or any other part, that is damaged must be repaired or replaced before the tool

is next used, to ensure that it will operate properly and perform its intended function. The safety guard is a

mandatory fitting where the drill is used on premises covered by the Health & Safety at Work Act.

3Check alignment of moving parts and check for possible broken parts.

3Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will

invalidate the warranty.

3Ensure that the head frame set screws are tight before using the drill.

3Secure the drill to a supporting structure to avoid the machine tipping, sliding or walking. Drill is designed for use

with drill bits and mortice attachments only. No other accessory may be used.

3Ensure the chuck is securely fastened to the spindle.

3Remove chuck keys and wrenches from the machine and work area before switching on.

3Use clamps or a vice (not included but available from your Sealey dealer). DONOT secure the workpiece by hand.

3Refer to speed chart for recommended drilling speeds.

pWARNING! Always wear approved eye or face protection when operating this drill. Use a face or dust

mask if dust is generated.

pWARNING! DO NOT wear gloves when drilling.