3

MAJOR COMPONENTS AND WHAT THEY DO

Tank and Air Volume Control

The tank serves two functions:

1. It provides a reservoir of water. Some of this water

isdrawnoffwheneverahousefixtureisopened(so

that the pump doesn’t need to start every time you

open a tap).

2. It maintains a cushion of air under pressure.

A standard tank requires an Air Volume Control

(AVC) to add air to the tank when needed. See the

instructions included with the AVC for details of in-

stallation and operation.

A SEARS Captive Air®tank maintains a constant

precharge of air in the tank and does not require an

AVC. An annual check on the tank pre-charge pressure

is recommended.

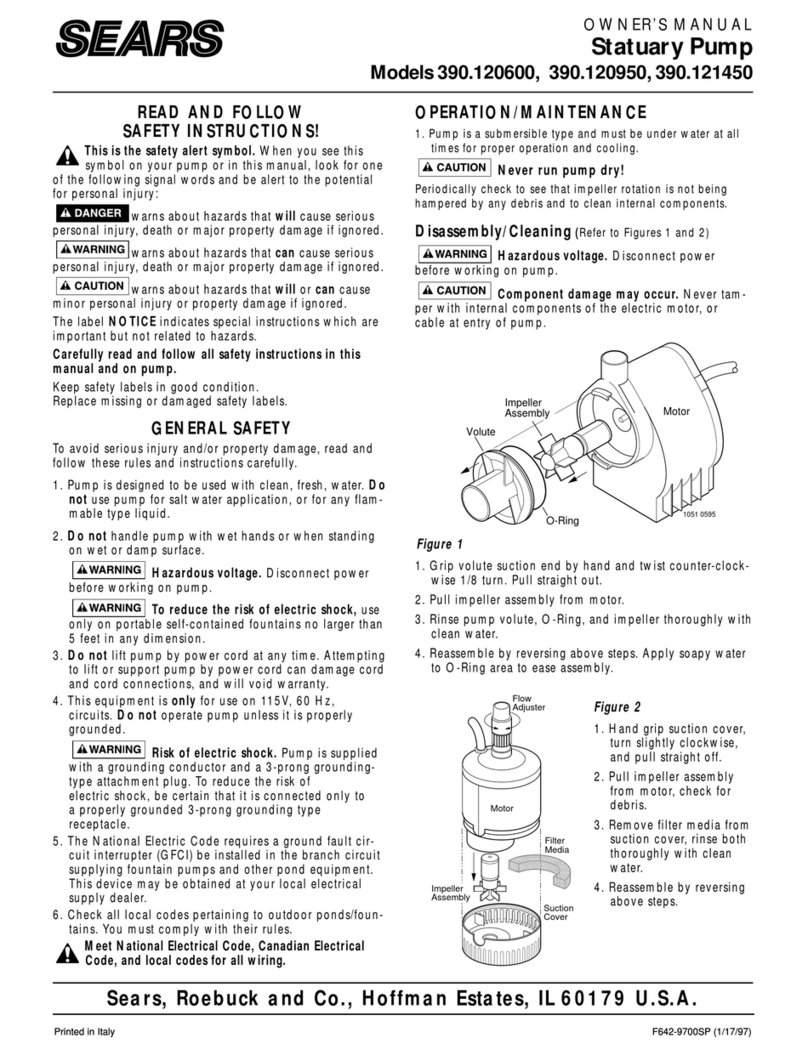

Impeller

The pump’s impeller rotates with the motor shaft,

causing the water to fly out from its rim by centrifugal

force. The rotation of the impeller, along with the mo-

tion of the water, creates a vacuum at the center of the

impeller (the “eye” of the impeller) which pulls in

more water.

The Vertical Multi-Stage (VMS) pump has two or three

(“multiple”) impellers; the water feeds through them

one after the other, with each impeller adding to the

pressure. This allows the VMS jet pump to pull water

from greater depths and at a higher pressure than a

conventional single stage jet pumps.

Jet

The jet is a nozzle/venturi arrangement installed in the

wellwhichdriveswaterupto thepump fromthe well,

boosting the water pressure going into the impellers.

The jet allows water to be lifted from a greater depth

than would be possible with only the impeller eye’s

vacuum. In order to drive the jet, part of the discharge

stream from the pump is diverted back “down the

hole” to the jet to help lift water from the well into the

pump suction.

Pressure Regulator

The pressure regulator is adjusted at installation to di-

vert the correct amount of water back to the jet for the

mostefficientoperation.Undercertain conditions, the

pressure regulator may require adjustment during the

pump’s life (see Page 10) to restore or maintain the

pump’s efficiency.

Pressure Switch

The pressure switch automatically starts the pump

when the pressure in the tank drops to 40 pounds per

square inch (PSI) and stops the pump when the tank

pressure reaches 60 PSI.

Adapter Flange

The VMS pump is equipped with an adapter flange.

This adapter facilitates installation and removal of the

pump without disturbing piping. See Pages 6 and 7 for

more information.

Pressure Relief Valve

Under certain conditions, VMS pumps can generate

veryhighpressure.Thepressurereliefvalveisinstalled

to make sure that the pressure in the system does not

exceedthe pressurewhichthesystemcan carry safely.

The pressure relief valve must be able to pass all the

waterthepump canproduce atthe system’sratedpres-

sure. Install a relief valve (Sears Stock No. 27229) set

to open at 75 PSI. between the pump and the tank.

There should be no shutoff valves between the pump

and the relief valve. See Figures 11 and 12, Page 8, for

more information.

Pump Mounting

The pump base has four equally spaced 3/4” NPT

threaded sockets. These will take threaded pipe for

legs, to allow enough room to make piping connec-

tions under the pump.

Inthecase of a single pipe installation (see below),the

pump can be placed directly over the well, using the

offset nipple furnished with the casing adapter to con-

nect the pump to the well head.

Piping

When installed on a ‘double pipe’ jet, one pipe is the

pressureordrivepipe;thispipesends waterdowninto

the well to the jet. The other pipe is the suction pipe;

this pipe carries water up to the pump suction from

the jet. Because of the pressure requirements and

depth of multi-stage jet pump installations, use the

chart below for pipe selection.

When installed on a singe pipe jet, the well casing

serves as the drive pipe, carrying water to the jet. The

drop pipe inside the well is the suction pipe, carrying

water up to the pump from the jet.

Usea ‘singlepipe’ systemfora2” or3” well;usea ‘dou-

ble pipe’ system for a 4” or larger well. See Pages 6 and

7 for details. Follow instructions packed with jet pack-

age to get proper nozzle and venturi combination for

your pumping depth.

Use 1-1/4” pipe for both suction and drive pipes. A 1”

nipple, a 1-1/4”x1” facing bushing, and a 1-1/4” cou-

pling are included in the jet package. These must be

used with the jet. (See Figure 8, Page 6, for installation

details.)