2

Content / Contenido / Содержание / Зміст / Мазмұны /

English

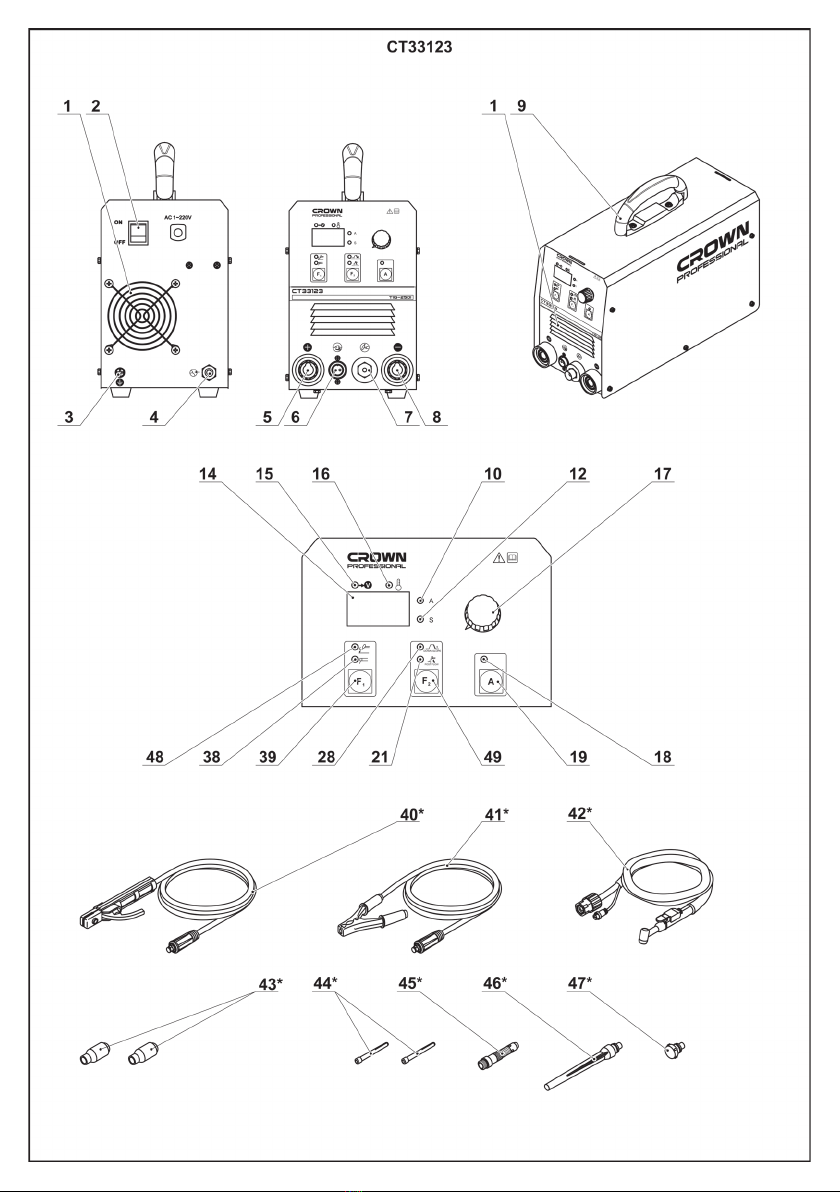

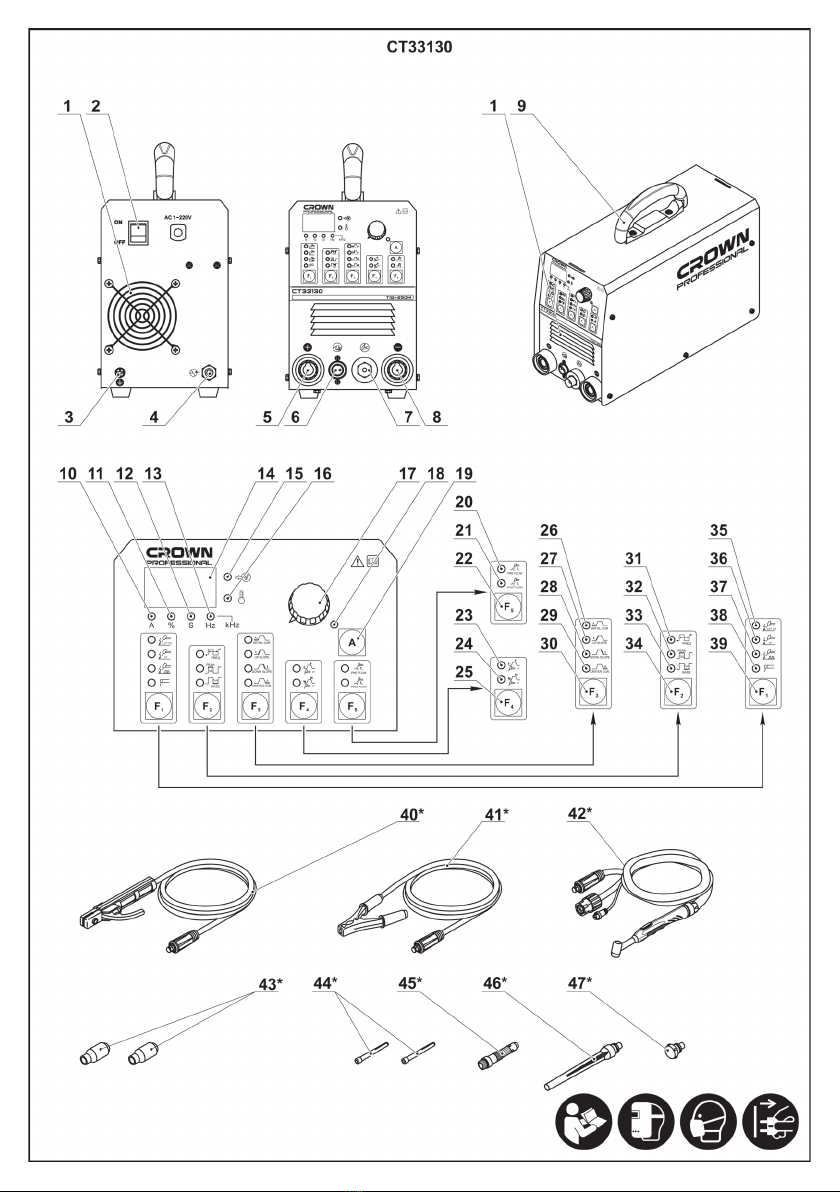

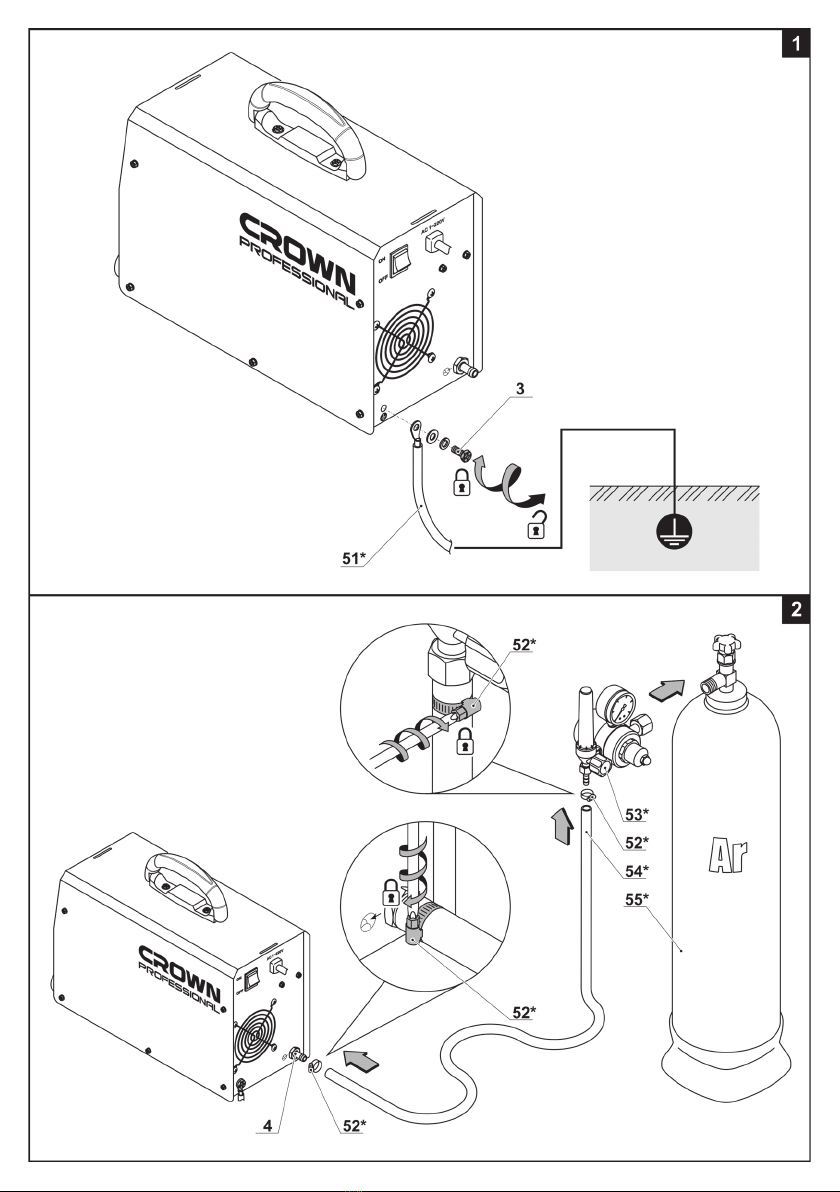

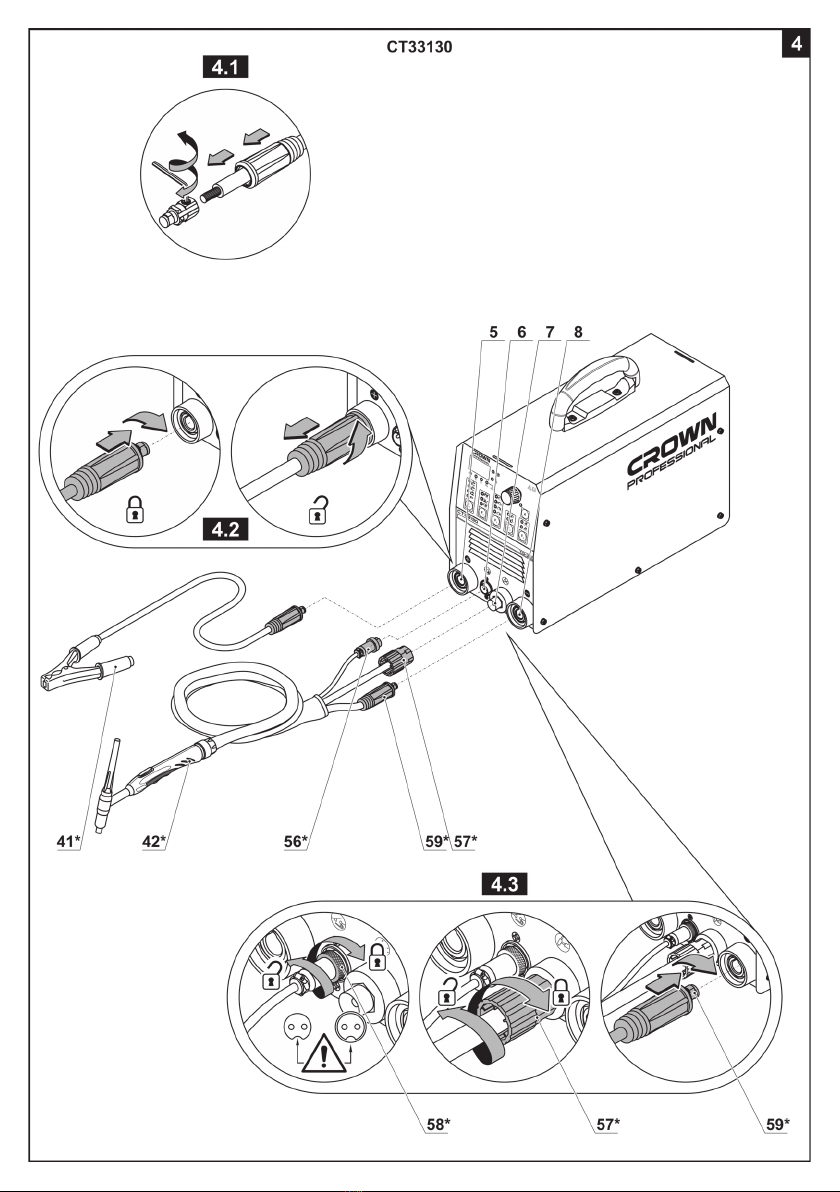

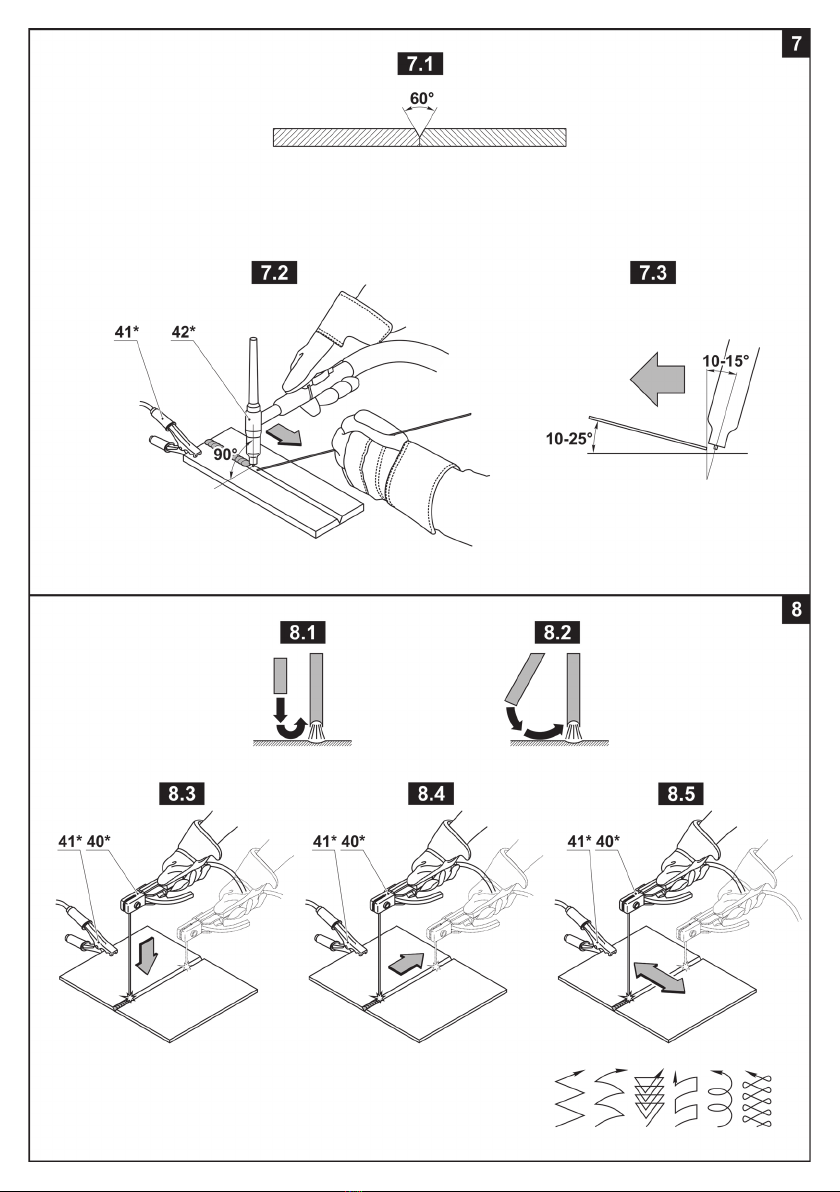

Explanatory drawings ������������������������������������������������������������������������������������������������������������ pages

General safety rules, instructions manual ����������������������������������������������������������������������������� pages

3 - 10

11 - 19

Español

Dibujos explicativos ������������������������������������������������������������������������������������������������������������ páginas

Recomendaciones generales de seguridad, manual de instrucciones ������������������������������ páginas

3 - 10

20 - 29

Русский

Пояснительные рисунки ������������������������������������������������������������������������������������������������ страницы

Общие указания по ТБ, инструкция по эксплуатации ������������������������������������������������� страницы

3 - 10

30 - 39

Украïнська

Пояснювальні малюнки ��������������������������������������������������������������������������������������������������� сторінки

Загальні вказівки по ТБ, iнструкція з експлуатації ��������������������������������������������������������� сторінки

3 - 10

40 - 49

Қазақ тілі

Түсіндіргіш әлеміштер �������������������������������������������������������������������������������������������������������� беттер

Жалпы қауіпсіздік жөніндегі ұсыныстар, пайдалану нұсқаулығы ���������������������������������������� беттер

3 - 10

50 - 59

����������������������������������������������������������������������������������������������������������������������������

����������������������������������������������������������������������������������������������������

3 - 10

60 - 68

�������������������������������������������������������������������������������������������������������������������������

��������������������������������������������������������������������������������������������

3 - 10

69 - 76