Sealy SGA3/FBA User manual

OXYGEN/FUEL FLASHBACK

MODEL NO’S: SGA3/FBA, SGA4/FBA

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

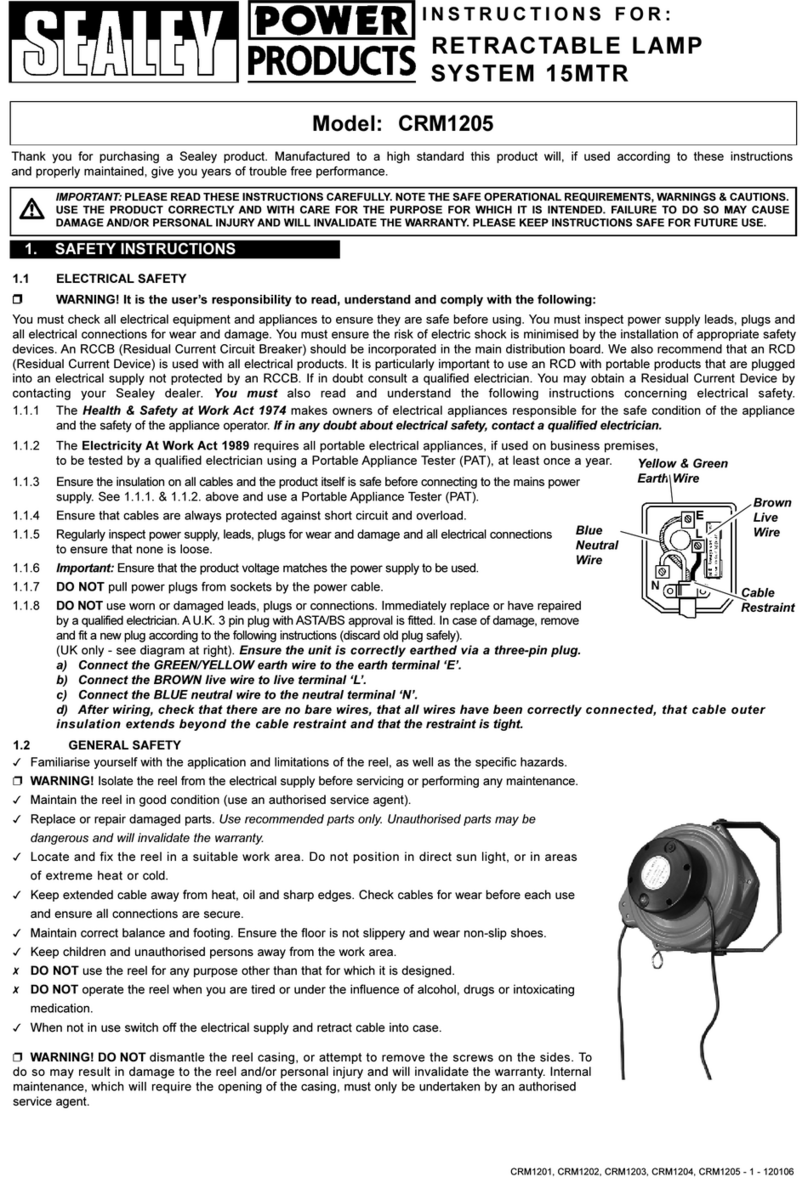

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURYAND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Refer to

instruction

manual

SGA3/FBA, SGA4/FBA Issue 1 16/12/2022

Original Language Version

© Jack Sealey Limited

Wear eye

protection

1. SAFETY

1.1. SPECIFIC FLASHBACK ARRESTOR SAFETY WARNINGS

9 Theinformationontheashbackarrestorsuchasdescriptionofgas,maximumoperatingpressureanddirectionofowsignhas

tobefollowed.

9 Morethanonecomponentshouldn’tbeconnectedtotheashbackarrestor.

9 Nomarking(e.g.itemnumber,dateofrstoperationetc.)byscratchingorpunchingisadvised.Underthesecircumstances,

9 Flashbackarrestormaygetdamagedandleakagemayoccur.

9 Flashbackarrestorsshouldbeusedaccordingtotheinformationmarkedonthem.

9 Theseproductsaremanufacturedbylatesttechnologyregardingtospecifytechnicalrules,presentstandardsandinstructions.

9 Usermustfollowtherecommendationsinthismanual.

9 Stathatuseweldingequipmentandtheircomponentsshouldhaveknowledgeabouttheseprocessesorbetrainedbyregisteredby

institute/staaccordingtocurrentregulationsinplace.

9 Alwayshaveareextinguishernearby.

9 Itisimportanttoreadtheinformationontheashbackarrestorwhichgivesadescriptionofgas,maximumoperatingpressureand

directionofowwhichneedstobenotedandobserved.

9 Morethanonecomponentshouldn’tbeconnectedtotheashbackarrestor.

1.2. SITUATIONS THAT MAY CAUSE FLASHBACK

9 Whencuttingtorchisdamagedorusedincorrectly.

9 Whenhighpressurizedoxygengasmixedinthelowpressurizedammablegasttingasaresultofwrongadjustmentofoperating

pressures.

9 Whencomponentsconnectedwhicharenotsuitableforeachother.

9 IftheOxygencylinderrunoutofgas;ammablegasowsinsidetheoxygencylinderreverselythroughregulator.

9 Whenuntutoredandinexperiencedusersusetheproducts.Wheninstructionsarenotfollowed.

9 Whencomponentsareconnectedwiththewrongtools.

9 Usageofgasesorpressuresdierentthanoneswhicharedenedonthismanualandontheproduct.

9 Whenproductisusedattemperaturesunder-20°Candover+60°C.

1.3. Keepawayfromameatalltimes.Makesurethathosesarelaidatwherepossibleandnotinapositionwheretheycanbe

runoverbyvehicles,whichwouldresultinpermanentdamage.

9 Emptycylindersshouldbekeptinspeciedareasandclearlymarked‘EMPTY’.

8 Neveruseoilorgreaseonanyinletconnections,outletconnectionsorcylindervalves.

9 Examinehosesforcuts,burnsorwornareasbeforeeachuse.Alsoinspectttingsfordamage.Ifanydamageisfound,replace

immediately.

8DO NOTrepairhoseswithtape.

9 Keepallthreadsandunionscleanandfreefromoil,dirtorgrease.

8 Neverapplyoilorgreasetoanythread.

9 Makesurebottlekeysareinplaceatalltimessothatintheeventofanemergencythevalvescanbeturnedoquickly.

9 LEAKINGHOSESCANKILL.Leaktestallconnectionsandvalvespriortoeachuseoftheequipment.

8DO NOTjoindamagedhoses,theymustbereplacedimmediately.

9 Rememberatalltimes BLUE=OXYGEN‘O’ RED=ACETYLENE‘A’.

8 Atnotimemayyouinterchangethispartwiththoseofothermanufacturers.

9 OnlySealeyreplacementitemsshouldbeused.

9 Allrepairs/calibrationsmustonlybeundertakenbyaBCGAapprovedserviceagent.

2. INTRODUCTION

Protectsoperators,regulatorsandgassupplyfromtheconsequencesofsevereformsofashback.Colourcodedforeasy

recognition.ItalsoconformstoBSENISO5175-1:2017standard.

Original Language Version

© Jack Sealey Limited

3. SPECIFICATION

Model No:............................... SGA3/FBA /SGA4/FBA

Gas Type SGA3/FBA: .......................................Oxygen

Gas Type SGA4/FBA..................................... Acetylene

MaximumPressure ..............................................20bar

4. DEFINITIONS

4.1. Flameashbackisfastmovementofametothesourceofgas

(Cylinder,tank,installation,hoseetc.)whichisformedduring

welding,cuttingetc.madebymixtureofoxygenandammablegas.

4.2. Flashbackarrestorsaresecuritydevices,whichpreventtheowof

gasduringashback.Thearrestorpreventstheamespreadto

gassourcebyblockingtheameandstoppinggasow.

5. FUNCTIONS REFER TO FIG.2

5.1. THERMAL CUT-OFF VALVE

Thespringinsidetheashbackarrestorblocksthevalvewhichiscontinuouslypressedagainstthegasowdirection.Whename

ashbackoccurs,thesolderwhichholdsthespring,meltswiththehightemperature.Thespringisthenreleasedandthe

connectedvalvestopsgasow.

5.2. FLAME ARRESTOR

Astainlesssteellterstopstheamereachingtheashbackarrestorandpreventsitreachingthesourceofgas.

5.3. GAS NON-RETURN VALVE

Preventsthegasowinginreversedirection.

5.4. WORKING PRINCIPLES

5.4.1. Thespringinsidetheashbackarrestorforregulatorsblocksthevalvewhichiscontinuouslypressedagainsttogasowdirection.

5.4.2. Thepressureoftheowinggasreleasesthecompressionofspringandpermitsthegasowthroughthetorch.

5.4.3. SinteredstainlesssteelCr-Nidesignedlterinsidetheashbackarrestorholdstheameforashback.

5.4.4. Thesoldermeltsduringanyameashbackifthetemperaturereaches100°C,pinfreesfromthesolderandcutsthegasow.

5.4.5. Afterthatashbackarrestorcannotbeusedanymoreandshouldbechanged.

6. ASSEMBLY REFER TO FIG.1

6.1. Checkallconnectionsthattheyarecleanandundamagedbeforeassembly.

6.2. Assembletheproductaccordingtothedirectionofgasow.

6.3. Checkforleakageatmaximumoperatingpressureafterassembly.

6.4. Hoses and their connections must meet current standards in place.

6.5. Hosesshouldbexedinasuitablemanner(e.g.hoseclamp).

6.6. Tightenthearrestorconnectionsusingasuitabletool.

▲DANGER: For the productswhichareusedforOxygen,allconnectionsandunitsshouldbefreeofgrease.

7. MAINTENANCE

7.1. Theashbackarrestorsaretobetestedbyaqualiedandauthorisedpersonatregularintervalsaccordingtoregulationsinplace.

7.2. Theashbackarrestoristobetestedforgastightnessandgasreturnaccordingtoregulationsinplace.

7.3. Couplingsarewearingpartsandhavetobetestedbyaqualiedandauthorisedpersonaccordingtoregulationsinplace.

Thesetestshavetobeperformedwhenthecouplingsconnectedaswellasdisconnected./TRANSPORTATION

7.4. Storetheproductinsidethepackageduringtransportationtoavoiddamage.

7.5. Productshouldbestoredinitspackaginguntilused.Keepawayfromgreaseandotherdirtsources.

7.6. Productsshouldbestoredintemperaturesbetween+5°Cand+35°Candkeptawayfromdustandhumidity.

8DO NOTuseproducts,whicharedamagedduringtransportationorstorage.

g.1

g.2

SGA3/FBA, SGA4/FBA Issue 1 16/12/2022

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 703534 sales@sealey.co.uk www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycleunwantedmaterialsinsteadofdisposingofthemaswaste.Alltools,accessoriesandpackagingshouldbesorted,

takentoarecyclingcentreanddisposedofinamannerwhichiscompatiblewiththeenvironment.Whentheproduct

becomescompletelyunserviceableandrequiresdisposal,drainanyfluids(ifapplicable)intoapprovedcontainersand

disposeoftheproductandfluidsaccordingtolocalregulations.

Note:Itisourpolicytocontinuallyimproveproductsandassuchwereservetherighttoalterdata,specificationsandcomponentpartswithoutprior

notice.

Important:NoLiabilityisacceptedforincorrectuseofthisproduct.

Warranty:Guaranteeis12monthsfrompurchasedate,proofofwhichisrequiredforanyclaim.

Original Language Version

© Jack Sealey Limited

REGISTER YOUR

PURCHASE HERE

8. TROUBLESHOOTING

No gas ow. Checkowdirection,workingpressure,shut-ovalve,gassource,cuto

valveandthecouplingisn’tlockedo.

Pressure sensitive gas cut-o valve PV. Agreencollarcoversaresetcollar.Inordertoresettheuserhastolook

forthecauseoftheashback,thenmovethesleeveinthedirectionofthe

arrow.Providingthecauseisfound,thesafetydevicecanberesetandwork

can resume.

The thermal shut o valve was activated TV. Thedevicehastobereplaced.

External tightness. Dustanddamagescancauseleakageofcouplingsandcouplingpins.

Therefore,theyhavetobecheckedaccordinglyandreplacedifnecessary.

Gas return NV. Thedevicehastobereplaced.

Leaking in disconnected situation. Unittobeexchanged(onlythosewithaintegratedcoupling).

SGA3/FBA, SGA4/FBA Issue 1 16/12/2022

This manual suits for next models

1

Table of contents

Other Sealy Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

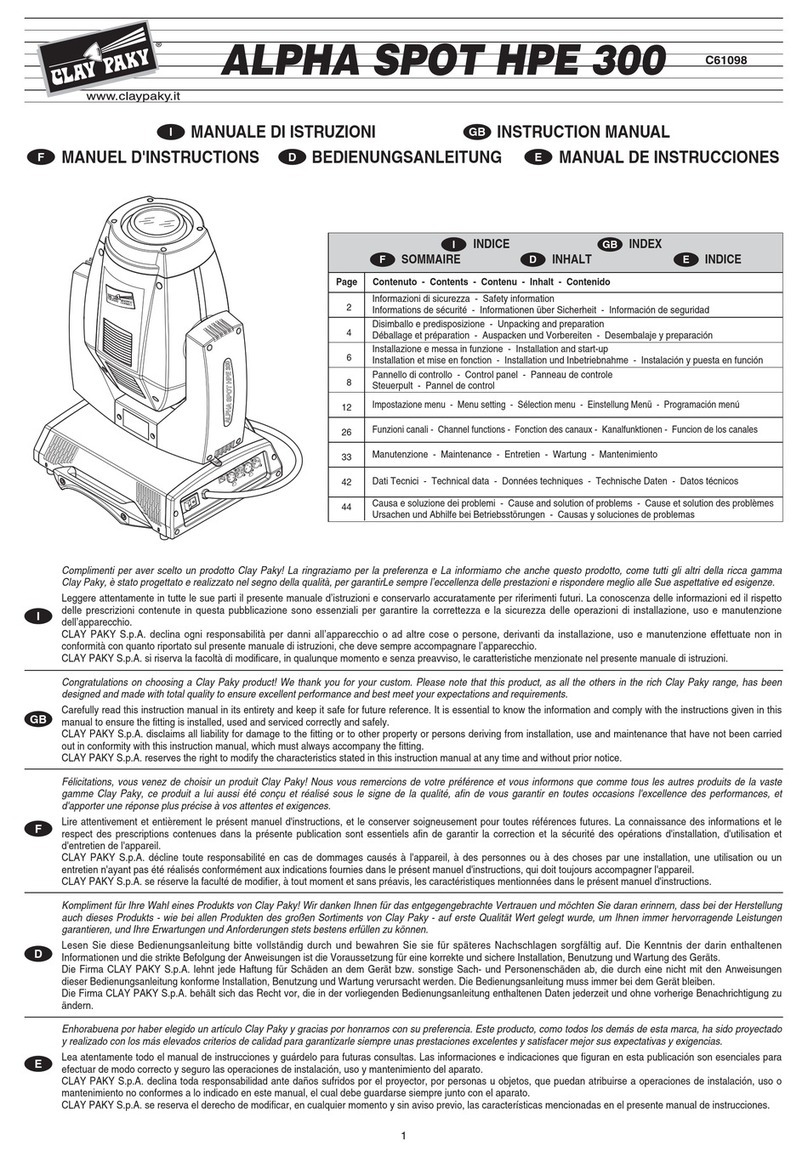

Claypaky

Claypaky ALPHA SPOT HPE 300 instruction manual

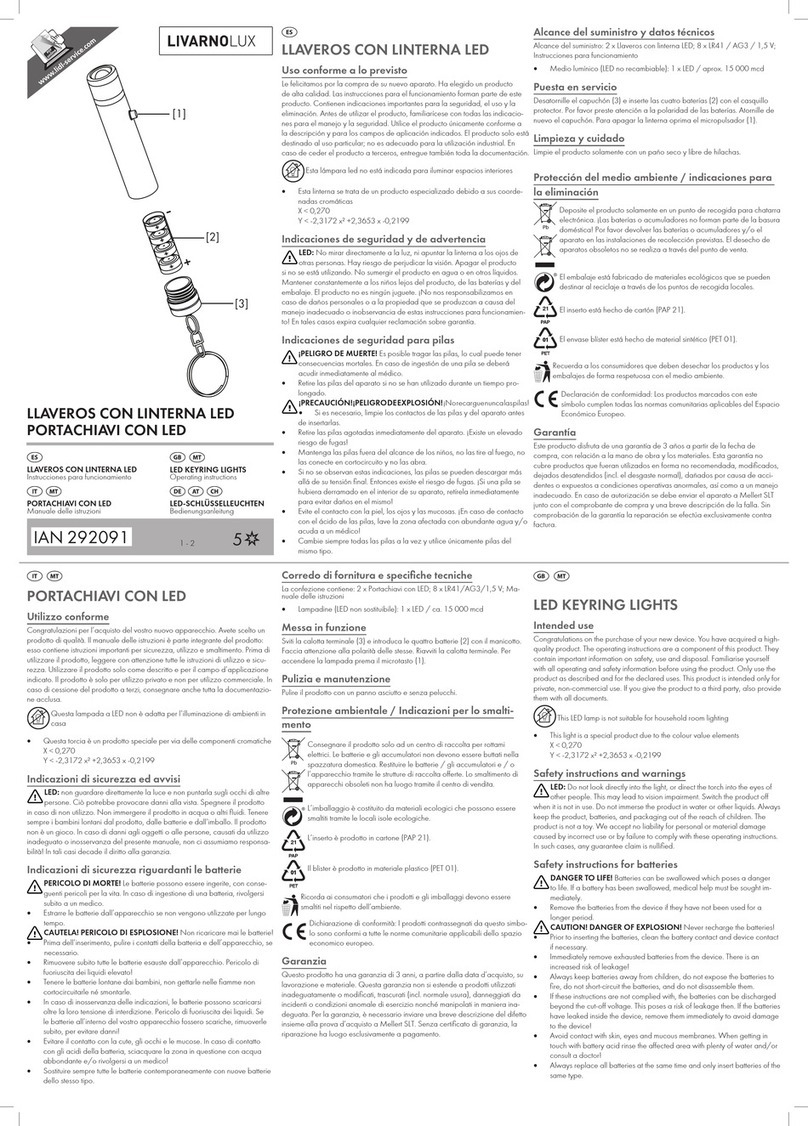

LIVARNO LUX

LIVARNO LUX 292091 operating instructions

HQ Power

HQ Power XMPL9 user manual

Lightmybricks

Lightmybricks 10317 installation guide

GOAL ZERO

GOAL ZERO Light-A-Life mini user manual

Astral Pool

Astral Pool 00081 Assembling and Installation Instructions