IAINTENANCE

1, FEATURE INFORMATION

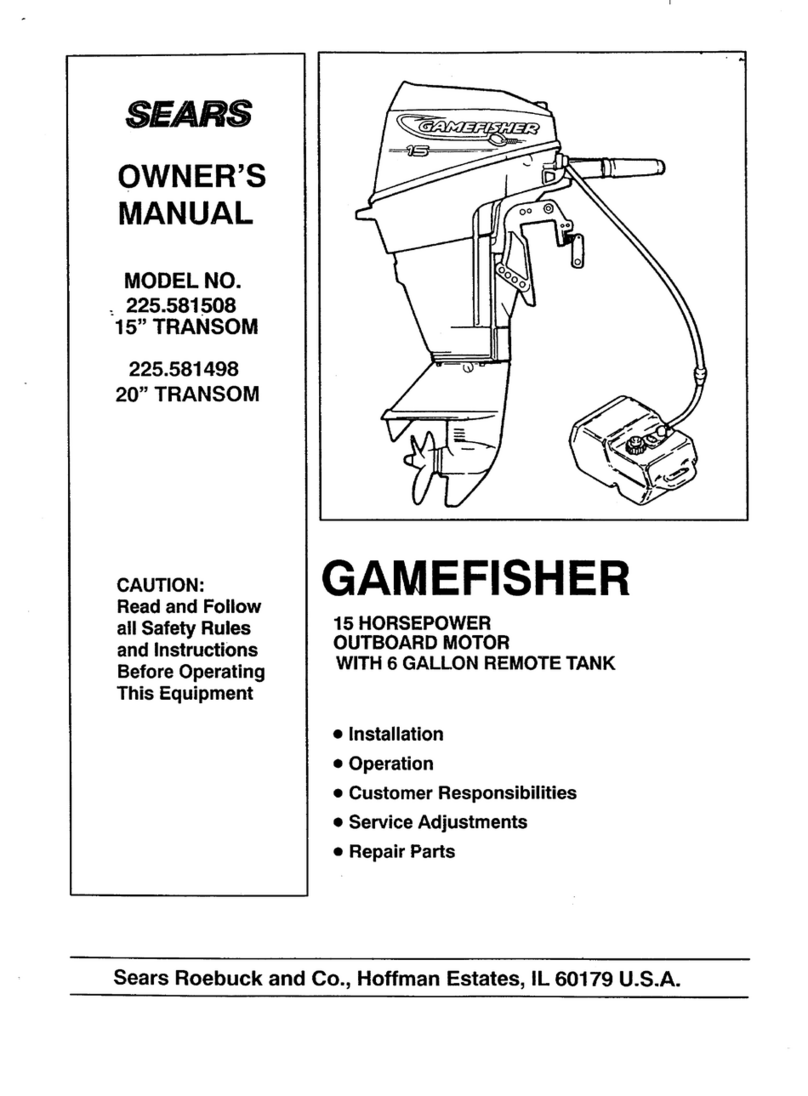

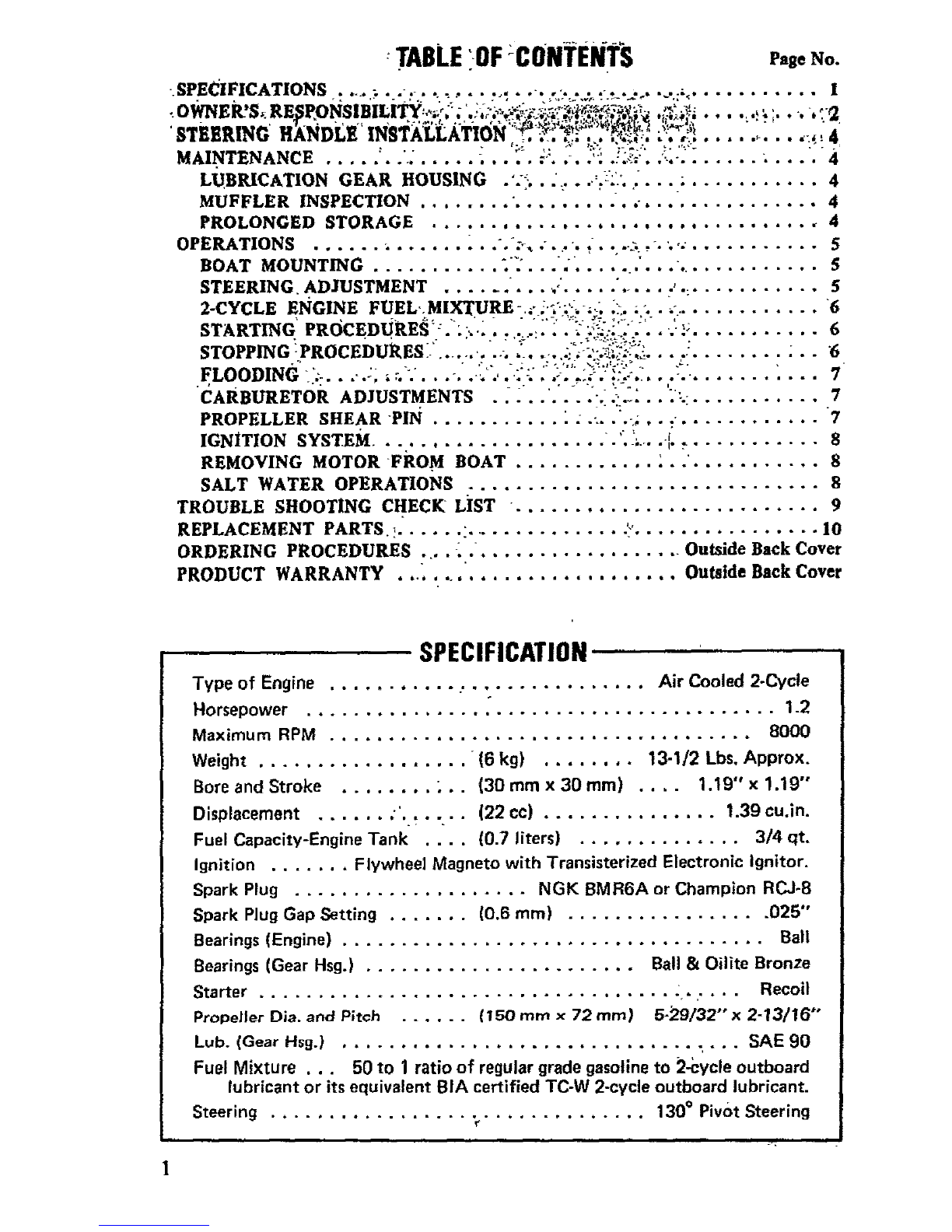

). This outboard motor has special design

features as shown in Figure 1.

}. Your selection of our Marine Products will

provide you with many hours of enjoyable

boating. To assure your complete satisfac-

tion on the in_estment you have just made,

we ask you to read this manual thoroughly

before going afloat. Acquaint yourself with

the particular areas of operation on your

outboard motor as you read the step-by-step

procedures. Keep in mind maximum per-

formance is achieved only when the owner

or operator is completely familiar with the

operatlng instructions.

:, Periodic servicing will be required. It is

recommended that you consult your Sear=

Service Center when service fs necessary.

We will be happy to extend our facilities

and assure prompt service.

_. STEERING HANDLE INSTALLATION

f

iRemove snap pln and washer 5 from steering

handle, screw handle mounting bolt in joint

pipe holder and stop steering handle. Then push

!groove at tip of steering handle against handle

stopper.

::Put washer 5 in over handle mounting bolt and

_insert snap pin.

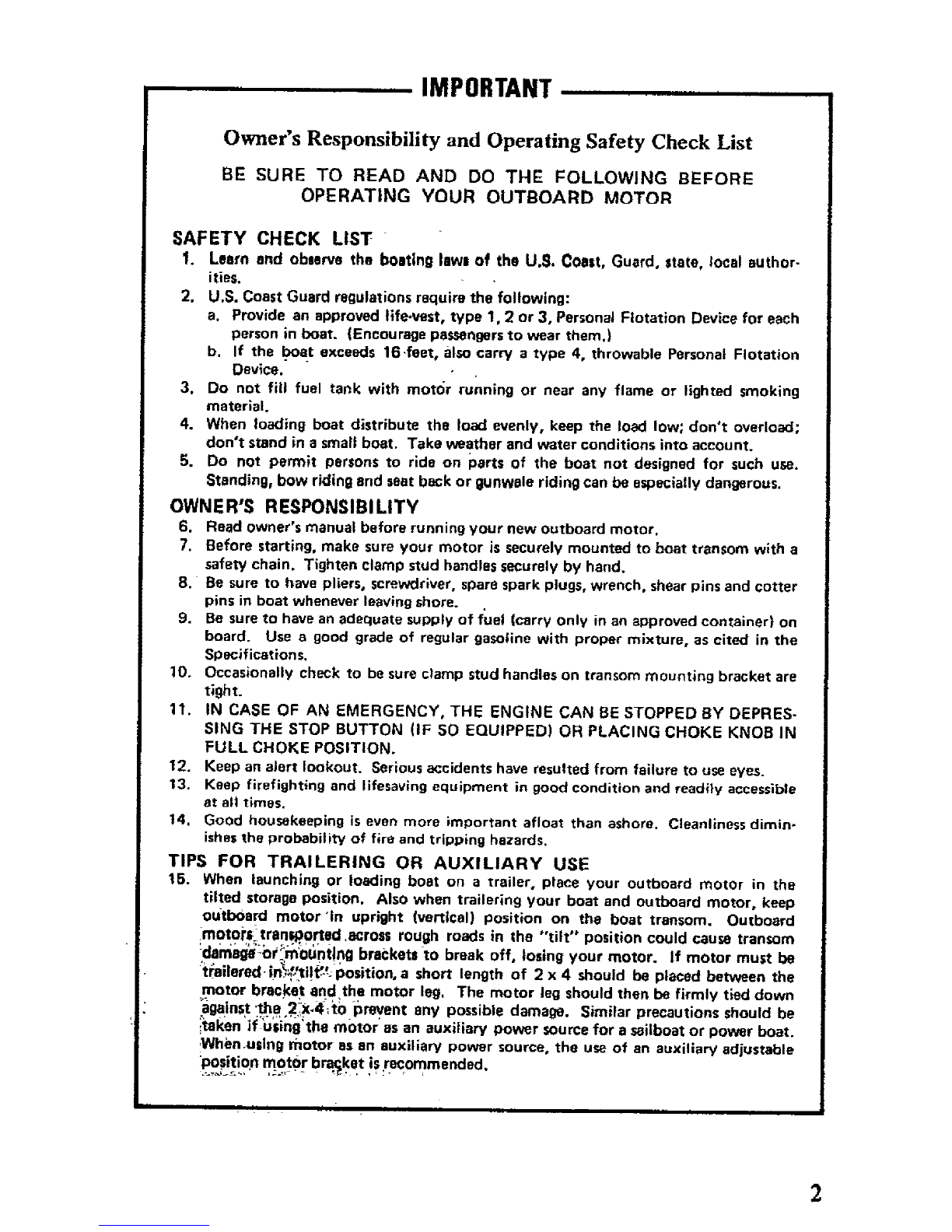

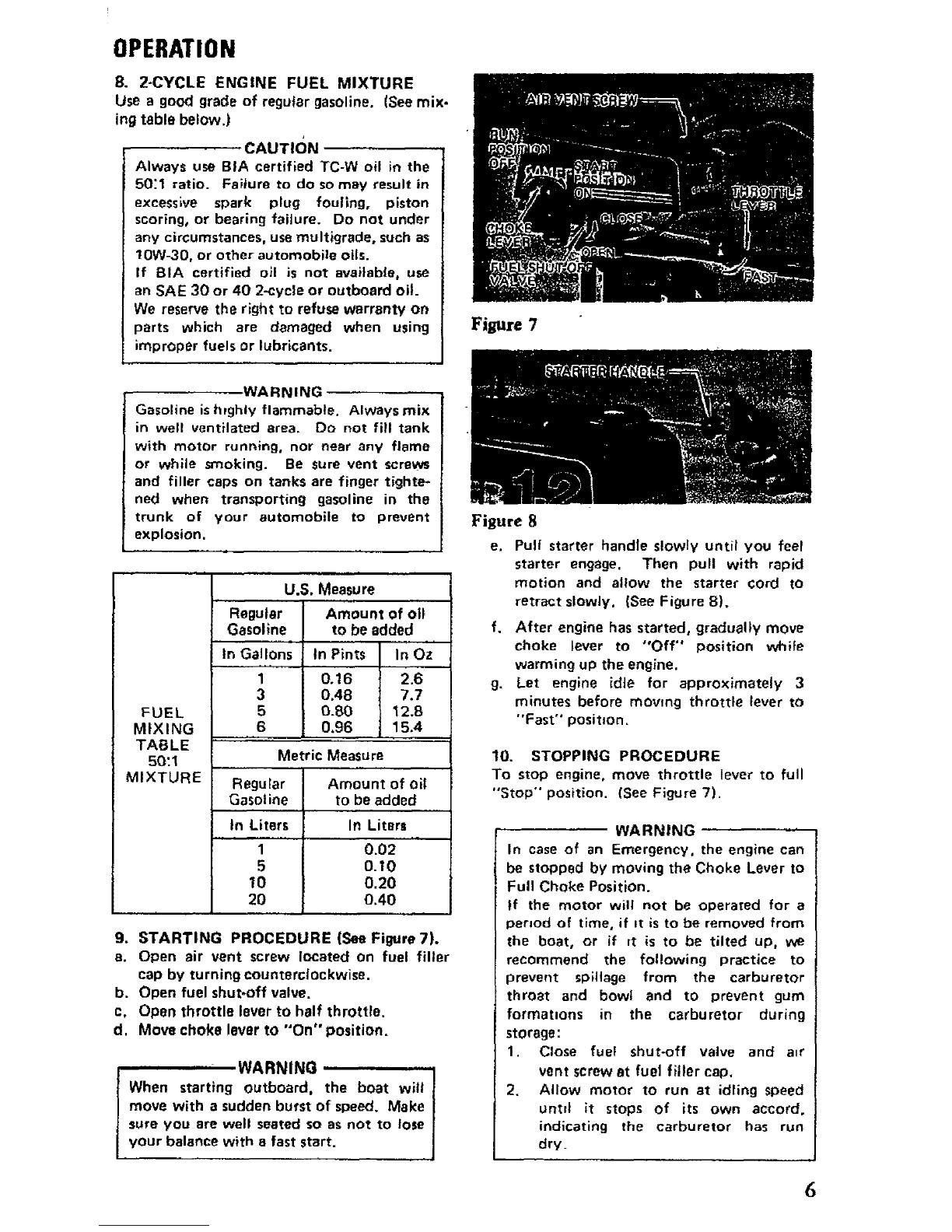

3, LUBRICATION -- GEAR HOUSING

a. The Gear Housing has been pre-lubricated at

the factory; however, the grease level should

be checked as follows using SAE 90 out-

board motor grease. (See Figure 2).

{1 ) oPrior to initial operation.

{2) After first four (4) hours of use.

(3) Recheck after every fifty {50) hours

running time.

(4) Replace with new lubricant pt the end

of your outboard motor season. This

is important, as it removes any water

from the gear housing and prevents

possible corrosion to internal parts.

b. To Check, Drainer Fill gear housing, follow

these steps:

(1) Position outboard motor upright.

(2) Remove drain plug and washer, then

_nsert nozzle of gear lubricant tube

Into hole.

(3) Squeeze tube until lubricant is forced

out around tube.

[4) Replace plug and washer. Be sure plug

is tightened securely,

(5) To achieve complete drainage of lubri-

cant, remove cotter pin, propeller and

shear pin from propeller shaft, also,

gear housing cover by unscrewing 2

bolts.

C,

(6) When lubricant has completely drained,

replace parts and refill gear housing

using filling procedure above.

For best results, lubricate propeller shaft

with lithium grease every 30 to 60 days.

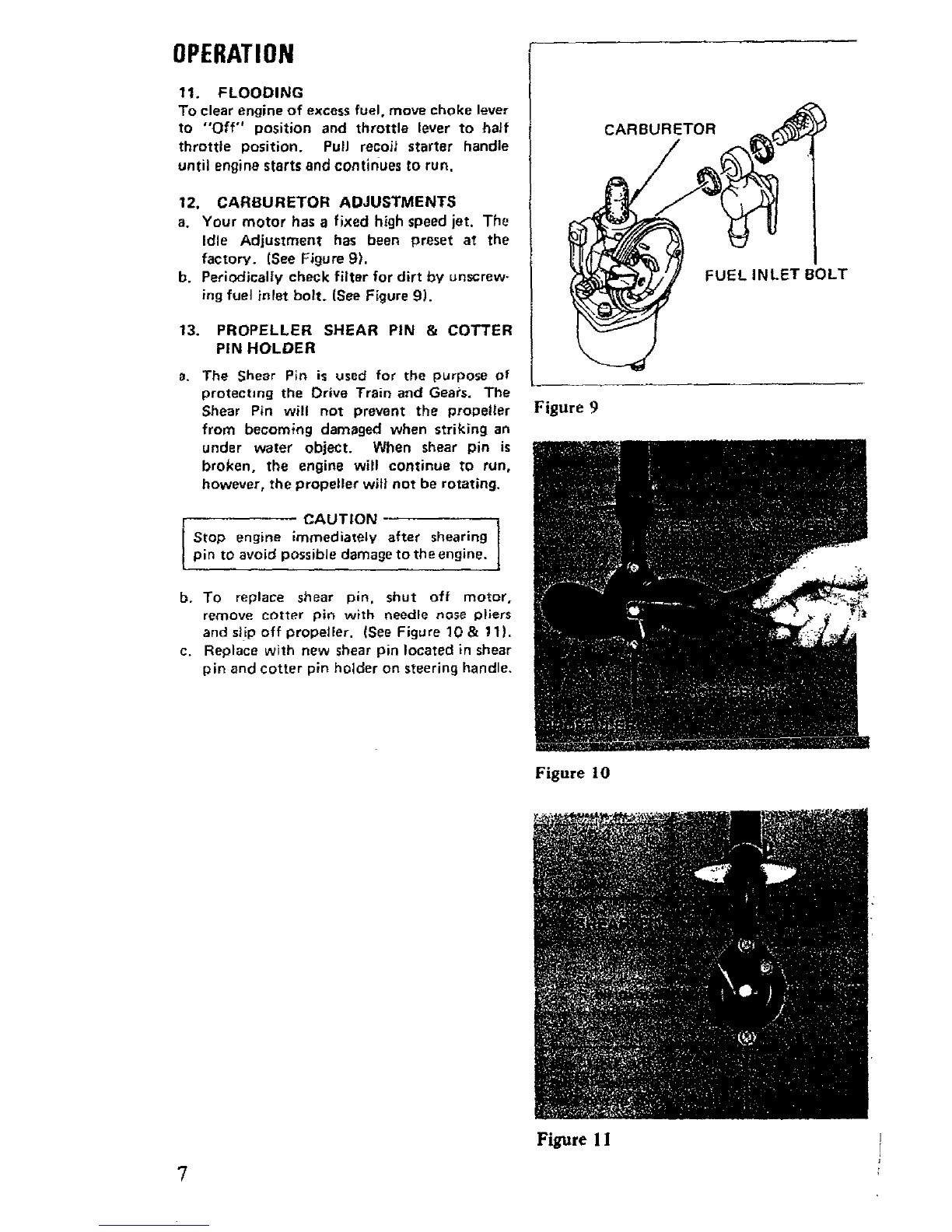

4. MUFFLER INSPECTION

a. Periodically remove muffler, cover by un-

screwing screws and inspect for carbon

build-up inside the muffler inlet and outlet,

the exhaust port and the combustion

chamber of the cylinder. Excessive carbon

wil! prevent drawing the maximum power

out of the engine. (See Figure 3).

b, Care should be exercised while cleaning

away carbon to prevent scratches to the

surface of the engine components and drop-

ping carbon inside of crankcase.

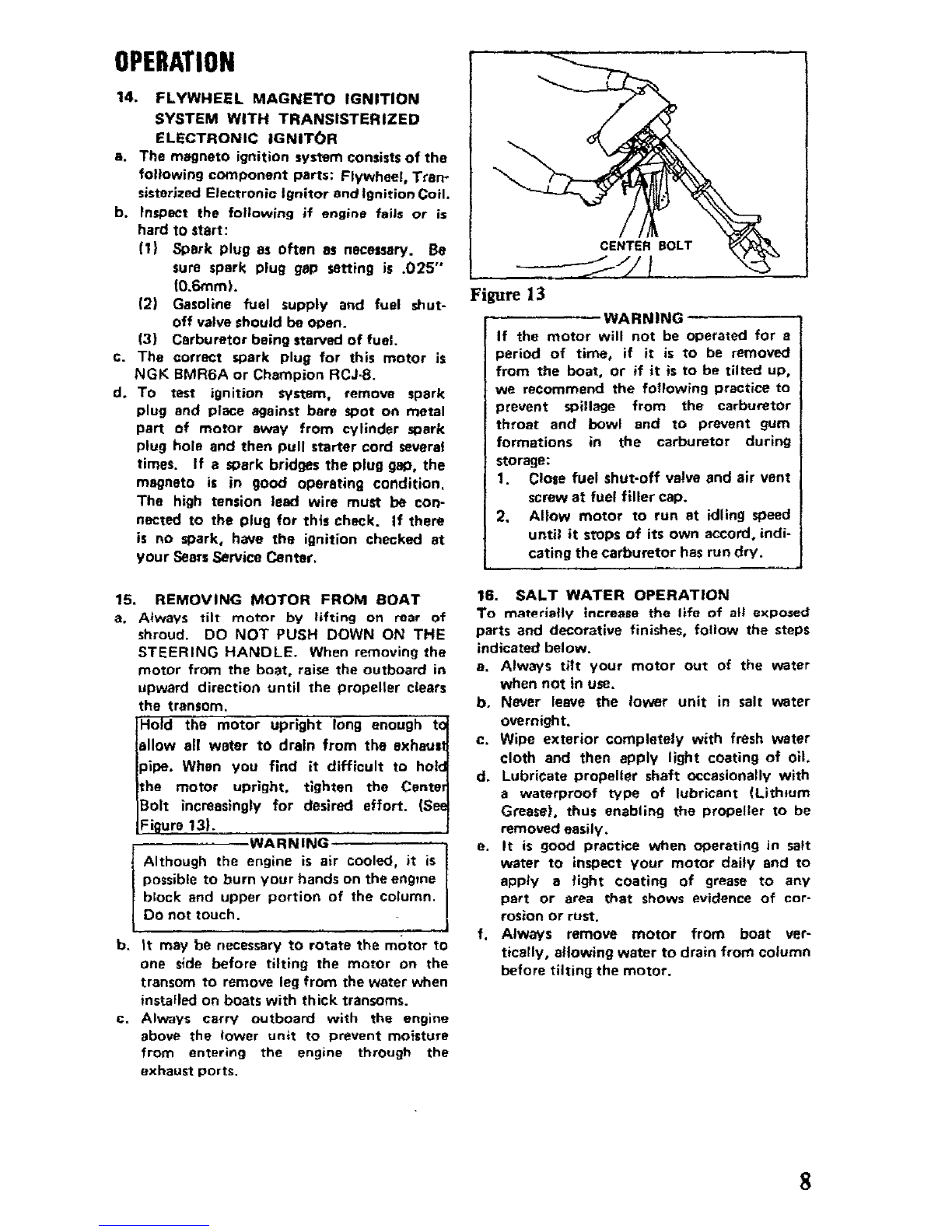

5. PROLONGED STORAGE

a. To store your outboard motor for pro-

longed storage, prepare outboard as fol-

lows:

(1) See paragraph on stopping procedures.

(Ref, 10)

(2) When removing outboard motor from

boat, allow atl water to drain from

unit.

(3) The outboard mercer should be

mounted on a stand vertically with

power head up for storage.

{4) Pull starter handle slowly until resist-

ance is felt due to compression pres-

sore, then stop. Release starter tension

slowly tO prevent engine from revers-

ing rotation due to compression

pressure. This position will close both

the intake end exhaust ports for

storage.

(5) Drain and fill gear housing as outlined

under Lubrication of Gear Housing.

(Ref. 3)

(6) Wipe exterior completely with fresh

water cloth and then apply light coat-

ing of oil.

b. When starting a new season, always use fresh

gasoline. Last year's gasoline may have

varnish deposits that will plug the carbu-

retor jets, thus requiring a complete over-

haul,

c, To plan for the coming season, we recom-

mend you contact your Sears Service

Center before the new season for any service

repair work required.