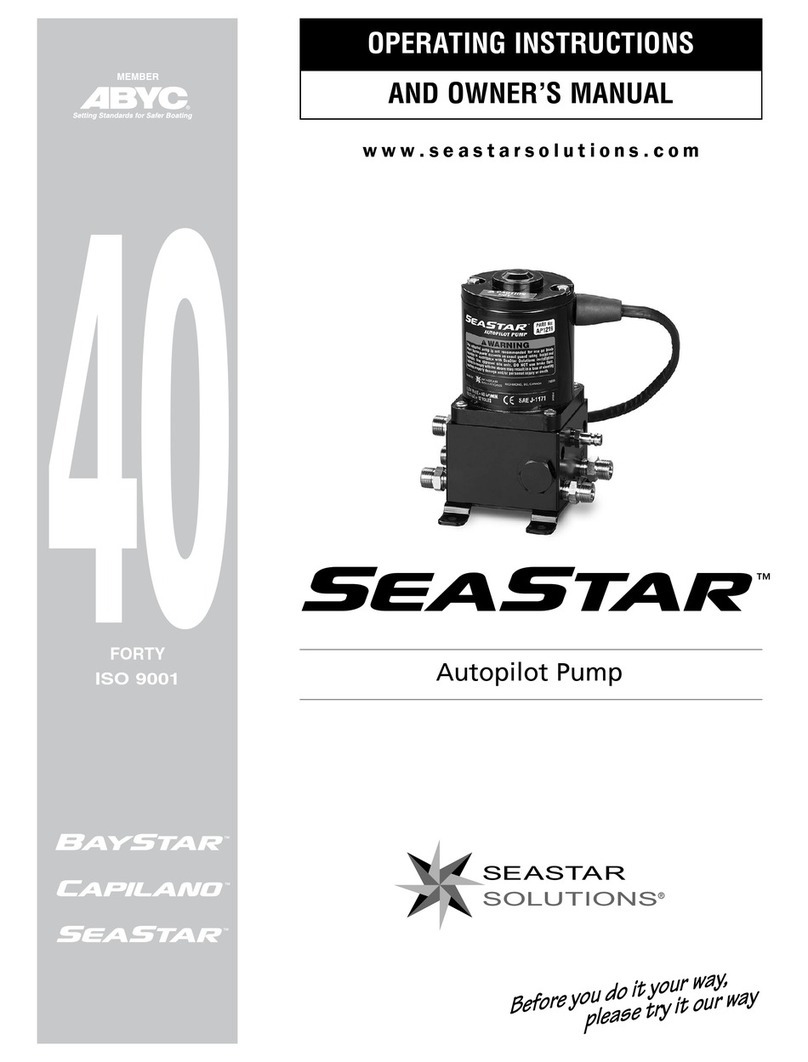

OIL LEVEL & SYSTEM CHECK

FILLER PLUG

(REMOVED)

FILLER KIT

HELM FILL

PORT

DO NOT LET

OIL LEVEL

FALL BELOW

THIS POINT

PUSH PIN

HYDRAULIC FLUID

Rcomm nd d oils for your st ring syst m ar ;

•S aStar Hydraulic Fluid, part# HA5430

•T xaco HO15

•Sh ll A ro Fluid #41

•Esso Univis N15

•Ch vron Aviation Fluid A

•Mobil A ro HFA

•Fluids m ting MIL-PRF-5606H sp cifications.

•Automatic transmission fluid D xron II may b

us d in an m rg ncy.

WARNING

NOTICE

Never use brake fluid. Any non-approved fluid may

cause irreparable damage, loss of steering, and

cancellation of warranty.

In cas s of xtr m m rg ncy any non-toxic, non-

flammabl fluid may provid t mporary st ring.

The oil level MUST be checked and maintained BEFORE

EACH use to ensure safe steering operation. Failure

to adhere to this warning may lead to loss of steering

control resulting in persons being ejected from vessel

or collision with an obstacle, leading to property

damage, personal injury and/or death.

WARNING

Side mount and Splashwell mount cylinders are unbal-

anced. To set the oil level in the helm pump the

cylinder rod MUST be fully “retracted (cylinder shaft

all the way in the cylinder body). Failure to adhere

to this caution WILL result in oil spillage at the helm

filler port and/or stiff steering operation.

CAUTION

•H lms mount d with th wh l shaft compl t ly

horizontal MUST b fill d to th bottom of fill r

hol AT ALL TIMES. DO NOT allow oil l v l to drop

mor than 1/4” b low fill r thr ads.

•For h lms mount d on a 20 d gr angl , or, with

wh l shaft in th v rtical position, oil l v l should

b within 1/2” of fill r hol .

•

Turn st ring wh l hard ov r to hard ov r to confirm

unr strict d mov m nt of th st ring syst m and

hos s. R p at this proc dur in ALL trim/tilt positions

of th ngin (s). If int rf r nc occurs, or, hos s

ar b ing str tch d this MUST b r mov d prior to

op rating your boat.

• Confirm that ngin (s) ar st ring to th prop r

dir ction wh n st ring wh l is turn d.

• If no int r f r nc is notic d, or, any int rf r nc

is corr ct d, go to n xt st p.

STEP 2 – System Chec

STEP 1 – Oil Level Setting

The system check MUST be completed after installation.

Doing so will ensure the safe operation of your steering.

Any fault/leak will be shown during this check. Failure

to adhere to this warning/check may result in loss of

steering control resulting in persons being ejected from

vessel or collision with an obstacle, leading to property

damage, personal injury and/or death.

WARNING

Failure to properly tighten the lock- nut (item 1) may

lead to loss of steering control. Loss of steering control

may result in unpredictable boat behavior, collision with

an obstacle and/or ejection from vessel, leading to

property damage, personal injury and/or death.

WARNING

SeaStar Solutions recommends that the hose and

hose fittings are checked on a regular basis to

ensure the safe operation of the steering system.

WARNING

Failure to complete the above noted step or, failure

to correct a problem may result in loss of

steering

control leading to ejection from the vessel or collision

with an obstacle resulting in property damage,

personal injury and/or death.

WARNING

NOTICE

This step will NOT harm the s stem and an noise

made during this step should not be considered a

fault in the steering s stem.

• Tak st ring wh l hard ov r to starboard (any

h lm can b us d on a multi-station boat). Onc

th wh l r ach s its stop point (cylind r is fully

strok d out), continu to forc th wh l on (1)

full turn past stop. L av wh l in this position

whil you ch ck all conn ctions, fittings, s als

and hos s for l aks.

• R p at to th Port dir ction and insp ct ALL

conn ctions, fittings, s als and hos s for l aks.

• If l aks ar notic d th y MUST b r pair d prior

to op rating boat. Aft r r pair r p at bl ding

proc dur s as outlin d in th st ring cylind r

manual.

POSITIONABLE ORB HOSE FITTING INSTALLATION/REALIGNMENT

NOTE: for straight ORB fittings simply torque fitting

to 18 ft-lbs. Fitting re-orientation not required.

1.

Back off lock nut (it m 1), count r-clockwis , until it

stops. NOTE: O-ring must be fully on sealing surface

and cannot contact any threads. Do not use Teflon

tape or any liquid pipe sealant with ORB fittings.

2. Thr ad fitting into h lm port until fitting wash r

(it m 2) contacts th fac of th h lm port.

Tight n hand tight. DO NOT USE A WRENCH.

Re-Positionable Pump Fitting Installation (if required.)

Installation

Figure 5. Figure 6.

Figure 4.

Ensuring that th st ring wh l will not int rf r with

any oth r functional quipm nt and you hav ad quat

spac “b hind” th dash for fittings and st ring lin

conn ctions, d t rmin your d sir d mounting position.

MOUNTING THE HELM

NOTICE

The helm ma be mounted with the helm shaft horizontal,

vertical or an angle between.

At ALL times the fluid cap MUST be in the

uppermost position.

SECURE WITH

WRENCH HERE

WHILE TIGHTENING

LOCKNUT (ITEM 1)

2

1

CAUTION

-3 helm pumps are fitted with positionable O-ring style

hose fitting ports (referred throughout this manual as

ORB). Do NOT attempt to install an NPT pipe fitting

into a -3 helm hose fitting port. Doing so will lead to

irreparable damage to the helm. ONLY use SeaStar

Solutions O-ring style hose fittings (ORB).

Figure 3.

Filling the helm full of oil can be done faster if oil is

poured into the helm prior to connecting filler tube

and oil bottle to the helm.

•Tap mounting t mplat to dash and us a c nt r

punch for locating r quir d hol s.

•

Drill th 3” diam t r hol and th four 5/16” diam t r

mounting hol s, position d as shown.

• To as installation, install your h lm hos fittings

into th h lm pump prior to mount.

See Positionable ORB Hose Fitting Installation.

•Ensuring th fill port is in th upp rmost position,

install h lm pump onto dash.

•

Install th four wash rs and four nuts onto th mounting

studs of th h lm pump. Torqu nuts to 110 in-lb.

THREAD FITTING BY HAND UNTIL

WASHER CONTACTS THIS FACE

•Using a good quality marin gr as , lightly gr as

tap r of th h lm pump shaft and mount st ring

wh l to h lm. Tight n wh l shaft nut to 150 in-lb.

• Install hos s as dir ct d in your st ring cylind r

installation manual.

• Fill and Purg st ring syst m as outlin d in your

st ring cylind r installation manual.

3. R -position fitting to d sir d ori ntation by turning

it count r-clockwis to a MAXIMUM of 1 full turn.

.

Whil holding th fitting body s cur ly with a wr nch,

torqu th lock nut (it m 1) to 18 ft-lbs.

5.Whil holding th fitting body s cur ly with a

wr nch, torqu th hos nd nut to 15 ft-lbs.

6. Purg syst m p r applicabl instruction manual.