INSTRUCTIONS FOR:

GAS WELDING/CUTTING KITS

MODEL NOS: SGA2 & SGA6

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained, give

you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

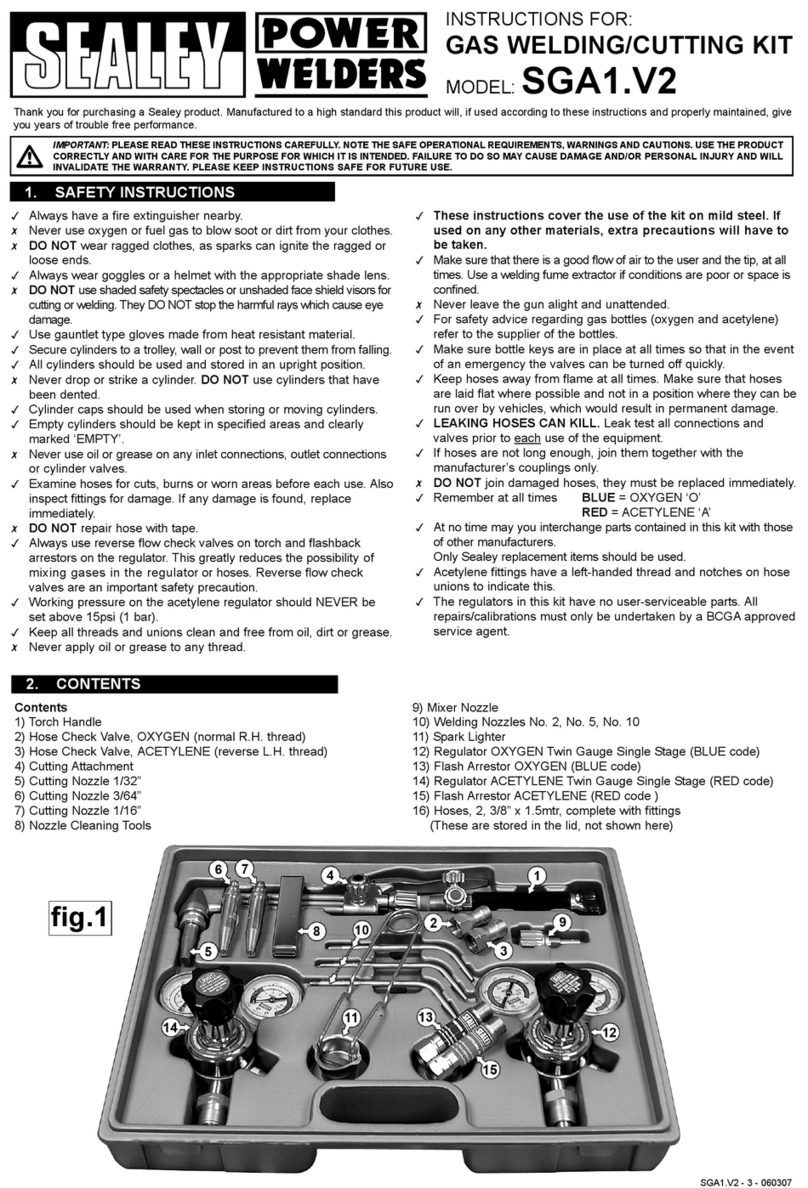

Contents: SGA6

1) Torch Handle

2) Welding Nozzles No. 2, No. 5, No. 10

3) Mixer Nozzle

4) Cutting Attachment

5) Cutting Nozzle 1/32”

6) Cutting Nozzle 3/64”

7) Cutting Nozzle 1/16”

8) Nozzle Cleaning Tools

Contents: SGA2

1) Torch Handle

2) Welding Nozzles No. 2, No. 5, No. 10

3) Mixer Nozzle

Basic Nozzle Cleaning Tool (Not shown)

!Always have a fire extinguisher nearby.

"Never use oxygen or fuel gas to blow soot or dirt from your clothes.

"DO NOT wear ragged clothes, as sparks can ignite the ragged or

loose ends.

!Always wear goggles or a helmet with the appropriate shade lens.

"DO NOT use shaded safety spectacles or unshaded face shield

visors for cutting or welding. They DO NOT stop the harmful rays

which cause eye damage.

!Use gauntlet type gloves made from heat resistant material.

!Secure cylinders to a trolley, wall or post to prevent them from falling.

!All cylinders should be used and stored in an upright position.

"Never drop or strike a cylinder. DO NOT use cylinders that have

been dented.

!Cylinder caps should be used when storing or moving cylinders.

!Empty cylinders should be kept in specified areas and clearly

marked ‘EMPTY’.

"Never use oil or grease on any inlet connections, outlet connections

or cylinder valves.

!Examine hoses for cuts, burns or worn areas before each use.

Also inspect fittings for damage. If any damage is found, replace

immediately.

"DO NOT repair hose with tape.

!Always use reverse flow check valves on torch and flashback

arrestors on the regulator. This greatly reduces the possibility of

mixing gases in the regulator or hoses. Reverse flow check

valves are an important safety precaution.

!Working pressure on an acetylene regulator should NEVER be

set above 15psi (1 bar).

!Keep all threads and unions clean and free from oil, dirt or grease.

"Never apply oil or grease to any thread.

!These instructions cover the use of the kits on mild steel. If

used on any other materials, extra precautions will have to

be taken.

!Make sure that there is a good flow of air to the user and the tip, at all

times. Use a welding fume extractor if conditions are poor or space is

confined.

"Never leave the torch alight and unattended.

!For safety advice regarding gas bottles (oxygen and acetylene)

refer to the supplier of the bottles.

!Make sure bottle keys are in place at all times so that in the event

of an emergency the valves can be turned off quickly.

!Keep hoses away from flame at all times. Make sure that hoses

are laid flat where possible and not in a position where they can be

run over by vehicles, which would result in permanent damage.

!LEAKING HOSES CAN KILL. Leak test all connections and

valves prior to each use of the equipment.

!If hoses are not long enough, join them together with the

manufacturer’s couplings only.

"DO NOT join damaged hoses, they must be replaced immediately.

!Remember at all times BLUE = OXYGEN ‘O’

RED = ACETYLENE ‘A’

!At no time may you interchange parts contained in this kit with those

of other manufacturers.

Only Sealey replacement items should be used.

!Acetylene fittings have a left-handed thread and notches on hose

unions to indicate this.

2. CONTENTS

fig.1

01284 757500

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

www.sealey.co.uk

Web

email

SGA2 & SGA6 - 4 - 09/02/06

5.3 SETTING THE GAS REGULATOR PRESSURES Close the regulators by turning the adjusting screws anti-clockwise to relieve the

pressure on the diaphragm before opening the cylinder valves. Slowly open the cylinder valve on the oxygen and acetylene bottles in

turn. As you do so the high pressure gauge (left hand) on each regulator will register the pressure in the cylinder to which it is attached.

5.3.1 Slowly open each regulator in turn by turning the adjusting knob clockwise. As you do so the outlet pressure gauge (right hand) on

each regulator will register the outlet pressure of gas being fed to the torch. Adjust the pressure according to the size of nozzle in

use and the thickness of the material to be cut . Refer to the chart in section 7.1.

#WARNING! Never set acetylene regulator at a delivery pressure above 15psi (1 bar).

5.3.2 After adjusting the regulators to the desired operating pressures check connections for leaks using an approved leak detection solution.

Check for leaks at all connections. If a leak is found, tighten fitting more securely. If leak persists, discontinue use and call your supplier.

5.3.3 Briefly open and close the acetylene valve on the torch handle to check that the gas is flowing.

5.3.4 Ensure that the oxygen control valve on the cutting attachment is closed.

5.3.5 Fully open the oxygen control valve on the torch handle.

5.3.6 Briefly open and close the oxygen control valve on the cutting attachment to check that the gas is flowing.

5.3.7 Briefly operate the oxygen control lever on the cutting attachment to check that the gas is flowing from the centre of the cutting nozzle.

#WARNING! Always use welding gloves and suitable eye protection when welding or cutting. Contact your local Sealey dealer for a

full range of protective equipment.

5.4 LIGHTING THE TORCH Ensure that the gas hoses will not be in the way of the torch when ignited. Ensure that the torch is facing

away from you before lighting.

5.4.1 Holding the torch in one hand and the striker in the other open the acetylene valve on the torch handle a 1/4 turn (the valve knob is

colour coded red). Operate the striker close to the tip to light the acetylene.

5.4.2 The cutting tip has six separate holes in it arranged radially and each of these holes will have a small flame coming from it. Develop

the correct flame at each hole by alternately increasing the flow of acetylene and then oxygen until a neutral flame is achieved at each

hole having a white cone about an 1/8” long.

5.5 USING THE OXYGEN CONTROL LEVER Use the pre-heat flame to heat the metal to be cut to a cherry red colour. When the metal

reaches this stage press the oxygen control lever to initiate the cutting process. This feeds additional oxygen through a central hole in

the cutting tip. No flame is produced from this hole but the pure oxygen reacts chemically with the hot metal causing it to oxidise i.e. burn away.

5.6 SHUTTING DOWN AND LEAVING SAFE Turn off the acetylene valve on the torch first and then turn off the oxygen valve a few

moments later. Note: Turning the gases off in the wrong order can cause damage to the torch.

5.6.2 Close both cylinder valves.

5.6.3 Drain gas from oxygen regulator by opening the oxygen valve on the torch handle. Similarly drain gas from the acetylene regulator.

5.6.4 Release the adjusting knobs on the regulators. This is done by turning them anti-clockwise.

6. MAINTENANCE

6.1 Annual maintenance should be carried out by a person who has sufficient practical experience of oxyacetylene gas equipment and a

detailed theoretical knowledge of the functioning of the equipment, the properties of gases used and potential defects and hazards

which may occur and their importance to the integrity and safety of the equipment.

6.2 The chart shown below relates to Blowpipes. A similar maintenance schedule should be carried out in relation to Regulators,

Flashback Arrestors and Hose assenblies as laid down in the Code of Practice CP7 of the British Compressed Gases Association.

EQUIPMENT MAINTENANCE

Each time equipment is used Annual Replacement/ Replacement/

(By the operator) Refurbishment Refurbisment

Intervals Guideline

BLOWPIPES Visual examination of the nozzle Test valve functions. Blank Determined by local Replace with a new,

and inlet seatings for damage. exits and leak test for internal operating conditions. repaired, or service

Leak test all joints at working malfunctions. exchange unit.

pressure.

For Jack Sealey Ltd. Sole UK importer of Sealey Power Welders.

Declaration of Conformity We, the sole UK importer, declare that the products listed below are in conformity with the following standards and directives.

The construction file for these products are held by the Manufacturer and may

be inspected, by a national authority, upon request to Jack Sealey Ltd.

GAS WELDING/CUTTING KITs

Model: SGA2 & SGA6

BS EN ISO 5172:1997 Manual blowpipes for welding, cutting and heating Signed by Tim Thompson 9th February 2006

8. DECLARATION OF CONFORMITY

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our catalogue and latest promotions call us on 01284 757525 and leave your full name, address and postcode.

7.1.CUTTING CAPACITIES

Mild Nozzle Operating Pressure (bar - lbf/in²) Gas Consumption (ltr/m - ft³/h)

Steel Size Oxygen Acetylene O2- Cutting O2- Heating Acetylene

6mm / 1/4” 1/32” 1.4 - 20 0.30 - 4 14.15 - 30 8.5 - 18 8.0 - 17

13mm / 1/2” 3/64” 2.1 - 30 0.35 - 5 30.70 - 65 10.4 - 22 9.4 - 20

25mm / 1” 1/16” 2.8 - 40 0.40 - 6 67.50 - 143 13.2 - 28 11.8 - 25

50mm / 2” 1/16” 3.1 - 45 0.40 - 6 78.30 - 166 13.2 - 28 11.8 - 25

75mm / 3” 1/16” 3.5 - 50 0.40 - 6 88.70 - 188 13.2 - 28 11.8 - 25

7.2.WELDING CAPACITIES

Mild Nozzle Operating Pressure (bar - lbf/in²) Gas Consumption (ltr/m - ft³/h)

Steel Size Oxygen Acetylene O2- Welding O2- Heating Acetylene

1.2mm / 18SWG LW02 0.14 - 2 0.14 - 2 11.8 - 25 4.2 - 9 3.8 - 8

2.6mm / 12SWG LW05 0.28 - 4 0.21 - 3 23.5 - 50 4.2 - 9 3.8 - 8

4mm / 8SWG LW10 0.35 - 5 0.28 - 4 56.6 - 120 4.2 - 9 3.8 - 8

7. TECHNICAL INFORMATION

SGA2 & SGA6 - 4 - 09/02/06