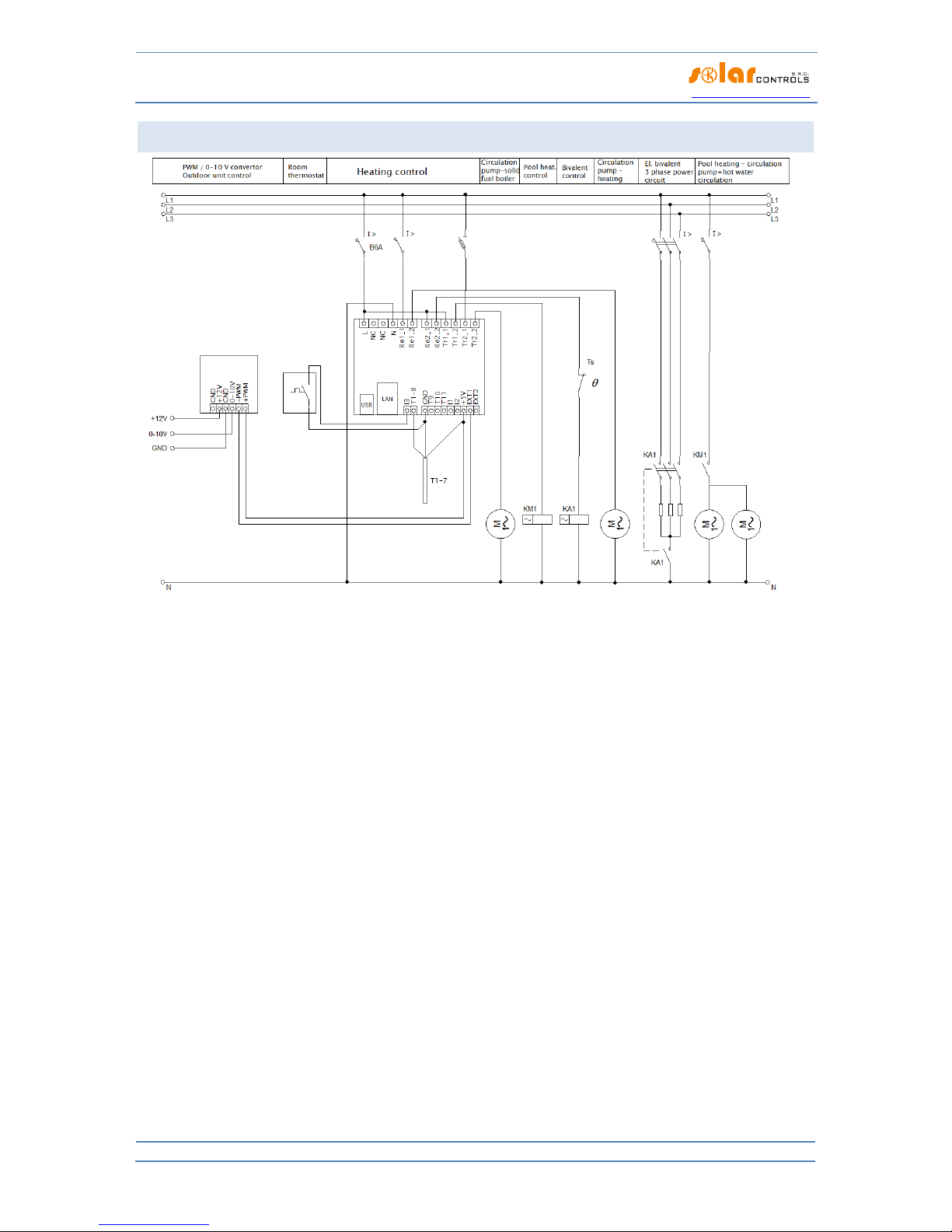

INSTRUCTIONS FOR THE INSTALLATION OF THE DEVICE

The Heating Control device can be installed into a standard secondary electrical distribution board by fixing it

on a 35mm DIN rail or by screwing it to a wall with two screws with round or countersunk heads of up to 6 mm

in diameter.

Use a conductor with a minimum cross-section of 0.5 mm2, e.g. CYKY 1.5, for connecting the controller power

supply (terminals L, N).

Use a shielded 3-core cable with a core cross-section of 0.5 to 1 mm2for connecting the digital temperature

sensors to GND terminals (earth), +5V (power supply) and T1-8 (data bus also designated as D/Q). Always

connect the sensor shielding to the GND terminal as close as possible to the controller. When connecting the

digital sensors to the bus, always also connect the shielding. When extending the bus, always use a separate

shielded cable, do not combine the shielding, for example, with the shielding of the analog temperature

sensors, digital inputs or Ext1 and Ext2 outputs! The total length of the bus, including all breakouts (sensor

cables), should not exceed 50 m.

Use a shielded 2-core conductor with a core cross-section of 0.5 to 1 mm2to connect the analog temperature

sensors between the GND terminal and the T9 terminal (T10, T11). Always connect the sensor shielding to the

GND terminal as close as possible to the controller. When extending the power supply, always use a separate

shielded cable, do not combine the shielding, for example, with the shielding of the digital temperature

sensors, digital inputs or Ext1 and Ext2 outputs!

If possible, connect the digital inputs by means of a shielded 2-core conductor with the core cross-section of

0.5 to 1.5 mm2between the GND terminal and the I1 (I2, I3) terminal. Always connect the shielding to the GND

terminal as close as possible to the controller. When extending the power supply, always use a separate

shielded cable, do not combine the shielding, for example, with the shielding of the analog or digital

temperature sensors or Ext1 and Ext2 outputs!

If possible, connect the external devices to Ext1 and Ext2 outputs by means of a shielded 2-core conductor with

a core cross-section of 0.5 to 1.5 mm2between the +5V terminal and the Ext1 (Ext2) terminal. Always connect

the shielding to the GND terminal as close as possible to the controller. When extending the power supply,

always use a separate shielded cable, do not combine the shielding, for example, with the shielding of the

analog or digital temperature sensors or digital inputs!

Connect the pumps, contactors, etc. to the Tr and Re outputs by means of conductors with a cross-section

corresponding to the input power of the connected equipment.

Figure 1: Description of the connectors and LEDs (a view from above).

Description of the controller terminals:

L –controller power supply, 230VAC/50Hz (it must be always connected)

N –neutral conductor (it must always be connected)

Re1 –relay output 1 –terminals 1 and 2

Re2 –relay output 1 –terminals 1 and 2