REFRIGERANT METERING DEVICE

CSPHP Models:

These coils have a factory-installed hard-shutoff TXV designed

only for use with R-410A refrigerant. Use only with outdoor

units designed for R-410A.

CSRHP Models:

These coils have a factory-installed hard-shutoff TXV designed

only for use with R-22 refrigerant. Use only with outdoor units

designed for R-22.

NOTE: ALL TXV'S HAVE PRESET SUPERHEAT

SETFINGS AND ARE FIELD NON-ADJUSTABLE.

Step l--Connect Condensate Lines

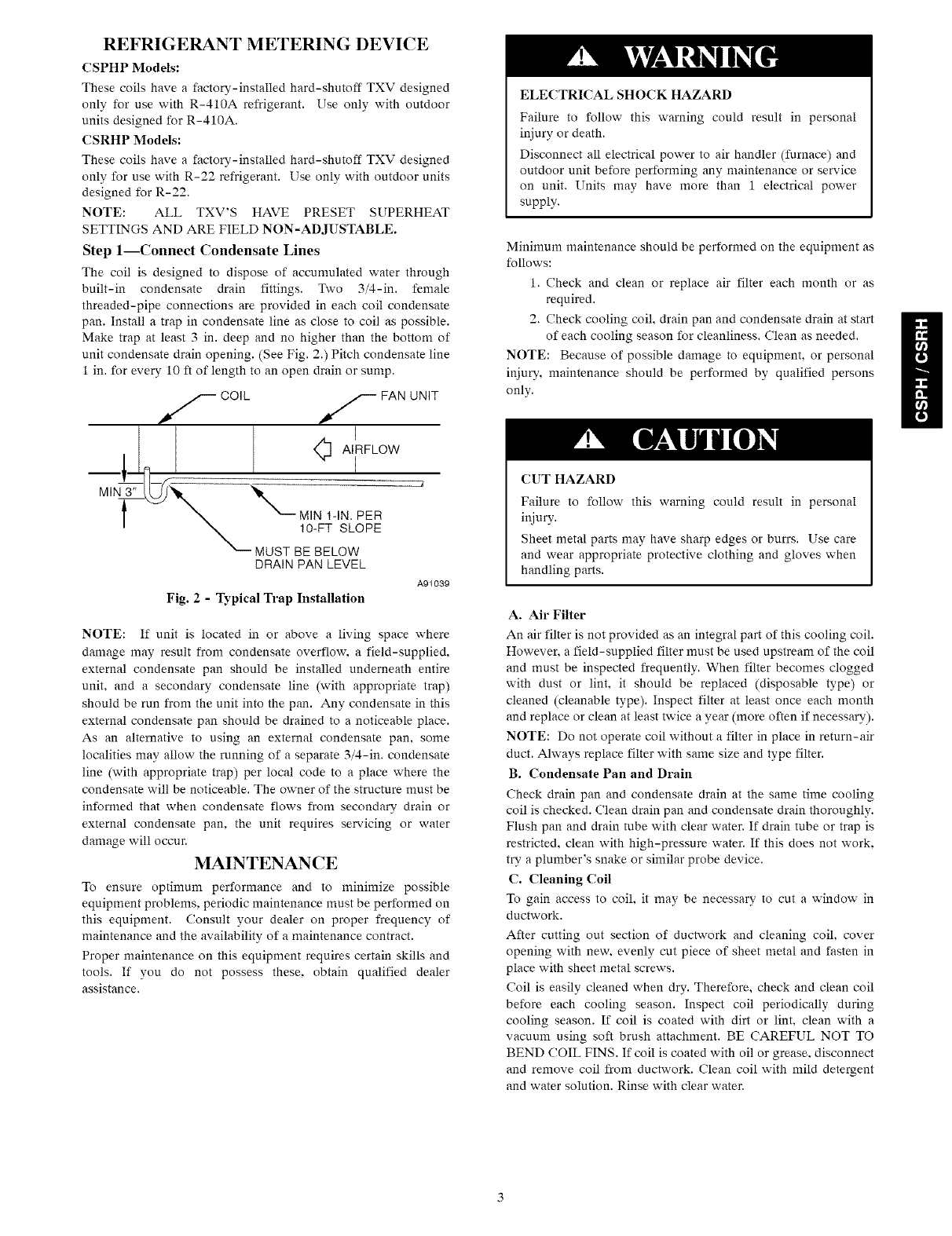

The coil is designed to dispose of accumulated water through

built-in condensate drain fittings. Two 3/4-in. female

threaded-pipe connections are provided in each coil condensate

pan. Install a trap in condensate line as close to coil as possible.

Make trap at least 3 in. deep and no higher than the bottom of

unit condensate drain opening. (See Fig. 2.) Pitch condensate line

1 in. for every 10 ft of length to an open drain or sump.

#_,S COIL f FAN UNIT

DRAIN PAN LEVEL

A91039

Fig. 2 -Typical Trap Installation

NOTE: If unit is located in or above a living space where

damage may result from condensate overflow, a field-supplied,

external condensate pan should be installed underneath entire

unit, and a secondary condensate line (with appropriate trap)

should be run from the unit into the pan. Any condensate in this

external condensate pan should be drained to a noticeable place.

As an alternative to using an external condensate pan, some

localities may allow the running of a separate 3/4-in. condensate

line (with appropriate trap) per local code to a place where the

condensate will be noticeable. The owner of the structure must be

informed that when condensate flows from secondary drain or

external condensate pan, the unit requires servicing or water

damage will occur. MAINTENANCE

To ensure optimum performance and to minimize possible

equipment problems, periodic maintenance must be performed on

this equipment. Consult your dealer on proper frequency of

maintenance and the availability of a maintenance contract.

Proper maintenance on this equipment requires certain skills and

tools. If you do not possess these, obtain qualified dealer

assistance.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect all electrical power to air handler (furnace) and

outdoor unit before performing any maintenance or service

on unit. Units may have more than 1 electrical power

supply.

Minimum maintenance should be performed on the equipment as

follows:

1. Check and clean or replace air filter each month or as

required.

2. Check cooling coil, drain pan and condensate drain at start

of each cooling season for cleanliness. Clean as needed.

NOTE: Because of possible damage to equipment, or personal

injury, maintenance should be performed by qualified persons

only.

CUT HAZARD

Failure to follow this warning could result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing and gloves when

handling parts.

A. Air Filter

An air filter is not provided as an integral part of this cooling coil.

However, a field-supplied filter must be used upstream of the coil

and must be inspected frequently. When filter becomes clogged

with dust or lint, it should be replaced (disposable type) or

cleaned (cleanable type). Inspect filter at least once each month

and replace or clean at least twice a year (more often if necessary).

NOTE: Do not operate coil without a filter in place in return-air

duct. Always replace filter with same size and type filter.

B. Condensate Pan and Drain

Check drain pan and condensate drain at the same time cooling

coil is checked. Clean drain pan and condensate drain thoroughly.

Flush pan and drain tube with clear water. If drain tube or trap is

restricted, clean with high-pressure water. If this does not work,

try a plumber's snake or similar probe device.

C. Cleaning Coil

To gain access to coil. it may be necessary to cut a window in

ductwork.

After cutting out section of ductwork and cleaning coil, cover

opening with new, evenly cut piece of sheet metal and fasten in

place with sheet metal screws.

Coil is easily cleaned when dry. Therefore, check and clean coil

before each cooling season. Inspect coil periodically during

cooling season. If coil is coated with dirt or lint, clean with a

vacuum using soft brush attachment. BE CAREFUL NOT TO

BEND COIL FINS. If coil is coated with oil or grease, disconnect

and remove coil from ductwork. Clean coil with mild detergent

and water solution. Rinse with clear water.